4 Benefits of Outsourcing Manufacturing

Production needs can often be met completely in-house. However, if there are changes in demand or production capacity, the organization may require additional resources. If outsourcing alternatives exist, the company can be in a position to grow without accumulating overhead, tying up resources or suffering in order fulfillment unnecessarily. Following are four key benefits of outsourcing manufacturing.

Lower Labor Costs

Lower labor costs are one of the top benefits of outsourcing manufacturing. While there may be broader humanitarian and compliance implications at play, outsourcing under the right circumstances can be a viable option.

Labor can be performed at a fraction of the cost for some manufacturers with the right partnership. Most organizations find that they can achieve real savings and focus more on their core business when they consider outsourcing.

Fuel Innovation

Innovation can be brought to life much quicker through outsourcing. A company may not have the tools or production scheduling that permits creating new pieces or items. Access to an outsourcing resource makes it possible to quickly schedule prototyping and other production-related functions without reallocating internal resources.

Support Increased Demand

Outsourcing is wonderful for addressing an uptick in demand for different types of products. Companies may experience a sudden surge in orders for a particular product and may require additional resources to keep up with demand.

A lack of resources available to devote to production could affect an organization’s ability to meet fulfillment obligations. An outsourcing company can supplement existing in-house manufacturing efforts and make it easier to meet those new demands.

Contribute to Efficiency

There may be inefficiencies in the production process. If the organization has decided to handle all of its production needs internally, there may be inefficiencies that go unaddressed.

For example, a company may not have the capacity to tweak certain processes because of several different types of product design requirements that must be accommodated within the manufacturing facility. It is often much smarter to outsource manufacturing, especially if the outsourcing company is able to produce the product with greater efficiency.

The biggest advantages to outsourcing come with saving money on production costs and improving efficiency across the board. Indeed, it may be much more cost-effective to produce pieces with an alternative manufacturing resource in an environment where things can be made with greater efficiency.

Strides in the area of innovation and improved production capacity are additional advantages to working with an outsourced manufacturer.

Read more: 4 Benefits of Outsourcing Manufacturing

Understanding the Rise of Manufacturing in India

When many executives think about manufacturing, China is the first country that comes to mind. But there are other players grabbing a bit of that spotlight — like India. Despite the conventional wisdom that says India’s place in the global economy revolves around digital bits and services rather than material atoms, the country is starting to attract more attention for its manufacturing potential for a number of reasons: India is the third-largest economy in purchasing power parity after the U.S. and China, it has a large population of engineers and factory workers, its intellectual property is widely respected, and it is easy to find English-speaking managers there.

While Narendra Modi’s “Make In India ” initiative to promote manufacturing in India was mocked by some, North American executives are increasingly looking to expand their manufacturing supply chains beyond China. To decide if India is a good candidate for your operations, it’s important to understand the opportunities of doing business in the country — as well as the challenges.

American success stories in India

While American companies are only starting to explore India’s potential for manufacturing, we’re already seeing a few examples of how these efforts can be successful. For example, Chicago-based Abbott, which operates in 150 countries and owns top brands such as Similac infant formula, recently built a manufacturing facility in Jhagadia, Gujarat, in order to compete in India’s large growing nutrition market. In 2014, its 14,000 employees in India generated $1.09 billion in sales. This is largely because it manufactures products that reflect the local environment (to deal with spicy Indian food, it sells the antacid Digene), and are widely used there (to manage aches and pains, most Indians are prescribed Abbott’s Brufen when they want ibuprofen). It also adapts some its products to meet local expectations — for example, the plant caters to Indian mothers by manufacturing a version of the popular kids’ nutritional supplement PediaSure that is flavored with saffron and almonds.

India was one of the first expansion markets for Abbott, after Canada and the U.K, and today it’s the company’s third largest market globally — all six of the company’s business units have a presence in the country. “Last year, we signaled that India is a key manufacturing destination for us with a $75 million investment,” Abbott Vice President Bhasker Iyer told us. “It is one of the fastest growing markets globally — with a young population, strong macroeconomic indicators, a huge consumption story, and a politically stable government working to accelerate reforms. For a healthcare company, the reasons to be part of this vibrant country are even more compelling — it’s an opportunity to serve the unmet healthcare needs of a 1.2 billion population.”

Read more: Understanding the Rise of Manufacturing in India

What You Need to Know about Manufacturing in India

For businesses looking to join eCommerce with a competitive advantage, one of the best things to do is find a manufacturing sector that isn’t saturated with international businesses. In India, the manufacturing sector has evolved from its earlier stages of industrialization to its current phase of global competitiveness, making it a great location for newer, smaller businesses to manufacture.

Before it becomes overrun by foreign brands, now is the time to connect with manufacturers, gain access to the advancing production capabilities, and start creating relationships with the suppliers for better rates down the road.

The manufacturing sector in India is progressing largely due its location nearby the export giant, China. China remains the largest exporter of goods to India, sending textile materials, plastics and rubber precious metals to suppliers. The trade reliance on China for raw materials continues to impact the growth of India’s textile industry, but the nation is also becoming less dependent as production of raw materials starts to rise. For example, cotton production is forecasted to increase by 9.3 percent YoY.

The Indian textile industry is only second in size to China. More than 50 percent of India’s textile exports are cotton based, but suppliers also manufacture synthetic fabrics, wool, and silk. The textile sector is one of the oldest industries in India, so Indian suppliers differentiate by implementing antiquated, quality-focused techniques in the production of goods like knitted custom clothing garments.

Over 45 million people work in the Indian textile industry, making it one of the largest sources of employment generation in the country. With so many workers in the industry, suppliers will likely expand and create more opportunities for foreign brands to manufacture. There’s untapped potential in the manufacturing sector for smaller eCommerce retailers.

Read more: What You Need to Know about Manufacturing in India

How manufacturing in India can become globally competitive

With $2.3 trillion in GDP, India is the world’s ninth-largest economy and the third largest by purchasing power parity at $8 trillion. Yet manufacturing accounts for only 16 percent of the country’s GDP, compared with the services sector’s nearly 52 percent. India represents only 2 percent of the world’s manufacturing output, a tenth of what its neighbor China contributes. Clearly, India is punching below its weight in manufacturing.

Growth in manufacturing is crucial for India’s economic development. To capitalize on the demographic dividend, India must create nearly one million jobs per month over the next decade. Manufacturing has the potential to provide large-scale employment to the young Indian population and thereby enable a significant section of the population to move out of poverty. With this in mind, the Indian government has adopted “Make in India” as a core policy initiative to encourage and accelerate growth of the country’s manufacturing sector.

India has several strengths that could help it become a manufacturing powerhouse: a large pool of engineers, a young labor force, wages that are half that of China’s, and significant domestic consumption of manufactured goods. These factors become especially important as China, the world’s preeminent manufacturing destination, faces peak labor shortages and exponential wage growth.

India does have a few shining examples of world-class excellence in manufacturing and well-established core sectors such as textiles, auto components, and, more recently, petrochemicals. For example, Bharat Forge’s Mundhwa plant, the world’s largest forging factory, is a state-of-the-art complex that has placed India on the world map for manufacturing. The company has all the necessary attributes: heavy investment in technology, a scientifically skilled workforce, and a sharp focus on lean manufacturing.

Yet, manufacturing executives continue to wonder if manufacturing in India is globally competitive. If not, what are the main issues inhibiting the country’s ability to compete with the best in the world, and how can those issues be addressed? Answers to these questions will determine if companies should set up shop or expand their manufacturing footprint in India.

Competitive analysis

To better understand the global competitiveness of manufacturing in India, we undertook a comprehensive analysis, benchmarking select manufacturers against their peers around the world. We used Kearney’s proprietary Global Excellence in Operations (GEO) framework to assess manufacturers across six dimensions of operational excellence (see sidebar: About global excellence in operations). We found a correlation between operational excellence and industry, with automotive manufacturers typically leading the field, followed by large series manufacturers of consumer goods. Since geographic comparisons are influenced by distribution differences for industry types across regions, we analyzed a sample of sites that feature similar types of manufacturing and are represented evenly across all major manufacturing regions. Our findings were validated in one-on-one interviews with industry leaders and subject-matter experts.

Read more: How manufacturing in India can become globally competitive

Strong US Dollar Makes Engineered Components from Cost Competitive Countries an Attractive Buy

Purchasing power due to the strengthening US dollar has made engineered components imports an attractive buy, according to the Wall Street Journal. Economists expect this purchasing power to last through mid-2023.1

Although purchasing power can be seen across cost competitive countries, China is at a disadvantage from the continuation of import tariffs that have been in place since mid-2018.2 3

Indian manufacturing is an attractive choice for engineered component imports. One US dollar buys 82.31 Indian rupee today, compared to 76.31 Indian rupee just six months ago.

A comparison of currencies shows the strength of the U.S. dollar vs the Indian rupee:4 5

Keywords: Manufacturing, India, Indian Manufacturing, Engineered Components, Imports

1Bob Tita, “Strong Dollar Pressures U.S. Manufacturing Rebound,” The Wall Street Journal, October 9, 2022, https://www.wsj.com/articles/strong-dollar-pressures-u-s-manufacturing-rebound-11665307981.

2Ana Monteiro, “US Seeks Public Comment on Review of Trump-Era China Tariffs,” Bloomberg, October 12, 2022, https://www.bloomberg.com/news/articles/2022-10-12/us-seeks-public-comment-on-review-of-trump-era-china-tariffs.

3Kenneth Rapoza, “New Data Shows U.S. Companies Are Definitely Leaving China,” Forbes Media LLC, April 7, 2020, https://www.forbes.com/sites/kenrapoza/2020/04/07/new-data-shows-us-companies-are-definitely-leaving-china/.

4“Currency Converter: Live Currency Exchange Rates Calculator,” Forbes Media LLC, accessed October 14, 2022, https://www.forbes.com/advisor/money-transfer/currency-converter/.

5Taylor Tepper, “Why is the U.S. Dollar So Strong Right Now?” Forbes Media LLC, September 30, 2022, https://www.forbes.com/advisor/investing/strong-dollar/.

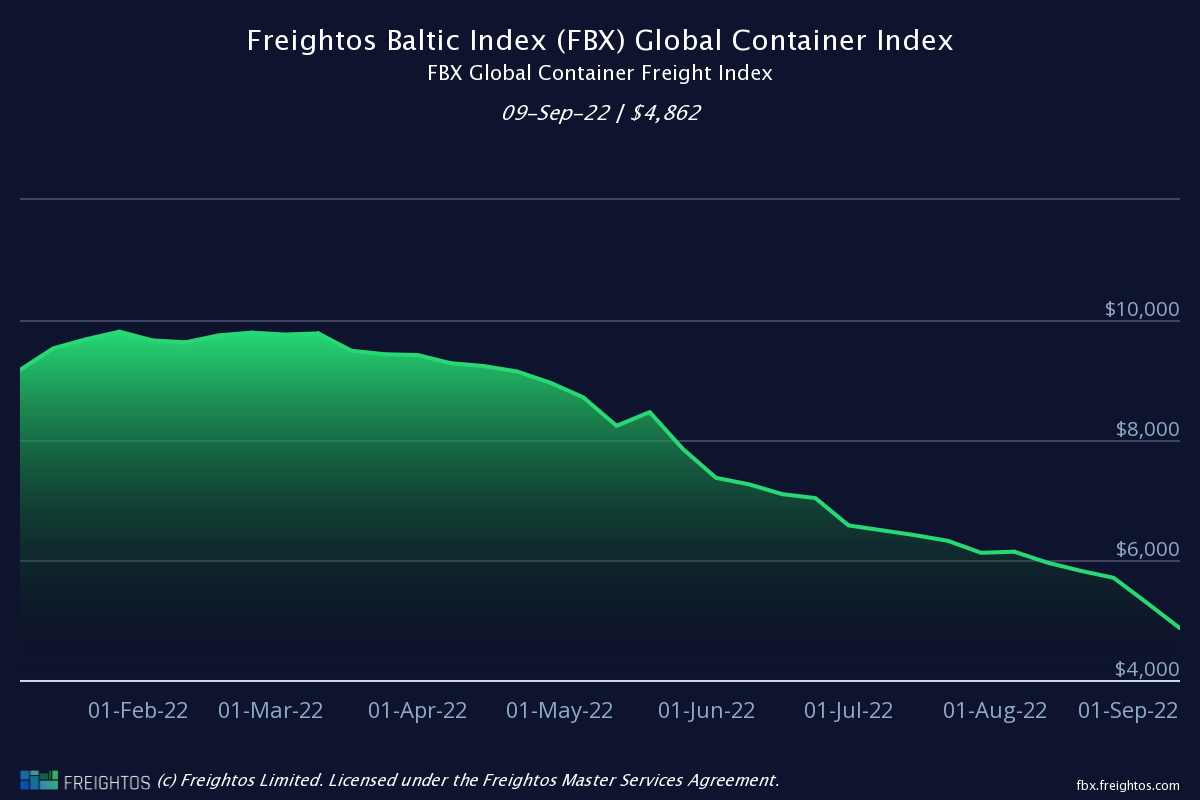

Market Rates for Shipping Container and Freight Transportation Have Dropped

Market rates for the transportation of shipping containers have dropped 50% since January 2022, per the Freightos Baltic Index (FBX), the leading international freight rate index.1

Spot-market container shipping rates have dropped and are forecasted to continue this trend through the end of 2022 and into 2023 according to Jonathan Roach, Container Trade and Shipping Analyst at Braemar, a London-based expert advisory group in shipping investment, chartering, and risk management.2

According to Peter Sand, Chief Analyst at Xeneta, a freight market-analytics firm, shippers are benefiting from “freight rate reversal”.3 Xeneta said in an August report that spot-market container shipping rates have declined so rapidly prices have come closer to long-term contracts which have been traditionally lower.4

Keywords: Shipping, Container, Freight, Transportation

1“Freightos Baltic Index (FBX): Global Container Freight Index,” Freightos Ltd, accessed September 15, 2022, https://fbx.freightos.com/.

2Costas Paris, “Ocean Shipping Rates Have Plunged 60% This Year,” The Wall Street Journal, September 5, 2022, https://www.wsj.com/articles/ocean-shipping-rates-have-plunged-60-this-year-11662375780.

3Augusta Saraiva, “Companies See Relief in Falling Spot Rates for Transpacific Freight,” Bloomberg L.P., June 23, 2022, https://www.bloomberg.com/news/newsletters/2022-06-23/supply-chain-latest-ocean-freight-rates-are-falling.

4Sonal Mishra, “Xeneta In the News Week 36, 2022,” Xeneta AS, September 8, 2022, https://www.xeneta.com/blog/xeneta-in-the-news-week-36-2022.

5 G-Code Tips for Increasing CNC Efficiency

Recently, these columns have focused on factors that contribute to the productivity of G-code programs, such as consistency, compatibility, ease of use and safety. Improving programs in these areas usually results in better machining efficiency. That is, when making programs more consistent and compatible, easier to use and safer to run, the machines — and the people running them — can naturally be more productive.

When it comes to efficiency, however, one must be careful. When doing something that improves efficiency, the machining may become more difficult and, in turn, more dangerous. By increasing the proficiency of the people running the machine, this may be an acceptable outcome. Having greater proficiency will allow CNC users to safely perform more complicated tasks.

That said, I will concentrate here on G-code programming techniques that improve efficiency and do not — for the most part — sacrifice usability or safety. There are, of course, countless improvements that one can make to processing, fixturing and cutting tools that will help reduce program execution time. But here we concentrate on techniques that are free, requiring only restructuring a program to execute more quickly.

As with all my columns about productivity, my intention is to inspire readers to consider their own CNC environment and look for ways it can be optimized. Use my suggestions to get started.

The Shortest Distance

When possible (and safe), ensure that as many axes are moving together during non-cutting commands. This includes approach, retract and motions as tools move from one machined surface to another. When approaching during machining center programs, however, if the operators are accustomed to seeing X/Y axis movements first, then the Z axis movement, they may be nervous about seeing all axes moving together within 0.1 inch (2.5 mm) of the work surface. If so, bring the tool 1.0 inch (25.0 mm) above the work surface in the Z axis first, then rapid the rest of the way in Z axis.

Internalize M Codes

Be sure to include M codes with motion commands whenever feasible. This includes spindle on and off and coolant on and off. This way, the M code’s activation time will be internal to the time it takes to make the motion (or vise versa). This is especially important with machines that allow only one M code per command. For these machines, it is impossible to start or stop the coolant and spindle at the same time unless the machine builder provides additional M codes for this purpose.

Efficiently Program Automatic Tool Changers

While this may be common knowledge, here are a few reminders:

- Include an M19 in the tool’s movement to the tool change position. This will align the key in the tool change arm with the keyway in the tool holder during the motion.

- For double-arm tool changers, always get the next tool ready (specify the T code for the next tool) soon after making a tool change.

- For short machining cycles, be sure tools are loaded consecutively in the tool changer magazine.

Read more: 5 G-Code Tips for Increasing CNC Efficiency

How These 4 Industries Benefit The Most From Precision Machining

Everything, from the medical field to the maritime industry and other industries, relies on machining components. Due to the rise of both machines and computers, precision machining services, such as Moseys precision machining company, provide high-quality precision machining services that allow for better intricate custom-made designs than other production processes can accomplish.

With the benefits of the precision machining process, including quicker development and manufacturing, more significant and guaranteed accuracy, and removal of human error, many manufacturers are saving money and time by providing their factories and workshops with CNC machines.

To enlighten you about this process, below are the top industries that benefit from CNC precision machining.

Medical Industry

The medical world is among the industries that benefit from precision machining. Hip replacements have become much more accurate using CNC-produced replica hips instead of the traditional replacement method. On top of being more precise in shape, CNC hip replacements are long-lasting, and manufacturers can make them much faster than the conventional versions. By eliminating the likelihood of human error, medical professionals also eliminate the possibility of a required second operation.

Besides that, dental practitioners need to recreate the identical shape and size of a cavity that must be veneered or crowned. Precision machining—coupled with 3D imaging techniques—can accurately recreate such a small shape and size, making dental procedures much more manageable for patients and dentists.

Furthermore, precision machining also has a significant impact on surgical implants. Patients who require surgical implants in the body to strengthen or replace broken bones used to need cautiously hand-crafted items fitting for them. These items were time-consuming to make and accurate to only a certain level. But with CNC precision machining, manufacturers today can produce even the most miniature and complicated surgical implants quickly and with better accuracy.

Read more: How These 4 Industries Benefit The Most From Precision Machining

Die Science: The basics of die design, Part II - Choosing die guidance components

In Part I of this two-part series, I discussed the process of selecting a die set type and thickness. Now let’s discuss various commercially available die guidance components and some basic guidelines for deciding which type is best suited for your operation.

Basic Guide Pin Function

First, let me make this statement: The function of the guide pins is to locate the upper and lower shoes or castings properly so that all of the die components mounted on the upper and lower shoe can interface with each other precisely. They guide cutting and forming components and sections so that the correct clearance can be achieved and effectively maintained. Guide pins are not intended to help guide the ram of a poorly maintained or sloppy press!

The press must be independently guided with precision.

A gentleman once told me, “Dies make parts, presses don’t.” My response was, “With all due respect, sir, both the die and the press are part of a system. Each one must function as the engineer intended it to function.” Needless to say, he was having many press-related stamping problems.

One of the statements I make in every training session I conduct is, “You can build and design a jewel of a tool, but if you put it into a glorified 200-ton trash compactor, you're going to have problems.” Don’t try to compensate for a poorly maintained or sloppy press by choosing oversized or considerably more guide pins on a die set.

Guide Pin Types

Guide pins, sometimes referred to as guide posts or pillars, function together with guide bushings to align the upper and lower die shoes precisely. They are cylinder-shaped pins made of hardened tool steel, precision-ground often within 0.0001 in. The two basic types of guide pins are friction pins (often called plain bearing pins) and ball bearing pins (also called ultraprecision guide pins). The pins fit precisely into a precision-ground sleeve called a bushing. Like guide pins, bushings often are ground to within 0.0001 in.

Friction pins (see Figure 1) are slightly smaller (usually about 0.0005 in. smaller) than the guide bushing's inside diameter. Friction pins and bushing typically cost less than ball bearing-style pins and are used commonly when a great deal of side thrust is expected in the die. Because they generate a great deal of friction, they are not desirable for high-speed stamping operations. To minimize the friction, the bushings usually are lined with a wear-resistant material called aluminum-bronze that may contain graphite plugs to reduce friction further. In addition, friction pins often are lubricated with high-pressure grease.

One common problem associated with using friction pins is that it often makes the process of separating the die quite difficult, especially larger dies. Care must be taken so that the die is separated in such as fashion that the upper and lower die shoes remain parallel during the separation process. Cocking the die may result in bending a guide pin. For larger dies, a special hydraulic machine called a die separator is often utilized to assist in the separation of the dies.

Read more: Die Science: The basics of die design, Part II - Choosing die guidance components

The Case for Abrasive Finishing Tools in CNC Applications

With advances in abrasive technology, machining center operators can complete surface finishing simultaneously with other machining operations to speed cycle times, improve quality and save on offline finishing time and costs. As a result, contract machine shops are increasingly turning to abrasive finishing tools that can be integrated easily into CNC machine carousels or toolholding systems. However, in doing so, questions can arise about the use of abrasive materials in expensive CNC machining centers. The concern is often a generalized impression that these abrasives act like sandpaper and release large amounts of grit and debris that could potentially clog coolant lines or damage exposed slides or bearings.

“These are very expensive, very accurate machines,” says Janos Garaczi, president of Delta Machine Co. LLC, a machine shop located in Gardena, California, that specializes in complex, tight-tolerance parts made of titanium, nickel alloys, stainless steel, aluminum, plastics and other exotic alloys. “I wouldn’t do anything to jeopardize the accuracy or lifespan of the equipment.”

Abrasive Distinctions

A closer examination of abrasive tools demonstrates that these concerns are largely unfounded. Although abrasives are often lumped into the same category, a distinction must be made between abrasives used for aggressive material removal and abrasive finishing tools. According to Brush Research Manufacturing, which is based in Los Angeles, finishing tools release little to no abrasive grit during use, and the amount generated is comparable to the metal chips, grinding dust and tool abrasion created during the machining process itself.

Even if minimal fine solids are produced, the filtration requirements for abrasive tools are not much different than those for machining. Any particulate can be easily removed using inexpensive bag or cartridge filtration systems, says Jeff Brooks of Filtra Systems, a company specializing in industrial filtration systems, including those for CNC coolant.

“A disposable media vacuum filter or pressure filter is the most cost-effective option for the end user for filtration that will achieve the high clarity levels required,” Mr. Brooks says.

“For fine honing work, I would recommend a 20-micron bag or cartridge filter, at minimum, to catch any fine solids and adequately protect the tool, the sump pump and keep the coolant ports from clogging,” says Chris Erato, director of sales at Oberlin Filter, a manufacturer of separation filtration for CNC coolant systems.

Read more: The Case for Abrasive Finishing Tools in CNC Applications