Airset Sand Casting

Using airset sand casting processes, we produce aluminum castings that are highly resistant to corrosion, heat, abrasion, and wear. We can produce castings up to 1500 lbs. in weight. The aluminum parts are heat treated to provide high tensile strength. Our cast parts are typically used in engines, motors, pumps, and valves.

An extensive range of McEnglevan speedy melting furnaces, Tinker Omega & Castec sand systems and Castec 3-ton/hour shake systems are used for aluminum castings. Our average production volume ranges from 1 to 5000 units per year. In addition, we also handle custom, prototype, and short run requirements. We utilize real-time x-ray and material spectrometer to insure metal quality in our castings. We also perform assembly, finishing, inspection, and repair operations.

Capabilities

| Custom | Imported |

| Service Parts | Precision |

| Prototypes | Short Runs |

| Production | |

| Min: 1 Unit | Max: 5000 Units Per Year |

| Prototype to Low Volume | |

| Abrasion Resistant | Corrosion Resistant |

| Heat Resistant | Heat Treated |

| High Tensile | Wear Resistant |

| ANSI (American National Standards Institute) | ASME (American Society of Mechanical Engineers) |

| ASTM (American Society for Testing and Materials) | ISO (International Organization for Standardization) |

| ISO 9002 | ISO 9001:2000 |

| Mil-Spec (Military Specifications) | NMSDC (National Minority Supplier Development Council Certified) |

| NAIC (National Association of Insurance Commissioners) | 541614 |

| 541330 | RoHS (Restriction of Hazardous Substances Compliant) |

| TS (Technical Specifications, used with ISO 16949) | |

| AutoCAD (DWG, DWZ) | BMP |

| Catia (CATDrawing, CATPart) | DXF |

| GIF | IGES |

| IDW, IPT | ICD, ICS |

| JPG | MDX, MC8, MC9, SET) |

| PDES | |

| DRW, PRT, XPR | SAT |

| 3D ACIS Model File | SolidEdge |

| SolidWorks | STEP |

| SurfCam | TIFF |

Services and Processes

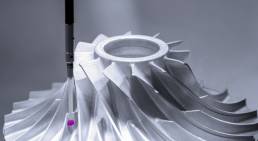

Sand casting produces rough metal castings using a mold usually made from sand formed around a replica of the object, also called a pattern, to be cast and is removed once the sand has been compacted.

| Assembly | Engineering |

| Finishing | Inspection |

| Machining | Repairs |

| BROTHER (TC-22A) | BROTHER (TC-32A) |

| BROTHER (TC-S2C) | BROTHER (TC-S2D) |

| DAEWOO (DHC 400) | DAEWOO (DHP 400) |

| DAEWOO (DMV 400) | DAEWOO (DVC 400) |

| DAEWOO (DVC 500) | DAEWOO PUMA (240 MS) |

| DOOSAN (HC 400) | DOOSAN (HP 4000) |

| DOOSAN (NHP6300) | HYUNDAI (HS6300) |

| HYUNDAI KIA # 1 (HS400) | HYUNDAI KIA # 2 (HS400) |

| HYUNDAI KIA # 3 (HS400) | HYUNDAI WIA # 1 (HS 4000) |

| HYUNDAI WIA # 2 (HS 4000) | HYUNDAI WIA # 4 (HS 4000) |

| HYUNDAI WIA # 5 (HS 4000) | HYUNDAI WIA (HS 4000i) |

| MAKINO (A51) | MAKINO (A55 # 1 DELTA) |

| MAKINO (A55 # 2) | MAKINO (A55E # 2) |

| MAKINO (A55E) | MAKINO (A66) |

| MAKINO (A77) | MORI SEIKI (SH-50) |

| MORI SEIKI (SH-500) | SHARP BRIDGEPORT |

| Southwestern Trak Lathe (TRL-1745P) | Southwestern Trak Mill (DPM) |

| TOYODA (FA400) | Mazak Quick Slant 30N 4 axis - Mazatrol Cam T-4 |

| DMC DL 80V | DMC DL 80VL |

| DAEWOO (Puma 300M-GL) | DAEWOO PUMA (240 MS) |

| DMG-MORI (450V1) | DOOSAN (QL300HM) |

| MORI SEIKI (SL-65A) | MURATA (MW 12) |

| MURATA (MW 120) | MURATA (MW 200/GS) |

| MURATA (MW200) | MURATA (MW200/G) |

| OKUMA HOWA (2SP-V35) | OKUMA HOWA (2SP-V55) |

| OKUMA HOWA (HL 20) | OKUMA HOWA (HL 35) |

| Hardinge Elmira N | LeBlond |

| Mazak 250 Matrix Nexus 2 | Mazak Quick Slant 30N 4 axis - Mazatrol Cam T-4 |

| Mazak Quick Turn 15 - Mazatrol T32-2 | Mazak Quick Turn Smart 350 |

| Mazak Super Quick Turn 30 2 Axis - Mazatrol T-32-2 | Poreba 48" Lathe - 48" Dia x 120" bet. centers - 30 HP Motor |

| Tool Mex TUR 630 M with Sony Readout | |

| Bryant Universal ID Grinder | Chavalier FSG 1632 TX Surface Grinder |

| TOS Hostivar BUB 50 OD Grinder | |

| MORI SEIKI (SL-65A) | MURATA (MW 12) |

| MURATA (MW 120) | MURATA (MW 200/GS) |

| MURATA (MW200) | MURATA (MW200/G) |

| OKUMA HOWA (2SP-V35) | OKUMA HOWA (2SP-V55) |

| OKUMA HOWA (HL 20) | OKUMA HOWA (HL 35) |

| Mazak 250 Matrix Nexus 2 | Mazak Quick Slant 30N 4 axis - Mazatrol Cam T-4 |

| Mazak Quick Turn 15 - Mazatrol T32-2 | Mazak Quick Turn Smart 350 |

| Mazak Super Quick Turn 30 2 Axis - Mazatrol T-32-2 | |

| BROTHER (TC-22A) | BROTHER (TC-32A) |

| BROTHER (TC-S2C) | BROTHER (TC-S2D) |

| HYUNDAI (HS6300) | HYUNDAI KIA # 1 (HS400) |

| HYUNDAI KIA # 2 (HS400) | HYUNDAI KIA # 3 (HS400) |

| HYUNDAI WIA # 1 (HS 4000) | HYUNDAI WIA # 2 (HS 4000) |

| HYUNDAI WIA # 4 (HS 4000) | HYUNDAI WIA # 5 (HS 4000) |

| HYUNDAI WIA (HS 4000i) | MAKINO (A51) |

| MAKINO (A55 # 1 DELTA) | MAKINO (A55 # 2) |

| MAKINO (A55E # 2) | MAKINO (A55E) |

| MAKINO (A66) | MAKINO (A77) |

| MORI SEIKI (SH-50) | MORI SEIKI (SH-500) |

| TOYODA (FA400) | DMC DL 80V |

| DMC DL 80VL | |

| OHIO BROACH (HC548) |

| DUNNAGE WASHER | RAMCO (MK32C) |

| RANSOHOFF (LEAN JET) | |

| Fryer MB-10 tool room mill | LABLONDE |

| SHARP BRIDGEPORT | Southwestern Trak Lathe (TRL-1745P) |

| Southwestern Trak Mill (DPM) | VECTRAX MILL (GS20F) |

| Bryant Universal ID Grinder | Chavalier FSG 1632 TX Surface Grinder |

| Dake 10 ton Hydraulic Press | Dake Arbor Press |

| Dake Johnson Band Saw VH-24 | Darex Tool Sharpener |

| Epilog Laser 20 watt | Gagemaker |

| Gaging | Hardinge Elmira N |

| Harig B/P Surface Grinder 618 Hogger 6 x 18 travel | Lap master 20c |

| LeBlond | Poreba 48" Lathe - 48" Dia x 120" bet. centers - 30 HP Motor |

| Safina Linear Hone | Sunnen Hone MBB-1660 / Sunnen PG-800E Precision Bore Gage |

| Tool Mex TUR 630 M with Sony Readout | |

| Height Master | Kodak 14" Optical Comparator with Readouts |

| Kodak 30" Optical Comparator with Readouts | Togoshiseike Hardness Tester / Rockwell style |

| Zeiss Contura | Zeiss Model 2840 w/Probe changer / 26 Position Probe Changer |

| DANA (JRI MCCS-1500) |

| Cad/Cam System w/plotter | Coolant Recovery System |

| Giant Tumblers | Granite Surface Plates |

| Material Handling Equipment | Power Washer / Steam |

| Sand Blaster | Sullair 250 air dryer |

| Sullair S-Energy 3700 Air compressor | WF Wells BF-20 Bar feed |

| Yale Fork lift ERC-080 8000# | |