How CNC machining is enhancing manufacturing

CNC Machining has had an impact on manufacturing.

According to Easier.com:

"Whether your manufacturing business has been on the market for a while or you are new to the game, learning about technologies to improve your business and production operations will ensure a successful business future. So, there’s a good chance you’ve already heard about CNC machining.

"Computer Numerical Control (CNC) machines have enabled small and mid-sized manufacturers to stay competitive against the big-name companies by providing the means to rapidly increase productivity via computerization and automation.

"Today, CNC machines are widespread. These machines are dominating the manufacturing world, allowing for a significant jump in productivity across the globe.

"Here’s how CNC is improving manufacturing by the day.

The Role of CNC Machines in Manufacturing

"CNC machining utilizes computers to regulate the entire manufacturing process. Essentially, it takes computer automation to an entirely new degree. Manufacturers are able to input the specific details of what should be done and leave the CNC machines to carry out the rest of the work with little to no supervision.

"Mills, lathes, drills, and many other devices will all remain working as long as required, doing whatever is needed with little human input.

"Because CNC parts have exceptional accuracy and material properties, CNC machining is currently one of the few manufacturing processes suitable for creating parts for critical space applications. Not to mention the variety of surface treatments you can apply to the parts after machining.

"With the development of CNC technology, we have seen a plethora of advancements applied far beyond the CNC industry, e.g., improved engine communications and simplified programming language. As it continues to advance, we can rest assured that plenty of more exciting improvements in CNC are yet to come.

How Do These Machines Work?

"CNC machines comprise of computers where the program is fed for cutting of the metal of the job as required. All the cutting processes and final dimensions are fed into the computer via the program. That’s how the computer knows what to be done, carrying out all the cutting processes. So, basically, a CNC machine works like a robot - it is fed via the program and follows your instructions.

"Some common machine tools that run on the CNC include lathe, drilling machine, milling machines, etc. The key purpose of these CNC machines is to eliminate some of the metal to give it a proper shape like round, rectangular, and so on.

"The role of an operator in CNC machines is greatly reduced. The operator only has to feed the program of instructions on the computer and then load the necessary tools into the machine. After that, the rest is performed automatically by the computer itself.

6 Ways CNC Machining is Improving Manufacturing

Ultra Convenience

"With CNC machines, there’s a great reduction in manual work. This saves time and makes production operations more efficient and smooth. Automated operations are usually faster compared to manual human input. Digitized manufacturing further helps in reducing human errors and is able to operate whenever required.

"For those wondering if CNC machining will completely replace human-led operations, as intimidating as it may sound, CNC machines are not here to replace humans, but to empower us to make our daily tasks more pleasant.

Fewer processes

"When it comes to CNC machine monitoring, computers and software are the two main parts. CAD model preprograms the sought projects and uploads data to the device. Another great advantage of this technology is that it has the ability to perform almost every producing step by itself. This eliminates the call for additional machines and tools or even manual work.

Sustainability

"CNC machining tends to drive sustainability in a number of ways. The technology does not demand any additional materials, meaning it doesn’t leave any waste. It also has little to no chances of making errors. This prevents tossing parts and materials away and wasting crucial production time.

"Moreover, CNC machining does not require any additional parts, such as separate sanders or drills, as it has pretty much everything embedded in the body.

Prototype Machining

"In the world of manufacturing, prototyping is extremely crucial as it helps in avoiding errors in the production process later on. It also helps to understand the product better. That said, many manufacturers skip the prototyping bit or do not invest sufficient time in it due to the fact that it is costly and time-consuming.

"Thanks to CNC machining, prototyping is now more affordable than ever. It’s also easier to attain. Manufacturers are able to craft mock-ups and get a clear idea of what the next step will be in the process. The CNC machining technology navigates through a variety of manufacturing processes and enables developing more complex designs.

Affordable

"Besides being compact in size, the price tag on CNC machines is also decreasing, meaning people can now invest in their own machinery and carry out critical production work on-site, instead of having to outsource costly work overseas.

More Employment Opportunities

"It may seem like using a machine to perform the majority of operations would replace rather than create job opportunities, but it’s actually the opposite.

"Although there’s no need to hire workers to carry out the job the machine is doing (e.g., drilling, cutting, boring), new job roles will emerge requiring more and more people to maintain the machines, supervise production, examine the output quality, sales, installation, troubleshooting, and so on.

Wrapping Up

"Manufacturers need to start thinking of CNC machining and its future if they aren’t already. Rapid prototyping and other services in the CNC industry, are already being automated. Businesses that don’t opt for automation are basically being left behind.

"There are a variety of reasons to automate, with some being to stay super competitive and cut a big chunk of manufacturing expenses.

"Staying competitive indicates delivering higher-quality products at a larger scale to consumers faster than your competitors can. Luckily, CNC machining automation can help reduce waste, which, in turn, helps businesses cut expenses.

"While the changes to an automated industry may cost a fortune, the pros are endless, so much so that businesses will soon be left behind if they don’t take this path."

What Green Businesses Can Expect From CNC Machining In The Future

For businesses looking to reduce their carbon footprint and in other ways be more green, consider CNC Machining.

According to Blue and Green Tomorrow:

"Green businesses are looking for more sustainable manufacturing solutions. There are a number of ways that manufacturing can be changed to produce a lower carbon footprint.

"One of the changes people are considering is CNC machining. This is a good way to lower emissions and help make products more sustainably.

"One of the biggest reasons that CNC machining is greener is that it can be done electronically. Customers can send electronic files to the factories, which means that they don’t have to travel to the site. This is an underrecognized greener alternative, because it reduces carbon emissions from driving.

CNC Machining is the Key to Sustainability in 2020

"Just like everything else that surrounds us, modern manufacturing and production are rapidly changing. One particular item driving this growth is the CNC machine. First introduced in the 1940s, these Computer Numerical Control (CNC) machines changed the manufacturing game forever. They make it possible to scale any given manufacturing process without losing quality and accuracy along the way. Over time, with the widespread use of computers, CNC machining has become an essential part of the manufacturing sector.

"One of the many benefits of CNC machines is improved efficiency. Smart green companies are using it to lower their carbon footprint to a significant degree. Science Direct published the summary of a study from Finland, which identified various ways that CNC machining lowers emissions. One of the biggest reasons CNC machining lowers emissions is by reducing transportation, but it also reduces material waste and machining time as well. This means that there is less of a carbon footprint with running machines longer than necessary or removing large amounts of waste.

"Since technology has come a long way, nowadays, CNC machines rely on Computer-Aided Design (CAD) files to create prototype parts. With every part of the process controlled by a computer, these parts come as extraordinarily technical and highly automated products. To achieve such precise level of control, old industrial equipment such as routers, drills, and lathes are driven by unique computer programs, which make CNC machining stand out. As it simplifies the whole manufacturing process, it is widely used in many different industries.

"There have been a number of changes with CNC products in recent years. There are a lot of changes in the CNC industry, which green living experts should be aware of.

Cheaper CNC Services

"CNC machining is getting cheaper and more affordable than ever. Altogether with the machines, it’s becoming more economical to commission a company that offers CNC services to do any machining. Prototyping companies can buy these machines at a fraction of the cost they used to have. Furthermore, the barrier of entry into the CNC machining industry is lower than ever. Because of this, serious outsourcing companies now offer a diverse range of services, including prototype manufacturing and prototype machining.

Internet Of Things

"It’s nothing new that most of the planning and organization of our lives is done on devices. So the question here is, why can’t be the same done in factories? There are many changes, caused by the the Internet of Things (IoT). This new technology is providing automation in incredible ways. IoT facilitates communication between machines within a given network. This encourages collaboration, which leads to the development of a higher-quality product.

"Machines are also connected to computers or mobile devices, so some of these companies are offering their services online. CAD files can be transmitted electronically, which enables them to work on the project. This stuff is better yet in CNC machining, but you can also send designs for injection molding services and rapid machining.

Fear of Unemployment

"There are a lot of concerns about automation these days. One of the biggest concerns is that it will displace workers.

"At the same time, automation can help create new jobs too. Companies that offer CNC machining services will need maintenance, upgrades, and updates for their machinery. Technicians will always be around to troubleshoot and take care of CNC machines. Also, programmers with machine learning skills will be in higher demand as the software in these machines will have to be coded by such.

Smaller Devices

"Not that long ago, CNC machines were huge and pretty dangerous to work on. As the technology evolves, so has the manufacturing process of these machines. Nowadays, it’s pretty easy to find prototype molding machines that can fit in a single room or even less. CNC machines have become smaller and more compact. Since they can now interact with each other and work together, companies are going with many smaller portable devices instead of big, immobile machines.

"Take 3D printers as an example. Even though many people don’t consider them as part of the CNC machining family, they are and can fit in your room.

"Once the merger amongst IoT and CNC machining is done, machines will be able to work indefinitely. As companies that offer rapid machining can’t afford to have any downtime, engineers are tirelessly working to improve the reliability of the machines. As the demand for CNC-machinery-made products increases, so does the need for CNC machines that operate at optimum levels.

"As numerous companies turn to automated systems, coders and developers will have to make the control systems as intuitive as possible. This implies that they will need to simplify the user interface of the machinery and make them more user-friendly.

Product Quality Improvement

"As companies strive to produce the most excellent products possible, CNC machines will only get better with time. Competitive companies that offer CNC services are continuously working on tightening their tolerances and quality control systems. They are offering to produce orders of any quantity, using a wide range of materials selection, at affordable prices with the highest quality possible.

Better Tech Support And Further Investments

"With companies adopting different technologies of the modern era, the world of CNC machining is continuously changing for the better. CNC machinery companies extensively engage tech support representatives to improve their tech support offerings of the machines.

"Companies that haven’t invested in CNC machinery will experience hard times trying to catch up with their competition. As robots and machines work 24 hours a day, companies that adopted the CNC machining process could quickly decimate the market share of the companies that are still questioning whether to jump on the bandwagon.

The Future Is Now

"Services such as rapid prototyping in the industry are already fully automated, and companies that don’t embrace this automation risk being left behind. If you are into staying competitive on the market and cutting manufacturing costs, at least explore the idea of automating the process of manufacturing in your company. Even though the changes towards an automated industry do cost a lot of money, the upside of the whole switch is so vast that companies end up losing money if they don’t take the path of CNC machining.

CNC Machining Is A Green Alternative To Traditional Manufacturing

"There are many ways that companies can take greener initiatives. One way to lower emissions is by using CNC machining. With much more to come that we can’t even envision from today’s perspective, look ahead and make sure your company is staying competitive. The future is now!"

CNC Machining Is More Accessible Than You May Think

Some might think CNC machining is too complex to really get into, but it is more accessible than one might think.

According to Manufacturing.net:

"Despite the advances of 3D printing, CNC machining is the most cost-effective method of on-demand manufacturing, especially for metal parts. Let’s break down their costs.

"CNC machining is an established digital manufacturing process that produces high-accuracy parts with excellent physical properties directly from a CAD file. Although it’s been around since the early 50’s, recent technological advancements in digital supply chains have reduced the cost of CNC machining drastically and made it easily available to more professionals.

"3D printing or additive manufacturing is another digital manufacturing technology that can produce parts on-demand. Since 3D printing requires no tooling, start-up costs are low, making it particularly competitive for low volumes or one-off custom parts.

"The extensive mainstream media coverage on 3D printing may have lead to inflated expectations from this technology in applications where it is not the most suitable — especially for metal part production.

"In this article, we’ll take a closer look into the costs of CNC machining (machine, labor and material costs) and compare it to 3D printing through some back-of-the-envelope calculations and practical examples to gain a better understanding of the current state of these two technologies.

Machine Costs

"Overhead machine cost corresponds to approximately two thirds of the overall cost of both CNC machining and 3D printing. Generally, the machine rate (cost per hour) is calculated by dividing the cost of purchase by the total hours the machine is expected to operate (typically eight years for 5,000 hours per year).

"CNC machines come in different variations. Depending on their machine architecture and capabilities the typical machine per hour differs.

Mnet 195926 Cnc 1

"The typical rate of a 3-axis CNC milling machine (excluding the operator salary) is $40 per hour. To this, the machine operator salary should be added, which usually range at around $35 per hour. CNC turning is usually priced lower at $35 per hour, while the machine cost per hour of multi-axis CNC machining typically ranges between $75 and $120 or higher.

"On the other hand, the hourly rate of industrial 3D printers varies between $10-20 for industrial SLS or FDM machines to more than $100 per hour for metal SLM and DMLS 3D printing systems. To this, costs related to the risk of print failure should also be included; according to a study, risk-related costs can double the operating cost of 3D printing.

"This means that the total cost of owning and running a CNC machine is comparable to (or in the case of metal much lower than) that of an industrial 3D printer.

Material Costs

"The table below summarizes the price of stock metal alloys and plastic materials commonly used in CNC for a sheet with dimensions of 6'' x 6'' x 1'' (or approximately 150 x 150 x 25 mm).

Mnet 195927 Cnc 2

"The same volume of material corresponds to approximately $40 worth of Nylon 12 powder for SLS 3D printing — or 650 grams at $60 per kg — or $1300 worth of stainless steel powder for DMLS or SLM metal 3D printing — or 4.3 kg at $300 per kg.

"Of course, CNC machining, being a subtractive manufacturing technology, has considerable waste as material is removed from the original block. Also, parts designed for (especially metal) 3D printing should be topology optimized to reduce their weight, so they use as little material as possible.

"What is often overlooked is that 3D printing can also be wasteful: depending on the process, only 50-80 percent of the unused powder (in the case of SLS and DMLS/SLM) can be reused. The price one pays for this piles up fast, especially considering the cost of 3D printing materials.

"So, generally speaking, the cost of materials in 3D printing is considerably higher than in CNC.

Labor Costs

"The labor cost for the 3D printing machine operator are relatively low, as the process is mostly automated. Engineering and design costs for 3D printing are high, though, as the parts may require re-design and optimization. Also, considerable manual work is required for post processing and finishing a 3D printed part (cleaning, support removal, surface polishing).

"On the other hand, labor in CNC machining is primarily connected to start-up costs (CAM programming, process planning), but these are one-off costs and are eliminated for higher production volumes. Quoting traditionally demanded considerable resources from the machine shops, but this is not the case anymore. Let’s see why this is the case.

"CNC machining technology has not changed significantly during the past few years. Incremental improvements in machine design, tooling, consumables and CAM software lead to an optimization of the production cycles, improving quality and but not significantly affecting the cost of CNC machined parts.

"What has changed are the manufacturing supply chain networks surrounding the CNC machining process.

"For example, online manufacturing networks are becoming smarter and faster. A big step forwards was the automation of the quoting process for both clients and manufacturers. Using machine learning and artificial neural networks, the cost of manufacturing a part with CNC machining can be predicted (based on its geometry, material and other specifications) and an instant quote to the customer can be provided.

"A process that used to take a few hours of work from an engineer to complete (with considerable investment from the side of the manufacturer), now is almost instant, automated and free. This advancement alone has considerably reduced the cost of CNC.

"A Practical Example

"To illustrate the cost of modern CNC machining, I ran a small experiment. Using the test bracket of the image below as an example, I request quotes for different manufacturing processes, materials and quantities from the online network of manufacturing service providers of 3D Hubs. Since 3D Hubs operates at a global scale and provide automated pricing, this a good representation of the 'real-time' market price for manufacturing this particular geometry.

Mnet 195928 Cnc 3

"The table below summarizes the results of this short experiment, showing the cost of producing this part through CNC machining in aluminum and stainless steel, or through 3D printing in SLS Nylon or in PLA with FDM.

Mnet 195929 Cnc 4

"Notice that the difference of CNC machining the bracket out of aluminum versus 3D printing printing it out of nylon is relatively small even at low volumes (about $55 for a one-off part). CNC machining actually becomes more economical for quantities above 100 units.

"For the record, if you wanted to produce the same bracket through metal 3D printing with SLM, it would cost you $1,500 upwards for an one-off part.

"Why would you choose 3D printing then?

"Both CNC machining and 3D printing are exceptional tools with unique benefits that make each more suitable for different applications.

"For example, the cost of creating a single prototype of this bracket with FDM 3D printing was less than $8, while the cost of manufacturing it out of plastic (Delrin, ABS or Nylon) with CNC was about the same as aluminum (at around $100).

"Or when topology optimization for weight reduction is critical (for example, in aerospace applications) and traditional methods cannot produce the designed part geometry, then metal 3D printing with DMLS/SLM is still the best option available today.

"As a rule of thumb, parts with relatively simple geometries that can be manufactured with limited effort through a subtractive process should generally be CNC machined, especially when producing metal parts.

"The next table summarizes the most important use cases of 3D printing and CNC machining today:

Mnet 195930 Cnc 5

"Lately, there has been a lot of interest in the area of metal 3D printing and additive manufacturing. Even though the benefits of this technology for high-end applications are really exciting, the cost greatly outweighs the rewards for the majority of today’s manufacturing needs.

"Today, CNC machining is still the most accessible solution for on-demand manufacturing of custom parts, and this is not probably going to change in the near future.

"Of course, the new metal 3D printing systems (based on Binder Jetting and Material Extrusion technologies) that are due to be released this year may change this, but we will have to wait and see if they will have indeed a significant impact on the industry."

11 Tips For Growing Your CNC Machining Business

For small CNC machine shops looking to grow your business, here are some tips.

According to Thomasnet.com:

1. Develop Partnerships

"For many start-up machine shop owners, the early days can be an uncertain time in which numerous concerns, such as volume expectations, client lists, or even floor plans, have yet to be resolved. In these circumstances, existing friendships and business connections can be valuable assets.

"Whether having friends steer clients in your direction, enter into partnerships, or simply provide advice on business practices, relying on your current connections can give you a useful leg-up. Many also build their network through industry events and webinars.

2. Target Your Segment of the Marketplace

"It is generally a good practice to focus on the specific types of purchasers that will buy your products at the best volume rate. For example, if your shop specializes in producing gear shafts with a diameter under five inches, try to establish relationships with companies that purchase this product at a rate favorable to your production cycle and turnover.

"Targeting your market niche will help you make the best use of your specialty. A good example of a company who targets a niche market is Fanuc Spares. They focus only on this specific manufacturer and specialize only in replacement parts. This proved to be a very successful model for what may seem like a limited market. Another marketing method is leveraging emerging technologies such as the internet, videos and social networking which can help improve your shop's visibility online and reach more buyers. Share videos touring your shop floor — you can have a video created by Thomas to help prospects get a look at your operation.

3. Don’t Rush to Expand

"Purchasing machines that are not yet cost-efficient or enlarging facilities without the staff needed to maintain them can slowdown business growth and actually hinder long-term expansion. In many cases, it may be better to concentrate on making steady gains rather than giant leaps forward, as even a small shop with fewer than a dozen machines or employees can still meet or exceed the national productivity average. It's important to also communicate your growth plans — even the small ones — to your entire team.

4. Diversify According to Demand

"While it’s sometimes a bad idea to take on a job outside the capabilities of your shop when you're just starting out, new projects that seem within reach and will provide a cost-efficient result can be a helpful way to diversify your operations. If, for example, a lathing shop has the training and funds to undertake a profitable milling or plastic fabrication contract, then the resulting diversity can help provide sustainable growth even during periods when one sector of the market is on a downswing.

5. Remain Open to New Technology

"Even though a new technical innovation can be costly in terms of additional training and initial set-up, recently-developed equipment may have a positive long-term effect by simplifying production methods or providing the means to accomplish tasks that were once considered impractical. New technology can sometimes help a business remain competitive, especially if the innovation gains widespread notice.

"Shop owners might want to consider purchasing more manufacturing equipment to fulfill existing and future orders. This can be a difficult decision to make, as future growth isn't guaranteed and buying equipment has many upfront costs. On the positive side, however, new machinery equipment will increase production capacity and improve cycle times, which will in turn create more opportunities for your business. Business owners must weigh the risks versus the rewards — and again, communicate your efforts to your team accordingly.

"If investing in new machinery isn't an option, see if you can modify and update your current equipment. This approach requires a much lower investment than purchasing new items, but it can still help improve your production capacity and cycle speeds.

6. React to Your Competition

"Being aware of your main competitors is a valuable practice under most circumstances, particularly in times of economic volatility. For example, market fluctuations can cause a slowdown in commercial manufacturing, while leaving military production relatively unchanged (and vice-versa). In this case, competitors from one side of the spectrum may bring their operating standards to the other, forcing companies to accelerate their production rates or lower prices in order to maintain market share...

7. Be Flexible in Multi-Stage Processes

"Companies that combine both internal fabrication and machining operations can often save time or money by acquiring equipment that incorporates secondary work into its primary function. For example, using a cutting laser can often reduce the need for post-fabrication finishing, such as smoothing or evening edges.

8. Integrate Your Operations

"While vertical or horizontal integration is beyond the reach of many small CNC businesses, it may still be helpful to bring as much of the manufacturing process in-house as you can. Streamlining measures, such as organizing a production schedule around a machine shop’s in-house capabilities or prioritizing jobs based on your own production center rather than an external supplier’s availability, can help smooth workflow and ultimately improve output.

9. Initiate Scalable Growth

"In many cases, successful business growth is not dependent on the size of the products being manufactured, but on the depth of the fabricating process. It can be beneficial to evaluate the services or products you provide to your customers, and see if you can expand the reach of those services. For example, if you are producing steel tubing for your purchasers, see if you can also provide them with the fasteners used to join these components together. Securing more expansive contracts from existing relationships can be a secure and scalable method of growth.

10. Step-by-Step Value Addition

"CNC machining is essentially a multi-staged process in which there is the potential for value-added work at each stage. Consequently, a shop’s potential for expanding its business largely depends on how many of those value-added steps it is able to perform. A small business seeking to expand can evaluate its manufacturing strengths and take advantage of any opportunity to insert itself into a value-added production stage. This approach, coupled with gradual service integration and streamlining, can be a valuable way to expand your small CNC business.

11. Warehousing

"Equipment isn't the only part of the physical shop floor that needs to be changed if you're expanding your business. Storage facilities and warehouses should also be considered once you grow to accommodate additional production. If adding on to your current shop floor isn't an option, off-site warehousing might be the way to go. These facilities can be beneficial in lowering the additional costs of maintenance and overhead that are usually associated with running a warehouse..."

How CNC Machining is Utilized in the Aerospace Industry

Many industries take advantage of CNC Machining. Here is a brief look at how it is utilized in the Aerospace Industry.

According to Sony T with Techiexpert.com:

"All forms of air travel are included in the aerospace industry. Everything from planes used by commercial airlines to spacecraft designed for travel outside the comforts of our atmosphere. If it flies, it is a product of the aerospace industry. As you’d probably imagine, pinpoint accuracy and razor-sharp precision are vital when designing machines that will take to the skies.

"That’s why it is no surprise really that CNC or computer numerical control, is used so extensively in this field.

Industrial-Grade CNC Manufacturing

"As aircraft in its many forms moves at high speeds and needs to be as durable and safe as possible, specialized industrial-standard CNC manufacturing setups are used. There is a lot of money required to fund the various components and parts of aircraft. As such, only the wealthiest businesses around the world can invest in the automation required to build these forms of transportation.

CNC Use in Aviation

"Accuracy is important in aircraft construction. Whether it is fighter jets, cargo planes, passenger airlines. The accuracy required extends to all parts of the aircraft production process. That includes everything from the outer shell of the innermost parts. CNC machining can be integral to manufacturing the necessary tools accurately and at speed to ensure each part of the plane functions properly.

"For instance, the engine inside a plane needs to be able to keep the plane in the air for the duration of its flight, which means it needs to be able to use and process fuel. Some of the most seemingly insignificant pieces that are crucial to the running of an engine can be made using CNC machining.

"Consider also the cockpit. CNC machining could be used to create all the small and connected components that form the computer navigational system that helps the plane to get from a to b. Moving to the exterior of the plane, vital parts like the wings can be finetuned and tweaked with CNC machining to ensure they move through the air efficiently and safely.

CNC Use in Space Travel

"What organizations do you think of when you think of space travel? NASA and Space-X probably fall quickly off your tongue. It makes sense as these companies are responsible for designing and manufacturing some of the most powerful and technologically advanced rockets and spacecraft to allow for manned and unmanned missions across our solar system.

"To be able to do that, CNC machining has played an important role in the designing, planning and building of various parts of all kinds of rockets and other similar crafts. From the smallest and most minute fixtures and components to the body design of rockets.

"Spacecraft needs to be built to last and withstand life in space for long periods, ranging from a few weeks to many years. Because of this, that golden word ‘accuracy’ comes in to play again in this part of the industry. Not only do all the parts need to work well, but they need to ensure the spacecraft operate safely, to protect not just the crew (if there is one) but the expensive equipment on board as well as the craft itself."

Top 11 Myths Of CNC Machining

It does not come as a surprise that with the rise in CNC Machining's popularity, the number of myths around it have also risen.

According to Bryan Rosenberger with MachineDesign:

"Manufacturing can be an intimidating space for the uninitiated. With new machining processes and technology springing up on the market, it’s easy to become lost in the weeds and get scared off by the sheer volume of information available.

"CNC machining, in particular, can leave folks scratching their heads. Many believe that CNC is a piece of cake, and will dive into uncharted waters without the proper research and training. Others will steer clear of CNC machining entirely for fear that it is too large of an undertaking. The truth is, CNC machining can be extremely accessible, but it is helpful to understand what it is and is not before you get started. Below, we’ll dispel some common myths.

Myth #1: No Experience Necessary

"Machine manufacturers throughout the industry will all make claims about how user-friendly their CNC is. The latest machining centers come equipped with visual programming systems, automatic tool presetters, high-tech work probes and a wide variety of tools and add-ons to simplify the machining process. But at the end of the day, a machine is only as good as its operator, and it takes time to build up a familiarity with the CNC process and the tools and procedures required to effectively produce quality parts on a consistent basis.

"For anyone new to CNC machining, it’s always best to seek help from those with more experience. Training is available online and in-person through most machine retailers. Tooling and material vendors can help educate users on proper cutters, feeds/speeds, work holding, etc. Online forums are a great resource to post problems and seek solutions to challenges you may be facing. There is always something new to learn in the world of CNC machining.

Myth #2: “Set it and Forget it”

"There is a common misunderstanding that once you run a part on a CNC, it will continue churning out high-quality components without issue. It is true that there have been significant advancements in machine automation: Modern technology (bar feeders, part loaders, pallet systems and more) have made 'lights-out manufacturing' more accessible. Still, issues will always arise. Tools break. Parts shift. Inserts wear down. Sooner or later, it will become necessary for operators to intervene in order to maintain part quality and correct or prevent problems on the machine.

Myth #3: Predictability of Production Time

"With the advent of modern CAD/CAM systems, it has become increasingly simple to calculate production time for a given component. You can track cycle time for any number of parts, and you can even determine the run time for specific tooling operations. All of that information is fantastic for quoting and estimating how much machine time will go into a particular order. That said, CNC machining is never perfect. It can be difficult to anticipate when a certain tool will fail, or when a piece of equipment will break down and require maintenance. There are numerous ways to incur production delays, so it is always best to err on the side of caution when attempting to predict production time on your CNC.

Myth #4: G/M Code is a Thing of the Past

"To machine a part, a CNC needs to know what operations to perform and how to perform them. To accomplish this, operators used to type in a lengthy series of numbers and letters (known in the industry as G Code or M code) which were used to communicate with the machine and get it to execute its functions. Today, the vast majority of shops rely on 3D CAM systems (computer-aided manufacture) to define their tools, workpiece, cutting paths, drill cycles and more. Similarly, many machines rely on visual programming systems that allow operators to program parts by simply adding a few dimensions to a library of stock machining operations.

"Given these advanced programming tools, G/M Code should be obsolete, right? Wrong. Whether it's a visual system at the machine, or the latest CAM software, they all are outputting code. The same G and M code that operators have been using for decades, just without the headache of manually typing it in. This code can still be edited and tweaked by operators to improve cutting efficiencies, adjust offsets, change tool paths and more. Even a skilled CAM programmer would benefit from a basic understanding of the raw code, as it can be essential when troubleshooting errors and identifying problem areas during machining.

Myth 5: Everything is Automated

"We have seen incredible advancements in the world of machine automation. Many of these technologies have been adopted by large manufacturing outfits to increase capacity and speed up production. That said, even the most robust system of automation technology would not function without skilled operators and programmers.

"Machines fail, and it takes a human to get the system back up and running. It would be unwise to invest a great deal of time and money into the latest and greatest tech without a team of experienced CNC professionals overseeing the operation. While the automation equipment available today is impressive and exciting, the majority of shops are nowhere near full automation, relying on talented machinists and programmers to design and manufacture their parts.

Myth #6: CNC Machining is Expensive

"CNC machining is becoming more and more affordable. The combination of CAD/CAM software and modern machining centers has made it easier than ever to take a part from conception to production. Built-in CNC features allow operators to setup parts faster than ever, and today’s cutting tools and high-speed machining operations have significantly reduced cycle times. It can still be quite costly to run parts in small quantities, due to shop minimums and the operator/programmer time involved in each CNC job, but as production numbers increase, part prices can drop exponentially.

Myth #7: CNC isn’t for the Little Guys

"This is just plain wrong. With more and more machine manufacturers competing in the space, CNC equipment has never been more accessible. Machining centers come in every shape and size, so smaller shops are not limited by floor space. Most equipment providers offer machines in a variety of models with a wide range of optional features, which means customers can custom-order a CNC to meet their exact budget and specifications. Though still in its infancy, we have seen a growing market for desktop CNC machines as well. You could literally have a water jet or CNC mill running in a small office or classroom.

Myth #8: CNC Programmers Don’t Need to Know How to Machine

"The best programmers work closely with operators to understand the ins and outs of the machining process. Many programmers start out as machinists themselves. The information gleaned from time on the machine proves invaluable when sitting down to work in a CAM environment. While creating a program, there are a number of factors to account for including work holding, tool lengths, cutter types, speeds/feeds, machining paths and so much more. It is not uncommon for new programmers to generate a program that runs beautifully in their CAM software, only to watch it fail miserably when it reaches the machine. While you can learn to program successfully without a background in machining, it will be a long and challenging road.

Myth #9: A CNC Machine Can Make Anything

"There are no shortage of mind-blowing videos online highlighting the latest features of modern machining centers. Multi-axis mills and live-tooling lathes will produce some of the most beautiful and complex components you’ll ever see. That said, even the most advanced piece of CNC equipment has its limitations. Understanding a CNC’s capabilities is critical when designing and manufacturing parts. Some features simply cannot be machined. This could be due to a particular machine restriction, such as range of motion or cutting envelope. It could also be dependent on factors that go beyond the CNC itself such as tooling, material type, part geometry and more. Modern CNC machining centers can do amazing things, but there can always come a point when their limits will be reached.

Myth #10: CNCs are Built to Last

"Like it or not, CNC machines will break down. They operate under a great deal of stress and are subject to incredible amounts of wear and tear. Executing complex machining operations at high speeds will eventually take its toll, and sooner or later machine maintenance becomes a necessity. A skilled operator will not only be able to run the machine, but they will also be able to fix it when failures inevitably occur. A preventative maintenance schedule is highly encouraged to limit machine downtime and avoid unnecessary stoppages.

Myth #11: We’ve Seen it All in the World of CNC

"The manufacturing industry is constantly growing and evolving. Advancements in CNC machining have made technology that once seemed futuristic easily accessible for small shops, hobbyists and educators. Additive manufacturing has taken off, and we’ve only just begun to capitalize on all that 3D printing has to offer. There has never been a better time to get involved in the world of CNC machining, and it will be exciting to see what new products and equipment become available in the years to come."

CNC Machining Services for Custom and Low Volume Production

Manufacturing is an ever-changing field, but CNC Machining remains at the top in terms of short run manufacturing.

According to James Anderton with Engineering.com:

"In short run manufacturing, it’s hard to name a better technology than CNC machining. It offers a well-rounded mix of advantages including high throughput potential, accuracy and repeatability, a broad selection of materials, and ease of use. While almost any machine tool can be numerically controlled, computer numerical control machining typically refers to multi-axis milling and turning.

"To find out more about how CNC machining is used for custom machining, low volume production and prototyping, engineering.com spoke with Wayken Rapid Manufacturing, a Shenzhen-based custom prototype manufacturing service about the materials, technology, applications and operation of CNC machine tools.

Materials

"When it comes to materials, if it comes in sheet, plate or bar stock, chances are you can machine it. Among the hundreds of metal alloys and plastic polymers that can be machined, aluminum and engineering plastics are most common for prototype machining. Plastic parts designed to be molded in mass production are often machined in the prototype phase in order to avoid the high cost and lead time of mold making.

"Access to a wide range of materials is especially important when prototyping. Because different materials have different cost and different mechanical and chemical properties, it may be preferable to cut a prototype in a cheaper material than what is planned for the final product, or a different material may help optimize the strength, stiffness or weight of the part in relation to its design. In some cases, an alternate material for a prototype may allow a specific finishing process or be made more durable than a production part to facilitate testing.

"The opposite is also possible, with low cost commodity materials replacing engineering resins and high-performance metal alloys when the prototype is used for simple functional uses like fit check or mockup construction.

CNC Metal and Plastic

"Although developed for metalworking, plastics can be successfully machined with the correct knowledge and equipment. Both thermoplastics and thermosets are machinable and are very cost effective compared to short run injection molds for prototype parts.

Plastics

"Compared to metals, most thermoplastics like PE, PP or PS will melt or burn if machined with the feeds and speeds common to metalworking. Higher cutter speeds and lower feed rates are common, and cutting tool parameters like rake angle are critical. Control of heat in the cut is essential, but unlike metals coolant is not typically sprayed into the cut for cooling. Compressed air may be used to clear chips.

"Thermoplastics, especially unfilled commodity grades, elastically deform as cutting force is applied, making it difficult to achieve high accuracy and maintain close tolerances, especially for fine features and detail. Automotive lighting and lenses are particularly difficult.

"With more than 20 years of experience with CNC plastic machining, Wayken specializes in optical prototypes such as automotive lenses, light guides and reflectors. When machining clear plastics such as polycarbonate and acrylic, achieving a high surface finish during machining can reduce or eliminate processing operations such as grinding and polishing. Micro-fine machining using single point diamond machining (SPDM) can provide accuracy less than 200 nm and improve surface roughness less than 10 nm.

Metals

"While carbide cutting tools are commonly used for harder materials such as steels, it can be difficult to find the right tool geometry for cutting aluminum in carbide tools. For this reason, high speed steel (HSS) cutting tools are often used.

"CNC aluminum machining is one of the most typical material choices. Compared to plastics, aluminum is cut at high feeds and speeds, and can be cut dry or with coolant. It’s important to note the grade of aluminum when setting up to cut it. For example, 6000 grades are very common, and contain magnesium and silicon. These alloys provide superior workability compared to 7000 grades, for example, which contain zinc as a primary alloying ingredient, and have higher strength and toughness.

"It’s also important to note the temper designation of an aluminum stock material. These designations indicate the thermal treatment or strain hardening, for example, that the material has undergone and can affect performance during machining and in end use.

CNC Machining Technology

"Five axis CNC machining is more expensive complex than three axis machines, but they are gaining prevalence in the manufacturing industry due to several technological advantages. For example, cutting a part with features on both sides can be much faster with a 5-axis machine, since the part can be fixtured in such a way that the spindle can reach both sides in the same operation, whereas with a 3 axis machine, the part would require two or more setups. 5 axis machines can also produce complex geometries and fine surface finish for precision machining because the angle of the tool can be conformed to the shape of the part.

"Besides mills, lathes and turning centers, EDM machines and other tools can be CNC controlled. For example, CNC mill+turn centers are common, as well as wire and sinker EDM. For a manufacturing service provider, flexible machine tool configuration and machining practices can increase efficiency and reduce machining costs. Flexibility is one of the principal benefits of a 5-axis machining center, and when combined with the high purchase price of the machines, a shop is highly incentivized to keep it running 24/7 if possible.

Precision Machining & Micro-Fine Machining

"Precision Machining refers to machining operations which deliver tolerances within ±0.05mm, which is widely applicable in automotive, medical device and aerospace parts manufacturing.

"The typical application of Micro-Fine Machining is Single Point Diamond Machining (SPDM or SPDT). The main advantage of diamond machining is for custom machined parts with strict machining requirements: form accuracy less than 200 nm as well as improve surface roughness less than 10 nm. In manufacturing optical prototypes such as clear plastic or reflective metal parts, surface finish in molds is an important consideration. Diamond machining is one way to produce a high-precision, high-finish surface during machining, especially for PMMA, PC and aluminum alloys. Vendors that specialize in machining optical components from plastics are highly specialized, but offer a service that can dramatically reduce costs compared to short run or prototype molds.

Applications

"Of course, CNC machining is widely used in all manufacturing industries for production of metal and plastic end-use parts and tooling. However, in mass production, other processes such as molding, casting or stamping techniques are often faster and cheaper than machining, after the initial costs of molds and tooling is amortized across a large number of parts.

"That’s part of the reason why CNC machining services are ideal for prototyping.

CNC Machining vs. 3D Printing

"CNC machining is a preferred process for producing prototypes in metals and plastics because of its quick turn time compared to a process like 3D printing, casting, molding or fabrication techniques, which require molds, dies, and other extra steps.

"This ‘push-button’ agility of turning a digital CAD file into a part is often touted by 3D printing proponents as a key benefit of 3D printing. However, in many cases, CNC is preferable to 3D printing as well.

"It can take several hours to complete each build volume of 3D printed parts, while CNC machining takes minutes.

"3D printing builds parts in layers, which can result in anisotropic strength in the part, compared to a machined part made from a single piece of material.

"A narrower range of materials available for 3D printing may limit the functionality of a printed prototype, while a machined prototype can be made of the same material as the final part. CNC machined prototypes can be used for end-use design materials to meet functional verification and engineering verification of prototypes.

"3D printed features such as bores, tapped holes, mating surfaces and surface finish require post processing, typically via machining.

"While 3D printing does provide advantages as a manufacturing technology, today’s CNC machine tools provide many of the same advantages without certain drawbacks.

"Fast turnaround CNC machines can be used continuously, 24 hours a day. This makes CNC machining economical for short runs of production parts that require a wide range of operations.

Operation

"As the manufacturing market trends toward customization and diversification, leaving behind an old paradigm of one-size-fits-all mass production, CNC machining is proving to be a versatile solution to producing custom parts fast and flexibly. However, it isn’t enough just to use CNC machine tools. Using lean production methodology, process optimization, and control of production costs and supply chain will have a significant impact on productivity, too. In low-volume production of custom parts and prototypes, this impact is magnified, as setup changes and opportunities for waste occur more frequently..."

Sometimes the Trickiest Part of CNC Machining Is Holding the Part

When it comes to CNC Machining, finding the best way to hold the part can be the trickiest.

According to Modern Machine Shop:

"XL Machine was a Top Shops winning company in 2017. Plus, General Manager Chris Orlowski was part of a panel discussion with representatives from the other winning shops that year at our inaugural Top Shops Conference in Indianapolis.

"In checking back with him a few months ago, I learned about a neat robotic cell the Three Rivers, Michigan, shop had recently added to machine three- and four-blade cast propellers (a family of 20 part numbers) for outboard boat engines. I mentioned that holding such contoured parts for five-axis machining had to be tricky. In fact, that was the most challenging part of the project, he said.

"That, my friends, is a story hook, so I scheduled a visit to learn more.

Cell Structure

"Founded in 1976, XL Machine (now part of the Burke Porter Group) began as a prototype machining company. It still does prototype work today, but pairs that with production machining capability. The shop serves various customers in markets such as automotive, heavy industry, entertainment and marine.

"At first, the customer with the propeller job turned each part’s hub in house. XL Machine would then mill either side of the contoured blades on two stand-alone three-axis VMCs and a stand-alone HMC that blended the verticals’ cuts near the hub. When its customer asked it to turn the hubs as well, creating a multi-machine, automated process seemed like a logical next step...

"The U-shaped cell designed to finish these parts features four Okuma machines: two side-by-side 2SP-V760EX vertical lathes for op. 10 and op. 20 hub-turning work, and two MU 6300V five-axis machines for op. 30 and op. 40 blade-milling work. These machines are served by a large FANUC M-900ib robot.

"The cell includes two multi-level racks with drawers into which the cell operator places raw castings and removes completed parts. To start the process, the robot opens a drawer to grip a raw casting by its hub. A camera mounted above the rack views the part number on tabs on the end of each blade to verify the robot is picking the correct part. (These tabs are also used for locating and clamping the parts in the five-axis machines’ fixtures.) Another camera on the robot’s arm then detects the part’s orientation so the robot properly positions the gripper without contacting the blades.

"Next, the part is delivered to the op. 10 vertical lathe for internal and external machining of the hub half facing upward. The other half of the hub is secured by a custom power chuck from Co-Op Tool, a division of Hammill Mfg. The machine also uses a custom plunge tool from Cline Tool, which combines four operations into one cutter body. This is helpful because many tools for the turning and boring operations are so large that adjacent ATC pockets must remain empty to accommodate them. The custom cutter saves three ATC pockets. The machine also makes use of flood coolant and through-tool air delivery to help remove chips from the insides of the freshly machined hubs.

"Once op. 10 work is completed, the robot grips the part, the power chuck disengages and the robot takes the part to a flip station. The station then lowers, and the robot, now with the gripper, facing down, grips the other side of the hub. It then takes the part to the second lathe for op. 20 hub work, which is similar to the op. 10 work...

"Five-axis blade milling is next. The op. 30 machine mills one side of each blade, and the op. 40 machine mills the other side. This is where the trick fixturing created specifically for this application shines.

Workholding Props

"In addition to the custom lathe workholding devices, Co-Op Tool supplied the two unique hydraulic workholding fixtures for the op. 30 and op. 40 blade milling work. Dave Bermudez, the company’s senior design engineer, created the fixtures. When pallets of fixtured parts shuttle in and out of machine workzones, the pallet with locating elements that seat into the machine is typically separate from the fixture. However, given the size of the propellers, and being that Z-axis space is limited in such five-axis machines, the pallets had to be integrated into the fixtures themselves. Mr. Bermudez says this reduced the height of each fixture by approximately 4 inches. But he notes it also meant that hydraulic circuits that normally would be routed internally in the fixtures had to be plumbed externally.

"These fixtures feature a center collet chuck designed by Co-Op Tool onto which a propeller locates and is secured after the robot places it in the fixture. (Prior to clamping, the robot rotates the part slightly so the tabs contact stops to ensure proper positioning in the fixture.) Hydraulically actuated swing clamps from Vektek then move into position to pinch the tabs at the end of each blade. Next, spring-loaded workholding supports under each blade lock into position once they contact the underside of the part to prevent vibration during machining.

"Because each casting varies as to how much flash or extra material it might have, the single finishing pass is preceded by a roughing pass that removes extra material. This pass might do a good bit of air cutting, but it reduces the chance of tool breakage on the finishing pass.

"Touch probing is performed for both the op. 30 and op. 40 blade-milling operations. Once a fixture with part is loaded into a machine, a spindle-mounted touch probe locates the center and top of the hub to ensure it is properly positioned and seated in the fixture. It then touches off on the tabs to ensure the propellers are oriented correctly in the fixture. These probing routines add 10 minutes to the overall cycle time (bringing the total to 40 minutes), but the shop justifies this because they ensure proper positioning in the fixture. In addition, all cutting tools are probed to check for insert breakage before being delivered back to the ATC carousel. If it is determined that a tool did break, a redundant tool is called up and that operation is repeated.

"The final operation is milling away the tabs on each blade. This is done with the hydraulic swing clamps still pinching the tabs. The central collet chuck on its own provides sufficient holding force for these relatively light machining operations as each tab is cut off.

A Fitting Finish

"XL Machine’s propeller customer performs some subsequent polishing to the machined blades prior to assembly on its outboard engines. That said, Mr. Orlowski says the customer appreciates the quality finish of the machined blades because it minimizes polishing, especially in the corners where blade profiles transition to the hub. This required a bit of five-axis toolpath ingenuity. Specifically, a ball end mill is moved up and down the corners vertically rather than back and forth across the transition, which would leave behind multiple steps that would have to be removed. This little bit of toolpath ingenuity here takes care of the polishing.

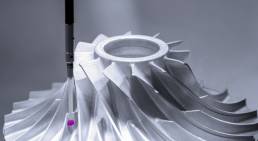

Precision CNC Supercharger Rotor Machining Means More Power

Founded by former race crew chief and car owner Art Whipple in 1987, this Fresno, California, company manufactures twin-screw superchargers for automotive and marine racers and anyone else looking to improve their engine’s performance. As one of a few different types of “power adders,” as they are commonly referred to (turbochargers and nitrous oxide are others), superchargers introduce additional air into an engine beyond what the engine can pull on its own. The more air that can be delivered into the engine, the more fuel that can be proportionally added.

Global CNC Machine Tools Market Growing

CNC Machine Tools Market" Report presents an outline of the related market comprising types, applications and top producers with new technology, characteristics, and market chain with the investigation and newest market trends and expansion. Further, the CNC Machine Tools Market research report explains potential industry supply, value, market demand, competition and its study of top players with industry estimate from 2019–2025. At present, the global CNC Machine Tools market is chiefly driven by a number of outstanding firms. The major market players are executing different growth strategies counting new product launches, strategic partnerships & collaborations, operational & geographical expansions, joint ventures, mergers & acquisitions, and sales to grab the superior business position.