Forging 101: What is Forging?

New to forging? Here is a breakdown:

According to IQS Directory:

What is Forging?

"The ancient art of forging falls into two distinct categories – hot and cold where hot forging has been around for centuries while cold did not begin until the industrial revolution of the 19th Century. Though they are quite different processes, the end results are the same. Forging is a method for deforming metal into a predetermined shape using tools and equipment where deformation is achieved using hot, cold, or warm forging processes. The determination of which process to use depends on the metal and desired shape of the final product.

Hot Forging and How It Works

"Hot forging takes place when a piece of metal is superheated beyond its crystallization point. The average temperature at which this happens depends on the type of metal where steel crystallizes at up to 1150o C, aluminum alloys between 360o C to 520o C, and copper alloys between 700o C to 800o C. The required temperature must be maintained above the recrystallization point or the point at which the metal begins to cool. Recrystallization can form microscopic crystals that warp when the metal is reheated causing it to 'strain harden', which makes it unworkable.

"Environmental factors can influence the hot forging process where contact with the atmosphere can cause oxidation. To avoid this, forging may be completed in an environmentally controlled chamber or isothermal forging, which is similar to a vacuum.

"The main advantage of hot forging is the strength a metal gains. Metals hot forged have a strong ductility, the ability to be significantly deformed and reshaped giving them a stronger resilience to tensile stress. Parts made using hot forging are stronger because the forging process changes the internal grain of the part changing its form and strength characteristics.

Things to Consider When Choosing Hot Forging

"Hot forging is used in the production of several different components and parts since the process can produce high precision and complex shapes. It is ideal for metals that have a high formability or can easily be deformed. Metals formed in hot forging gain strength and become more durable. It is a flexible process that is capable of producing customized parts. The excellent surface finishes of hot forged parts allows the use of different forms of finishing and polishing processes.

"Some of the unique results from hot forging include the ability to easily produce discrete pieces, low to medium accuracy, the formation of scale on the metal, low metal stress levels with lower work hardening temperatures, grain homogenization, higher ductility levels, and the elimination of chemical incongruities in the metal.

Negative factors of hot forging:

"Regardless of how productive hot forging is, it does have certain disadvantages that need to be considered. During the cooling process, there is always the possibility that the metal may warp and become brittle. There are some metals that should not be used in hot forging since it may produce less precise tolerances as well as variances in the grain structure.

"Though there are disadvantages and drawbacks to hot forging, it is well suited for producing aerospace products and airplane parts. The softness created in metals makes them easy to shape and produce intricate patterns required by those industries.

The Benefits of Cold Forging or Forming

"Cold forging refers to a metal shaping and deforming process that is performed at or slightly above room temperature where the temperature is kept at near three tenths of the recrystallization point of the metal. Squeezing, bending, shearing, and drawing are the most common cold forging methods. Soft metals such as aluminum or copper are ideal for the process.

"The method of cold forging uses compressive force to shape the workpiece by hand or machine. In many cases, the metal is pushed into a die shaped in the form of the final product. It is less expensive than hot forging and produces completed products that require little, if any, finishing. With aluminum, after being cold forged, it is heat treated to strengthen the piece, a process known as 'tempering'.

The Unique Process of Cold Forging

"The most common metals in cold forging are standard or carbon alloy steels. It is used to produce small, high volume products like fasteners such as nails, screws, rivets, and such. The lack of the need for heat makes it inexpensive and efficient. The types of cold forging methods used depends a great deal on the metal and the required shape. Below are descriptions of some common cold forging processes.

Impression die forging

"A common form of cold forging is impression-die forging, where the metal is placed into a die attached to an anvil. The metal is struck by a hammer to force it into the die. Depending on the product, the hammer may be dropped several times in rapid succession.

Squeezing

"Squeezing, also known as sizing, minimizes the thickness of metal by the application of pressure, which is determined by the sizing area, type of metal, and necessary needed change in the metal’s thickness. It is normally done to give a forged piece dimensional accuracy.

Cold rolling

"Cold roll forming produces more attractive finished surfaces with closer tolerances in a variety of shapes that can easily be galvanized, painted, or powder coated. Thin sheets of a metal, usually steel, are rolled into shapes such as floor and roof paneling, C, or Z shapes.

Drawing

"Drawing uses tensile forces to pull or stretch a metal to a particular shape or thickness. There are two forms of drawing – sheet metal and wire, bar, or tube. Drawing can only be applied to certain types of metal or materials that have sufficient tensile strength. Though it may seem similar to cold rolling, it differs in the amount and position of the applied force.

"Cold forging has other processes designed for shaping metals. The ones listed here are common but only a few of the many that are in use. It is a popular process with auto manufacturers for the production of steering and suspension parts, certain braking systems, axles, and many other automobile parts.

Things to Consider When Choosing Cold Forging

"There are several benefits when considering cold forging. First, it is done at room temperature and does not require heating the metal, which helps to keep the cost of individual parts to a minimum. All of the equipment associated with hot forging such as blast and industrial furnaces are not necessary.

"Parts produced using cold forging are manufactured quickly and uniformly with superior dimensional control making it appealing to companies that have high volume and require quick turnaround times. With the use of computerization, every manufactured component is exactly the same in every detail and intricacy. Dies used for cold forging last longer since they do not have to endure the stress and wear of hot metals.

"The cold forging process is more precise and produces precision parts with high tolerances. The compliance with design specifications increases the uniformity of every part with less likelihood of flaws or errors that would require repeating production runs, and parts have a superior grain structure.

"An important factor, in this era of environmental concerns, is the eco-friendliness of cold forging since parts are shaped and formed under high pressure at room temperature. Unlike other processes, cold forging ensures that there will not be air bubbles or other deformities trapped in the workpiece.

"Some of the other benefits of cold forging include improved material usage, lower energy costs, and little to no finishing. With the rising costs of energy and the shortage of materials, cold forging is the solution to producing parts efficiently reducing the effect of those factors."

How Engineering Can Help Reimagine Public Health

It is easy to overlook how engineering impacts various areas of our lives, but it is important to consider how it can help the public health sector.

According to Manufacturing.Net:

"Of the many things that COVID-19 has made abundantly clear to us, surely one of them is a newfound realization that public health has become increasingly complex. Understanding the challenges to public health – that is, the task of guarding the well-being of the U.S. population – is essential now more than ever.

"As an engineer, design futurist and graduate program director, I have seen how COVID-19 has transformed how public health preparedness is viewed and understood. Some say the pandemic has delivered an urgency for a reimagining of public health.

"From problems in producing PPE that demonstrate the vulnerabilities in critical supply chains to solutions in vaccine distribution challenges that leverage innovative public-private partnerships, new perspectives and approaches to public health are necessary.

"A way to accomplish this: using health care engineering, or more specifically, the application of systems engineering in health care. Systems engineering is defined as an interdisciplinary approach and means to enable the realization of successful systems. These could include such complex systems as aircraft and spacecraft systems. Already, this concept is flourishing. Research centers throughout the U.S., including those at the Mayo Clinic and Northeastern University’s Healthcare Systems Engineering, suggest challenges such as patient safety could be made better by applying systems engineering principles and techniques through more holistic and human-centered approaches to systems design.

"These efforts have proven helpful to health care delivery in response to COVID-19. But more is required, particularly in the use of systems engineering in informing public health responses and interventions. A field of public health systems engineering is needed.

"Its intent: to develop and apply systemic and integrated approaches to understanding and solving public health problems. Formalizing a field of public health systems engineering – focused on health care at the population level – offers the needed research and educational pathways to advance this work.

The systems engineering imperative

"Examples of this include designing and developing personal protective equipment, repairing the vulnerabilities in the food supply chain, and grappling with vaccine logistics. COVID-19 has made clear the growing interconnected, interdisciplinary and multifaceted nature of public health’s future. In partnering with public health, systems engineering can mature mindsets (systems thinking) and practices that can aid in meeting this future.

"Illustrating this notion are efforts by Pinar Keskinocak, the co-founder and director of the Center for Health and Humanitarian Systems at Georgia Institute of Technology, and her colleagues. In a recent interview, Keskinocak said: 'Whenever there is a complex problem, it needs serious analysis or technology and that’s where an engineer comes in. This is exactly the situation now, very complex, dynamic and uncertain. It’s difficult to understand what’s going on or make decisions just by sitting around a table and discussing. We need expertise in engineering.'

"And it’s not just technical or technological concerns. Human systems integration or human factors considerations are equally central in systems engineering approaches. For example, building trust with Black Americans is vital to the success of contact tracing. Public health systems engineering could advance efforts to develop more equitable practices that could improve Black participation. An example is works that further the development of requirements elicitation techniques such as storytelling that provide a more comprehensive understanding of users and their context of use. These more inclusive practices would consider historical context and support more community-led public health design engagements.

A ‘test we cannot fail’

"COVID-19 has often been called a stress test for public health. COVID-19 will not be our last or worst pandemic; our emerging understanding of the public health implications of climate change further spotlights this growing need. 'What is true for COVID is true for climate change,' says a recent Scientific American opinion piece. 'We’re not prepared. Part of the gap is a knowledge gap: We haven’t done the needed research, and we lack critical information.'

"As the future of public health is likely to become increasingly digital, the technical understanding and holistic approach offered by systems engineering will begin to fill this critical public health knowledge gap. Fortunately, efforts are emerging in meeting these needs. Emory University’s Health DesignED, the Design Institute for Health at the Dell Medical School, Vanderbilt’s Medical Innovators Development Program and recent initiatives such as those at Johns Hopkins are examples. The time is ripe for evolving the field of public health systems engineering. It is something the U.S. public health system desperately needs."

Computer Numerical Control (CNC) Machining: What is CNC?

By now you have probably heard of CNC machining, but do you know what it is?

According to IQS Directory:

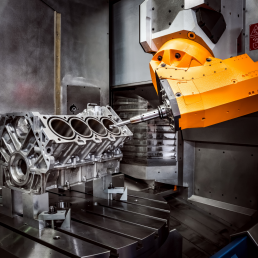

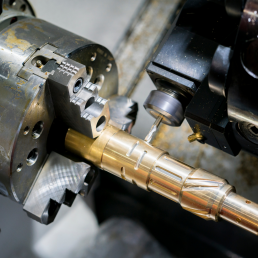

"The CNC process, computer numerical control, is a method of manufacturing where programmed software directs the operation of factory tools and machinery. It is designed to manage a wide range of complex machines from grinders and lathes to mills and routers. The purpose of CNC is to overcome the limitations associated with manual operation of machinery where buttons, levers, controls, and wheels have to be hand activated. In concise terms, CNC is three dimensional cutting completed by a single set of programmed instructions.

"CNC Machines operate using a numerical control system where a software program controls production. The language for the process is written in G code and controls the multiple operations of a machine. CNC allows an operator to pre-program the performance of a machine to complete repetitive, predictable functions. The accuracy and efficiency of CNC has made it a popular manufacturing method primarily in the metal fabricating and plastic production industries.

"The programming of CNC begins with a CAD rendering that is translated into a computer language for the CNC system. To determine the effectiveness of the programming, the machine is put through a trial run to detect any flaws or bugs. Once any errors have been eliminated, the program is fed into the machine and it begins production.

Open loop and closed loop machine systems

"The manipulation of a material on a CNC Machine is determined by either an open looped or closed loop system. An open loop system runs in one direction until the completion of the process while a closed loop system has the ability to accept feedback and make corrections of any possible errors, which could be speed of the feed or positioning of the material.

"An open loop control system is simple whose accuracy depends on how it is calibrated. Material is fed into the system and a completed part is returned. There aren't any in-process corrections, but the calibration has to be meticulously and carefully completed to avoid human errors. A good example of an open loop system is a washing machine where the clothes are put in the machine and removed when fully washed. The machine does not stop to correct itself or determine if the clothes are sufficiently clean.

"A closed loop system is dependent on the controller and is more complex and intricate than an open loop system. An open loop system has a controller process while a closed loop system contains an amplifier, controller, and receives feedback during the process. This can be seen in a heating system in a house where the heater activates when a set temperature is not present and deactivates or adjusts when there is enough heat. Since there is constant monitoring of the process, a closed loop system operates slower and carefully but is easy to calibrate since the system takes most of the responsibility.

"CNC equipment operates by referencing multiple axis points to remove material from the workpiece. The number of axis can vary and includes 3, 4, or 5 axes. With the basic three axes points, the material remains in the same position while being worked by the machine, which moves along an XYZ plane. The four axes points operate exactly like the three axes method with the addition of a fourth operation that may include cutting a hole or making a special cut. The five axes points method is more complicated than either of the other two. It manipulates five sides of the material and is used on highly technical complex components.

The CNC manufacturing process

"The CNC process is different from the traditional additive processes since it is a subtractive process where layers of material are removed to create custom shapes. Additive processes add layers. CNC is fully automated manufacturing with high reliability and precision machining.

"The key to the success of CNC manufacturing is the initial programming. The software must be coded with the proper instructions keeping the machine within the limitations of its parameters. The thinking of CNC equipment is derived from the person who creates its instructions in CAD, computer aided design, a basic engineering software. It is important that care be given to the development of the programmed instructions to avoid errors and loss of production time."

Die Casting vs. Machining

What are the differences between die casting and cnc machining?

According to DieCasting.com:

"There are a number of effective processes for making metal parts, but two of the most popular for industrial purposes are die casting and machining. But how do you know when to die cast and when machining is called for? Here are some of the basic reasons why you might choose die casting or machining and how the two processes can work together.

How Die Casting Works

"In die casting, your metal material, often an alloy of metals such aluminum, copper or zinc, is melted and injected into a steel die, or mold, in the shape of the part you wish to make. Once the metal fills the die, you cool it down so that the metal hardens in the desired shape, after which you remove it. You can then finish the part and do any necessary assembly.

How CNC Machining Works

"The CNC in CNC machining stands for computer numerical control, and it is a way to maximize the efficiency of machining through automating much of the process. Think of machining like sculpting with metal. We program the CNC robot which then cuts away at the metal until what is left is the desired part.

Die Casting or Machining?

"So, which should you use? It’s important to note that die casting and machining can often work together to optimize the effectiveness of your product line.

"You can use machining on a die casting part to create tighter tolerances or create features on the part that cannot be die cast, and you can even use machining to make the die itself that will be used for the die casting process.

"One advantage of using CNC machining is that it is better for low volume parts since no tooling cost is required. Die casting is the preferred option if you’re looking for a high volume of consistent, reliable parts.

"On the other hand, if your part has a lot of surface detail, you may prefer to use die casting. Surface details can be made right into the die so that your part comes complete with the surface details included, rather than having to machine them later during the finishing process.

"Another consideration when it comes to CNC machining vs. die casting is waste. With die casting, you use almost all the metal involved for the part, with little leftover scrap. On the other hand, there is a lot of scrap metal left lying around after you machine a part. Now, you can recycle that metal of course, but if you are machining parts or working with a company that is machining parts, you want to be sure that there is a recycling mechanism in place.

"If you’re looking to mass produce a high volume of durable, consistent parts affordably, die casting in aluminum or a related alloy is probably the way to go. If you have a smaller run of more complex parts, or you have particularly large or oddly shaped parts, CNC machining may be more effective..."

What is Forging?

You have heard of forging, but what exactly is it?

According to Thomas Net:

"Forging, a metal shaping technique using compressive, localized forces, has been a staple metal fabrication technique since the time of the ancient Mesopotamians. Since its origins in the fertile crescent, forging has experienced significant changes, resulting in a more efficient, faster and more durable process. This is because today, forging is most commonly performed with the use of forging presses or hammering tools that are powered by electricity, hydraulics or compressed air.

Different Types of Forging and Their Advantages

"The pounding action of forging deforms and shapes the metal, which results in unbroken grain flow. This causes the metal to retain its strength. Ancillary effects of this unique grain flow include the elimination of defects, inclusions, and porosity in the product. Another advantage of forging is the relatively low costs associated with moderate and long production runs. Once the forging tools have been created, products can be manufactured at relatively high speeds with minimal downtime.

Hot Forging

"There are two main types of forging -- hot and cold. Hot forging requires the metal to be heated above its recrystallization temperature. This can mean heating metals up to 2,300 degrees Fahrenheit. The main benefit of hot forging is the decrease in energy required to form the metal properly. This is because excessive heat decreases yield strength and improves ductility. Hot forged products also benefit from the elimination of chemical inconsistencies.

"Need a hot forging company? Thomas' Supplier Discovery has a vetted list of Hot Forging Companies in the U.S. and Canada.

Cold Forging

"Cold forging typically refers to forging a metal at room temperature, though any temperature below recrystallization is possible. Many metals, such as steel high in carbon, are simply too strong for cold forging. Despite this hindrance, cold forging does edge out its warmer equivalent when it comes to standards of dimensional control, product uniformity, surface finish, and contamination. Cold forging encompasses numerous forging techniques, including bending, extruding, cold drawing and cold heading. However, this increased versatility comes at a cost, because cold forging requires more powerful equipment and may call for the use of intermediate anneals.

"Need a cold forging company? Thomas' Supplier Discovery has a vetted list of Cold Forging Companies in the U.S. and Canada.

"For more detailed info on either of these processes please read our Full Guide to Hot Forging and Cold Forging.

Forging Process Categories

"Beyond basic hot and cold forging, many specific processes exist. This broad range of processes can be grouped into three primary umbrella groups:

"Draw forming decreases the width of the product and increases length.

"Upset forging increases the width of the products and decreases length.

"Compression forming provides forging flow in multiple or customized directions.

"These three categories entail many different specific types of forging:

Open Die Forging Process

"When flat dies that have no precut profiles engage in forging, the process is called open die forging (or smith forging). The open design allows the metal to flow everywhere except where it touches the die. To achieve maximum results, correct movement of the workpiece, which should be over 200,000 lbs. in weight and 80 feet long, is essential. It is useful for short-run art smithing or for shaping ingots prior to secondary shaping measures.

Closed Die Forging Process

"Closed die forging, sometimes called impression die forging, employs the use of molds. These molds are attached to an anvil while a hammer forces molten metal to flow into the cavities of the die. Multiple strikes and/or die cavities are often used when forging complex geometries. High initial tooling costs make closed die forging expensive for short-run operations, but the forging process becomes cost-effective as parts produced increases. Closed die forging also provides exceptional strength over alternative methods. Common applications of closed die forging include the production of automobile components and hardware tools.

Press Forging

"In press forging, the main forming factor is compression. The metal sits on a stationary die while a compression die applies continuous pressure, achieving the desired shape. The metal's contact time with the dies is considerably longer than other types of forging, but the forging process benefits from being able to simultaneously deform the entire product, as opposed to a localized section. Another benefit of press forging is the ability of the manufacturer to monitor and control the specific compression rate. Applications of press forging are numerous, as there are relatively no limits to the size of product that can be created. Press forging can be hot or cold forged.

Roll Forging Process

"Roll forging is the process of increasing rods or wires in length. The manufacturer places heated metal bars between two cylindrical rolls, which rotate and apply progressive pressure to shape the metal. Benefits of roll forging include the elimination of flashing and a superior grain structure."

How CNC is Used in the Aerospace Industry

CNC Machining has become more important to the Aerospace industry.

According to CNC.com:

"The aerospace industry encompasses all types of air traffic, from massive Boeing 747 jets that carry hundreds of passengers to spacecraft rockets designed to travel to the International Space Station, the moon, and even Mars for exploration purposes. Aerospace technology is made with some of the most incredible precision imaginable. As such, computer numerical control (CNC) fits quite well into this field where such amazing pieces of transportation are developed.

CNC in Aviation

"Aircraft carriers, from two-person private jets to commercial airplanes that carry a few hundred passengers around the globe, must be constructed with the utmost precision. This precision includes all facets of production, from the engine of the aircraft to the outer body of the jet. A CNC machine can play a critical role in quickly and precisely manufacturing specific tools that aid in the operations of each plane component. For example, in order for a plane’s engine to maintain an 8-hour flight, it must be designed to properly process and utilize the fuel inside it. A barely visible piece within the engine may be created with a CNC machine. The same may be said for the plane’s cockpit, which likely includes an intricate computer system to ensure the plane reaches its intended destination. In addition to these inner workings of a jet, the outside design like a plane’s wing could be modified with a CNC machine with extreme precision so that the wing functions through the air properly and efficiently.

CNC in Space Exploration & Travel

"When you think of space exploration and travel, the names NASA or SpaceX probably come to mind right away. These organizations have designed some of the most powerful rockets in the world that can traverse millions of miles around the solar system. CNC machining processes have been used to manufacture necessary components of all spacecraft types, from the inner workings to the body design. Spacecraft are designed to maintain themselves in outer space for months – or even years. With this long-term maintenance in mind, they must be developed with incredible precision and accuracy. From the computer system inside a rocket ship to the engine made for extreme durability, these transporters require the utmost attention to detail when on the assembly line. Safety is also a major factor at play, in addition to storage equipment for astronauts who take lengthy missions to space.

Industrial CNC Manufacturing

"Due to the high-powered nature of airplanes and spacecraft, industrial CNC manufacturing processes are certainly much more common than private, homemade attempts at CNC machining. As such, there is a great deal of expense involved in designing parts for the most powerful forms of transportation we enjoy today. That is why only the most wealthy companies and organizations in the marketplace can afford the luxury of automation when it comes to developing aerospace machines."

Types of Forging Processes

New to forging? Here is a breakdown of types of forging processes.

According to Forging.org:

Impression Die Forging

"Impression die forging pounds or presses metal between two dies (called tooling) that contain a precut profile of the desired part. Parts from a few ounces to 60,000 lbs. can be made using this process. Some of the smaller parts are actually forged cold.

PROCESS OPERATIONS

Graphical depiction of process steps.

"Still Graphic

"Animated Sequence

"Video

"Process Capabilities

"Commonly referred to as closed-die forging, impression-die forging of steel, aluminum, titanium and other alloys can produce an almost limitless variety of 3-D shapes that range in weight from mere ounces up to more than 25 tons. Impression-die forgings are routinely produced on hydraulic presses, mechanical presses and hammers, with capacities up to 50,000 tons, 20,000 tons and 50,000 lbs. respectively.

"As the name implies, two or more dies containing impressions of the part shape are brought together as forging stock undergoes plastic deformation. Because metal flow is restricted by the die contours, this process can yield more complex shapes and closer tolerances than open-die forging processes. Additional flexibility in forming both symmetrical and non- symmetrical shapes comes from various preforming operations (sometimes bending) prior to forging in finisher dies.

"Part geometry's range from some of the easiest to forge simple spherical shapes, block-like rectangular solids, and disc-like configurations to the most intricate components with thin and long sections that incorporate thin webs and relatively high vertical projections like ribs and bosses. Although many parts are generally symmetrical, others incorporate all sorts of design elements (flanges, protrusions, holes, cavities, pockets, etc.) that combine to make the forging very non-symmetrical. In addition, parts can be bent or curved in one or several planes, whether they are basically longitudinal, equidimensional or flat.

"Most engineering metals and alloys can be forged via conventional impression-die processes, among them: carbon and alloy steels, tool steels, and stainless, aluminum and copper alloys, and certain titanium alloys. Strain-rate and temperature-sensitive materials (magnesium, highly alloyed nickel-based superalloys, refractory alloys and some titanium alloys) may require more sophisticated forging processes and/or special equipment for forging in impression dies.

Cold Forging

"Most forging is done as hot work, at temperatures up to 2300 degrees F, however, a variation of impression die forging is cold forging. Cold forging encompasses many processes -- bending, cold drawing, cold heading, coining, extrusions and more, to yield a diverse range of part shapes. The temperature of metals being cold forged may range from room temperature to several hundred degrees.

Process Operations

"Graphical depiction of process steps.

Process Capabilities

"Cold forging encompasses many processes bending, cold drawing, cold heading, coining, extrusion, punching, thread rolling and more to yield a diverse range of part shapes. These include various shaft-like components, cup-shaped geometry's, hollow parts with stems and shafts, all kinds of upset (headed) and bent configurations, as well as combinations.

"Most recently, parts with radial flow like round configurations with center flanges, rectangular parts, and non-axisymmetric parts with 3- and 6-fold symmetry have been produced by warm extrusion. With cold forging of steel rod, wire, or bar, shaft-like parts with 3-plane bends and headed design features are not uncommon.

"Typical parts are most cost-effective in the range of 10 lbs. or less; symmetrical parts up to 7 lbs. readily lend themselves to automated processing. Material options range form lower-alloy and carbon steels to 300 and 400 series stainless, selected aluminum alloys, brass and bronze.

"There are times when warm forging practices are selected over cold forging especially for higher carbon grades of steel or where in-process anneals can be eliminated.

"Often chosen for integral design features such as built-in flanges and bosses, cold forgings are frequently used in automotive steering and suspension parts, antilock-braking systems, hardware, defense components, and other applications where high strength, close tolerances and volume production make them an economical choice.

"In the process, a chemically lubricated bar slug is forced into a closed die under extreme pressure. The unheated metal thus flows into the desired shape. As shown, forward extrusion involves steel flow in the direction of the ram force. It is used when the diameter of the bar is to be decreased and the length increased. Backward extrusion, where the metal flows opposite to the ram force, generates hollow parts. In upsetting, the metal flows at right angles to the ram force, increasing diameter and reducing length.

Open Die Forging

"Open die forging is performed between flat dies with no precut profiles is the dies. Movement of the work piece is the key to this method. Larger parts over 200,000 lbs. and 80 feet in length can be hammered or pressed into shape this way.

PROCESS OPERATIONS

"Graphical depiction of process steps.

"Still Graphic

"Animated Sequence

"Video

"Process Capabilities

"Open-die forging can produce forgings from a few pounds up to more than 150 tons. Called open-die because the metal is not confined laterally by impression dies during forging, this process progressively works the starting stock into the desired shape, most commonly between flat-faced dies. In practice, open-die forging comprises many process variations, permitting an extremely broad range of shapes and sizes to be produced. In fact, when design criteria dictate optimum structural integrity for a huge metal component, the sheer size capability of open-die forging makes it the clear process choice over non-forging alternatives. At the high end of the size range, open-die forgings are limited only by the size of the starting stock, namely, the largest ingot that can be cast.

"Practically all forgeable ferrous and non-ferrous alloys can be open-die forged, including some exotic materials like age-hardening superalloys and corrosion-resistant refractory alloys.

"Open-die shape capability is indeed wide in latitude. In addition to round, square, rectangular, hexagonal bars and other basic shapes, open-die processes can produce:

"Step shafts solid shafts (spindles or rotors) whose diameter increases or decreases (steps down) at multiple locations along the longitudinal axis.

Hollows cylindrical in shape, usually with length much greater than the diameter of the part. Length, wall thickness, ID and OD can be varied as needed.

Ring-like parts can resemble washers or approach hollow cylinders in shape, depending on the height/wall thickness ratio.

Contour-formed metal shells like pressure vessels, which may incorporate extruded nozzles and other design features.

Not unlike successive forging operations in a sequence of dies, multiple open-die forging operations can be combined to produce the required shape. At the same time, these forging methods can be tailored to attain the proper amount of total deformation and optimum grain-flow structure, thereby maximizing property enhancement and ultimate performance for a particular application. Forging an integral gear blank and hub, for example, may entail multiple drawing or solid forging operations, then upsetting. Similarly, blanks for rings may be prepared by upsetting an ingot, then piercing the center, prior to forging the ring.

Seamless Rolled Ring Forging

"Seamless rolled ring forging is typically performed by punching a hole in a thick, round piece of metal (creating a donut shape), and then rolling and squeezing (or in some cases, pounding) the donut into a thin ring. Ring diameters can be anywhere from a few inches to 30 feet.

PROCESS OPERATIONS

"Graphical depiction of process steps.

"Still Graphic

"Animated Sequence

"Video

"Process Capabilities

"Rings forged by the seamless ring rolling process can weigh < 1 lb up to 350,000 lbs., while O.D.’s range from just a few inches up to 30-ft. in diameter. Performance-wise, there is no equal for forged, circular-cross-section rings used in energy generation, mining, aerospace, off-highway equipment and other critical applications. "Seamless ring configurations can be flat (like a washer), or feature higher vertical walls (approximating a hollow cylindrical section). Heights of rolled rings range from less than an inch up to more than 9 ft. Depending on the equipment utilized, wall-thickness/height ratios of rings typically range from 1:16 up to 16:1, although greater proportions have been achieved with special processing. In fact, seamless tubes up to 48-in. diameter and over 20-ft long are extruded on 20 to 30,000-ton forging presses. "Even though basic shapes with rectangular cross-sections are the norm, rings featuring complex, functional cross- sections can be forged to meet virtually any design requirements. Aptly named, these contoured rolled rings can be produced in thousands of different shapes with contours on the inside and/or outside diameters. A key advantage to contoured rings is a significant reduction in machining operations. Not surprisingly, custom-contoured rings can result in cost-saving part consolidations. Compared to flat-faced seamless rolled rings, maximum dimensions (face heights and O.D.’s) of contoured rolled rings are somewhat lower, but are still very impressive in size. "High tangential strength and ductility make forged rings well-suited for torque- and pressure-resistant components, such as gears, engine bearings for aircraft, wheel bearings, couplings, rotor spacers, sealed discs and cases, flanges, pressure vessels and valve bodies. Materials include not only carbon and alloy steels, but also non-ferrous alloys of aluminum, copper and titanium, as well as nickel-base alloys." Original Source

The Role of CNC Machines in the Making of Prototypes

Curious about the role of CNC machines when it comes to making prototypes? Consider this.

According to Tech Zone 360:

“CNC machining is amazingly diverse and is used in a variety of modern industries. From aerospace to electronics to the military, CNC machining plays a significant part in manufacturing and development.

“The Covid-19 crisis hit the economy hard, but CNC machining kept many businesses afloat and prevented layoffs. The CNC industry is at the forefront of business innovation. It is used in all phases of the manufacturing process, but it has become especially useful in creating prototypes.

“Tom Kohm, President & CEO of Premier Equipment, explains, “Almost every product that is made from metal starts with a prototype that uses a combination of manual equipment and CNC machines. Many companies that have a brilliant idea or invention will either hire a manufacturing shop to produce a prototype or the company will purchase their own machine with a programmer to develop a prototype.”

“In the last couple years, the manufacturing industry has been under pressure to produce more, have goods cost less, and not eliminate workers. Global competition has placed businesses in a tough spot where they want to retain talent and meet customer expectations. That is where advanced manufacturing helps to meet both goals.

“Machines are no longer just the tool but the craftsperson itself. Devices can be tailored to work both on the physical side, such as consolidating tool measurement and the software side, where smarter machines can customize and monitor themselves. An advanced system can catch an error long before a human would have noticed it.

“Machines can also train the workforce on how best to use more advanced technology. In this way, instead of craftspeople being laid off, they can be retrained and learn new skills. This is all without the risk that manufacturing can bring. We eliminate the dangers of repetitive movement injuries, pathogen exposure, and industrial accidents.

“Increasingly businesses are turning to CNC factories to produce prototypes. There are several reasons for this decision.

“Automation – Machines can be left unattended for long periods. When you are trying to decrease the cost of a risky prototype, CNC machine shops are more cost-effective.

“Customization – When you are creating a prototype, you are often using parts that have never been used before. CNC manufacturing allows you to customize features any way you’d like them. It is easy to make the parts bigger, smaller, rounder, or more angular. You have better control over your product.

“Precision – The machines are going to craft the prototype exactly the way the engineers envisioned it. It is going from the blueprint to its physical form based on the same computer files and 3-D models used to design it. This also allows for high repeatability if more prototypes are needed.

“Flexibility – In an uncertain world, needs can change quickly. Machine formation makes it extremely easy to make design changes without scraping the entire product and starting again. The design is already saved. You can make your changes safely and efficiently.

“We live in a time when it feels like manufacturers are expected to do everything. They need to turn out prototypes fast, at a reasonable price, and that are exceptionally reliable. CNC manufacturing allows factories to have it all in one place.”

WHY CHOOSE FORGINGS

You may be considering forgings for your next project. Here is why you should use them.

According to Forge Resource Group:

WHAT IS FORGING?

"Forging is the process of heating, deforming and finishing a piece of metal. Forgings are made by forcing materials into customized shapes either by the force of a falling ram upon an anvil or by a die press enclosing a piece of metal and squeeze-forming the part. Due to the realigning of the grains of metal when heated and deformed, forgings can withstand extreme pressure and maintain structural integrity under stress. Once produced, forgings have a broad range of uses across a variety of industries ranging from heavy trucks, medical supplies, automotive parts, to aerospace.

"The forging process creates parts that are stronger than those manufactured by any other metalworking process. Forging takes advantage of the metal’s natural grain flow, shaping the grain flow to conform to the contours of each part’s unique geometry. This grain flow contouring is lost when cutting through the grain by machining it and is also lost when casting parts. Forging offers a single piece versus a welded unit, as the weld quality can be hard to replicate without additional inspection.

"Forgings can be nearly any shape, which reduces the need for joining multiple pieces. Reducing the joint can improve the overall strength of the unit as the forging does not need to be welded or otherwise fastened together.

HOW DO FORGINGS COMPARE TO CASTINGS?

"Forgings are stronger. Castings do not have strengthening benefits yielded by hot and cold forgings. Forging surpasses casting in predictable strength properties and produces superior simultaneously more ductile and resistant pieces with uniform quality assured across the production run.

"Forging refines defects from cast ingots or continuous cast bar. A casting has neither grain flow nor directional strength and the casting process cannot prevent formation of certain metallurgical defects. Pre-working forge stock produces a grain flow oriented in directions requiring maximum strength. Dendritic structures, alloy segregations, and similar imperfections are also refined in forging.

"Forgings are consistently more reliable and often less costly over time compared to castings. Casting defects occur in a variety of forms. Because hot working refines grain patterns and imparts high strength, ductility, and resistance to each forged piece they are also more durable. Also, they are manufactured without the added costs for tighter process controls and inspection that are required for castings.

"Forgings also offer better response to heat treatment. Castings require close control of melting and cooling processes because alloy segregation may occur. This results in a non-uniform heat treatment response that can affect the straightness of finished parts. Forgings respond more predictably to heat treatment and offer better dimensional stability.

"Production of forgings allows for flexible, cost-effective adaption to market demand. Some castings, such as special performance castings, require expensive materials and process controls, and longer lead times. Open-die and ring rolling are examples of forging processes that adapt to various production run lengths and enable shortened lead times.

HOW DO FORGINGS COMPARE TO WELDMENTS/FABRICATIONS?

"Forgings offer production economies and material savings. Welded fabrications are more costly in high volume production runs. In fact, fabricated parts are a traditional source of forging conversions as production volume increases. Initial tooling costs for forging can be absorbed by production volume and material savings. Forgings’ production economics lower labor costs, scrap and rework reductions through reduced inspection costs.

"Forgings are stronger. Welded structures are not generally free of porosity. Any strength benefit gained from welding or fastening standard rolled products can be lost by poor welding or joining practice. The grain orientation achieved in forging makes stronger parts.

"Forgings also offer cost-effective designs. A multiple-component welded assembly cannot match the cost-savings gained from a properly designed, one-piece forging. Such part consolidations can result in considerable cost savings. In addition, weldments require costly inspection procedures, especially for highly stressed components. Forgings do not.

"Forgings offer more consistent, better metallurgical properties. Selective heating and non-uniform cooling that occur in welding can yield undesirable metallurgical properties such as inconsistent grain structure. When in use, a welded seam may act as a notch that can contribute to part failure. Forgings have no internal voids that might cause unexpected failure under stress or impact.

"Forgings offer simplified production. Welding and mechanical fastening require careful selection of joining materials, fastening types and sizes, and close monitoring of tightening practices both of which increase production costs. Forging simplifies production and ensures better quality and consistency.

HOW DO FORGINGS COMPARE TO MACHINED BAR/PLATE?

"Forgings offer a broader size range of desired material grades. Sizes and shapes of products made from steel bar and plate are limited to the dimensions in which these materials are supplied. Often, forging may be the only metalworking process available with certain grades in desired sizes. Forgings can be economically produced in a wide range of sizes, from parts whose largest dimension is less than 1 inch, to parts weighing more than 450,000 lbs.

"Forgings are grain oriented to shape for greater strength. Machined bar and plate may be more susceptible to fatigue and stress corrosion because machining cuts into material grain patterns. In most cases, forging yields a grain structure oriented to the parts’ external contours, resulting in optimum strength, ductility and resistance to impact and fatigue.

"Forgings make better, more economic use of materials. Flame cutting plate is a wasteful process, one of several fabricating steps that consumes more material than needed to make such parts as rings or hubs. Even more material is lost in subsequent machining.

"Forgings yield lower scrap and increase efficiency of production. Forgings, especially near-net shapes pieces, make better use of material and generate little scrap. In high-volume production runs, forgings have a decisive cost advantage.

"Forgings require fewer secondary operations. As supplied, some grades of bar and plate require additional operations such as turning, grinding, and polishing to remove surface irregularities and achieve desired finish, dimensional accuracy, machinability, and strength. Often, forgings can be put into service without expensive secondary operations..."

7 Best Prototyping Methods And Techniques For Your Next Manufacturing Project

There are 7 methods that are best when it comes to prototyping. Consider this.

According to IMC Grupo:

"Every successful product on the market starts with a brilliant idea. But showcasing new design concepts still in development always comes with a specific price, often not cheap. It would help if you produced a prototype to display the new product to lure investors or impress possible buyers. Nowadays, prototyping is far less expensive than before. There’s a wide array of approaches to choose from, depending on your developing product.

"So what exactly is prototyping? It is a series of technological practices that enable the manufacturing of 3D items from a wide range of raw materials. The basis of the object is a 3D computer-aided design model, colloquially known as CAD.

"The purpose of rapid prototyping is to put together an early version of the product promptly. Maybe the most popular technique in recent years is 3D printing. However, as technology advances, new methods have emerged, and now you can allow yourself to choose, depending on what your priorities are (functionality, aesthetics, endurance). Here are the seven best prototyping methods and techniques for your next manufacturing project.

Sheet Metal Prototyping

"This prototyping method encompasses hardware specifically intended to curve, cut, and penetrate through sheet metal. If your product idea has components made of sheet metal, this would be your preferred technique.

"The manipulation of the sheet metal’s form leaves its structure intact so that the prototype will maintain its strength after the procedure. Lots of different kinds of metals can be processed with this method.

"Sheet metal prototyping is prevalent in making components for automobiles and other vehicles, appliances, and kitchen and office apparatuses. The process is speedy, reconfigurable, and incredibly reliable.

Injection Molding

"Disregarding some significant discrepancies, injection molding is relatively the same as vacuum casting. In the beginning, the mold is filled with molten material with the help of a reciprocating bolt. In most cases, the mold used in the processes is made for aluminum or steel.

"Before you can construct elements with this method, the mold needs to be created with prototype tooling. The mold can be made by different means – rapid tooling, 3D printing, or hand tooling. It is also quite expensive. So, only choose this technique if you are planning to manufacture parts; in large numbers.

Aluminum And Plastic Extrusion

"The process in which softened material is forced through a die (shaped opening) and then flows out in the desired shape is called extrusion. The critical component in the process is that the die is quite an expensive part, and it’s constructed with CNC machining. So, extrusion is a logical choice if needed to manufacture large amounts of parts/products.

"Generally, extrusion is either aluminum or plastic. And while you already know enough about aluminum extrusion as it’s one of the most coveted manufacturing processes worldwide, there’s very little coverage of its plastic counterpart.

"Polystyrene, Nylon, and Polypropylene are some of the plastics that are suitable for extrusion when heated. Alloys containing aluminum are very pliable, so they are go-to extrusion materials.

CNC Machining

"CNC machining is the leader among manufacturing techniques. Milling machines controlled by specialized computers and lathes can carve out an infinity of curves, holes, or channels on strong materials like metal and plastic. No heating or melting means a more substantial structure, which gives the prototype longevity.

"The technique is excellent because it applies to a vast number of materials, metals, and plastics. The evolution of CNC machining has come a long way and now uses impressive milling machines with multiple axes. They score high in reliability, accuracy, and efficiency. Oh, and they are very fast! A prototype can be manufactured in only minutes (although more complex objects may take hours).

Pressure Die Casting

"Pressure die casting is much quicker and less expensive than machining in regards to prototyping of metal components. In many ways, it is reasonably similar to injection molding. The difference is the utilization of molten metal, unlike injection molding, where elastomers are used. Magnesium, aluminum, zinc, and steel are among the base metals suitable for this method of prototyping.

"Regarding the volume of production desired, this method is considered feasible even if you only need to manufacture a handful of prototypes. It’s efficient in creating big as well as mid-sized parts. The surface finish on the prototype is impeccable, and the precision is admirable. In case there are faults in the components after the pressure-die casting, CNC machining can smooth out any deficiencies.

Surface Finishing

"Most specialized prototyping services pay a tremendous amount of attention to detail. That’s why they provide surface finishing as a service to enhance the visual appeal. Several finishing methods are accessible, as well as a wide range of materials.

"The visual appeal of a prototype that will be used for exhibiting must be one of the priorities. You can choose from different options ranging from basic painting to more intricate techniques like anodizing or powder coating. But it’s not just the looks. A good finish improves strength, corrosion resistance, conductivity, and other metallurgical properties.

3D Printing

"Last on our list, but definitely not least, 3D printing is one of the most flexible methods that creates the most extraordinary and intricate designs. 3D printers are everywhere these days. The technology has gotten a lot cheaper and more accessible and can work wonders. It usually uses plastics and resin as input materials.

"The beauty of 3D printing is the extraordinary accuracy and control that it provides to the user. However, printing one layer onto another can take up some time, so if you need a significant production volume, it is most likely not the best option.

Final Words

"Being in control of your product development is crucial in order to place your finished product on the market as soon as possible. If you are the first one there, It’s highly likely that the timing will set you apart from the competition. Rapid prototyping is a technology that can make that difference. So, plan carefully and always choose the technique most suitable for your next manufacturing project."