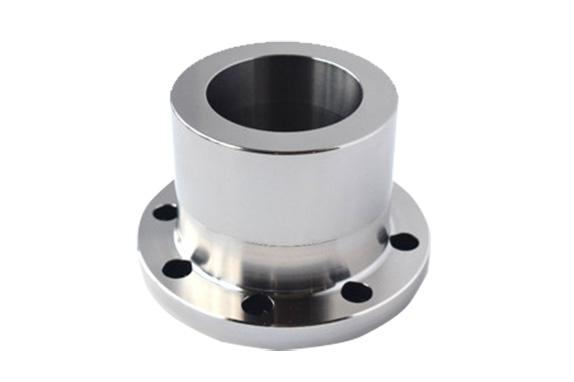

When a reputable canning and closure company required a redraw sleeve – a part demanding extremely precise machining and an aesthetic polished surface – they sought out Workrite Aerostar’s expertise. The intricate nature of this task, involving a carbide die pressed into a hardened steel body, required a high level of precision and attention to detail.

As experts in precision machining, we eagerly took on this challenge. The first hurdle was sourcing the appropriate material. Leveraging our supply chain network and procurement expertise, we secured the necessary materials within the client’s budget. This early win underscored our commitment to balancing cost efficiency and quality.

With materials at hand, our team dove into the intricate process of assembly and precision machining. Our skilled technicians and engineers, equipped with state-of-the-art machinery, navigated the complex task with accuracy and efficiency. This stage of the project was marked by a meticulous fusion of expertise, precision, and technological prowess.

Pressing the carbide die into the hardened steel body was the next step, demanding not only accuracy but a deep understanding of material properties. Our team’s successful execution of this delicate procedure further underscored our proficiency and attention to detail.

Upon completion, the parts were promptly delivered to the customer. Their response was a testament to our work – they lauded the speed, quality, and efficiency of our services. The satisfaction of our customer, mirrored in their ecstatic response, validated our position as leaders in precision machining.

This project highlights Workrite Aerostar’s commitment to delivering top-quality, efficient, and cost-effective solutions, reinforcing our unwavering dedication to precision, quality, and customer satisfaction.