Tips, Tricks and Best Practices for Efficiently Generating Productive CNC Programs

Last May, the consulting firm Deloitte and The Manufacturing Institute—the workforce development arm of the National Association of Manufacturers (NAM)—published a joint study. Among its many alarming conclusions was the news that finding the right manufacturing talent “is now 36 percent harder than it was in 2018, even though the unemployment rate has nearly doubled the supply of available workers,” and that the “skills gap in the U.S. could result in 2.1 million unfilled jobs by 2030.”

Defining the Need

The solution, of course, is automation. Lots and lots of automation. When lathes, machining centers and other CNC machine tools have robots tending them, much of the angst over finding skilled operators falls by the wayside. Not only that, but with some additional investment in automated workholding, machine monitoring software, in-process probing systems and no small amount of effort and planning, machine shops can gain a shift or two of unattended operation.

It won’t be easy—and some will be more successful at it than others. But rest assured that American manufacturing will find its way past this seemingly disastrous situation, just as it has so many others.

Except for one thing: Robots can’t program themselves—not yet at least. Nor can they program the CNC equipment they’re responsible for keeping operational. Until they’re able to perform this complex task, the machining and sheet metal fabrication world will still need CNC programmers—people skilled in manufacturing and proficient with computers and software systems.

There’s certainly no lack of people with these skillsets. Those who belong to Generation Z and even many Millennials began using mice and keyboards while still mastering their ABCs. Unfortunately, there are no shortcuts to teaching them about manufacturing, CNC machine tools and the most effective way to drive end mills and turning tools through big chunks of metal. It takes years of training and experience before most shop folks make the leap to programming, during which shops will continue to struggle with the ongoing shortage of skilled CAM operators.

Even here, though, there’s good news on the horizon: CAM systems are getting smarter by the day, thus lowering the proficiency bar to some degree. Automated feature recognition, knowledge-based machining, advanced toolpath simulation and digital twins are just a few of the CAM technologies making programming more of a technical exercise than the tribal knowledge-inspired art form it has long been.

No Tricks, Just Hard Work

There are very few “tricks” to programming CNC machine tools. Developing accurate, efficient toolpaths depends in large part on the programmer’s skill as a machinist, together with the CAM software’s capabilities. The job is getting easier as CAM becomes more intelligent, but it remains challenging work—and very few machine shops can boast they have no room for improvement.

Read more: Tips, Tricks and Best Practices for Efficiently Generating Productive CNC Programs

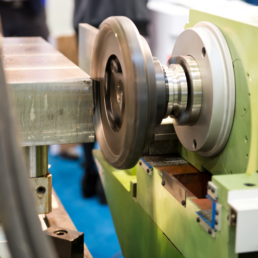

Horizontal Turning Center Features Thermal Compensation

Romi’s new GL 250 horizontal turning center features thermal compensation with sensors to maintain stable, dimensional results. According to Romi, the use of sensors provides accurate, real time compensation as opposed to compensation based on pre-defined algorithms. The result is more accurate machining over extended periods of time when the machine temperature increases.

The GL 250 has a maximum cutting diameter ranging from 11" (282 mm), and a z-travel of 23.6" (600 mm). The new machine is designed for medium- to high-production environments and features high power, torque and feed force, in addition to rigidity and precision attributed to the monoblock base.

Additionally, the new turning center is constructed with durable roller ways on all axes to produce high rigidity. A built-in spindle motor with a chiller incorporated and direct drive servo-motors reportedly facilitates high response speed, accuracy, less vibration and lower maintenance requirements. Romi says chilling the motor increases life expectancy and produces less thermal expansion.

The GL 250 also features a tailstock that is programmable and servo-driven. Position, speed and force are determined directly via the FANUC controller that reduces setup time. The turning center also inclues a 12-station turret with a choice of fixed tools with a Romi disk, driven tools with a VDI (Verein Deutscher Ingenieure) or BMT (base-mounted turret) disk, driven tools with y-axis or dual spindle with driven tools and y-axis.

The CNC control features a FANUC Oi-TF with 15" LCD touchscreen and Fanuc 32iB with 19" LCD touchscreen for dual spindle version machines and is the newest generation of FANUC’s Series iHMI. It is designed to produce faster, more accurate performance for turning applications with separate areas on the main screen for planning, machining, improvements and utilities. Functions are said to be accessible with just two clicks, and the system comes standard with an Ethernet interface, as well as a compact flash card and USB ports.

Read more: Horizontal Turning Center Features Thermal Compensation

Best Practices: Machining Difficult Materials

Steel, cast iron and aluminum are the workhorse metals most industries rely on. However, working in the aerospace, defense or medical industries often means working with difficult metals. These shops rely on hardened steel, titanium, heat-resistant nickel alloys and other materials that are notorious for the difficulties they present to machinists.

When working with exotic and difficult to machine metals, following correct practice is key. “Machining hard metals is a delicate process,” said David Moore, an applications engineer with Methods Machine Tools. “There’s a lot of room for error, machining takes more time, and you have to fine-tine every aspect of your process. When you’re dealing with expensive, exotic materials, preparation is critical.” We sat down with Moore, and others at Methods Machine Tools to discuss correct practices for working with difficult materials.

Cutting Tool Management

When cutting difficult materials, one of the most important considerations is the cutting tool itself. “Getting the tools to last is one of the biggest challenges,” says Ben Morone, another applications engineer from Methods. Harder metals can eat through the wrong inserts almost as quickly as you can replace them, and some materials warp and bend in ways that can keep heat trapped in the cutting tool.

Moore and Morone both emphasize how valuable it is to have the right coating. “Coating is very important, especially with harder materials.” says Moore. “If you use a standard coating on a carbide end mill, you’re going to burn through that quick. If you use the proper coating – with the proper speeds and feeds from your vendor – you’re going to be able to fly through the material, you won’t burn up your cutters, and you will hold to tolerance.”

Read more: Best Practices: Machining Difficult Materials

Choosing Your Carbide Grade: A Guide

While the metallurgic term “carbide grades” refers specifically to tungsten carbide (WC) sintered with cobalt, the same term has a broader meaning in machining: sintered tungsten carbide combined with coatings and other treatments. For example, two turning inserts made of the same carbide material but with a different coating or post-treatment are considered different grades. Carbide and coating combinations lack classification standardization, however, so different cutting tool suppliers use different names and classification methods for their grade charts. This can make grade comparison difficult for the end-user, an especially trying problem given that carbide grade suitability for a given application dramatically affects possible cutting conditions and tool life.

To navigate this maze, users must first understand what constitutes a carbide grade and how each element influences different aspects of machining.

What is the Substrate?

The substrate is the bare material of the cutting insert or solid tool underneath the coatings and post-treatments. It is typically made up of between 80- and 95-percent WC. To give the substrate the desired properties, material manufacturers add various alloying elements. The main alloying element is cobalt (Co) — higher levels of cobalt lead to greater toughness, while lower levels of cobalt lead to greater hardness. Very hard substrates can reach a hardness of 1800 HV and provide excellent wear resistance, but are very brittle and are only suitable for very stable conditions. Very tough substrates have a hardness of around 1300 HV. These substrates can machine only at lower cutting speeds and wear out faster, but have better resistance to interrupted cuts and unfavorable conditions.

The right balance between hardness and toughness is the most crucial factor when selecting a grade for a particular application. Picking a grade that is too hard can lead to micro breakages along the cutting edge or even catastrophic failure. At the same time, a grade that is too tough will wear out fast or require decreasing the cutting speed, thus reducing productivity. Table 1 provides some basic guidelines for selecting the correct hardness:

Read more: Choosing Your Carbide Grade: A Guide

Global CNC Machine Tools Market 2022 to 2028 Growth Prospects and Top Industry Players

MarketandResearch.biz has recently released Global CNC Machine Tools Market from 2022 to 2028, which provides current, historical, and evolutionary patterns in the CNC Machine Tools industry. The report examines the market, which is divided into five major regions. It features a section dedicated to the major players in the sector. This part includes an introduction of the company, a segment and brand overview, financial performance, and advancements made by the company to keep ahead of the competition. This analysis looks at market definitions, classifications, applications, engagements, and worldwide CNC Machine Tools enterprise trends.

Past growth trends, current growth factors, expected future outcomes, history, and the overall market’s future growth potential and essential traders are examined in the research.The study examines the many growths, potential, and segmentation trends in the global CNC Machine Tools market and the competitive landscape. Our researchers went to great lengths to ensure that the research was as open and honest as possible.

The paper details the findings of an industry-wide investigation into the dynamics of the parent industry. The study employs a multidisciplinary approach to uncover new opportunities and untapped potential in the global CNC Machine Tools market.The report is entirely based on primary and secondary sources of information. Only authenticated data is gathered and used for market derivation in secondary research since the raw data is filtered and checked at each phase.

Read more: Global CNC Machine Tools Market 2022 to 2028 Growth Prospects and Top Industry Players

Press Forging Machine Market Size And Forecast

New Jersey, United States – Comprehensive analyzes of the fastest-growing Press Forging Machine Market provide insights that help stakeholders identify opportunities and challenges. The markets of 2022 could be another significant year for Press Forging Machine. This report provides insight into the company’s activities and financial condition (a company profile is required if you wish to raise capital or attract investors), recent developments (mergers and acquisitions), and recent SWOT analyses. This report focuses on the Press Forging Machine market over the 2029 assessment period. The report also provides a Press Forging Machine market growth analysis which includes Porter’s five-factor analysis and supply chain analysis.

It describes the behavior of the industry. It also outlines a future direction that will help companies and other stakeholders make informed decisions that will ensure strong returns for years to come. The report provides a practical overview of the global market and its changing environment to help readers make informed decisions about market projects. This report focuses on the growth opportunities that allow the market to expand its operations in existing markets.

The report helps both major players and new entrants to analyze the market in-depth. This helps the key players to determine their business strategy and set goals. The report provides key market information including niche growth opportunities as well as Press Forging Machine market size, growth rate, and forecast in key regions and countries.

The Press Forging Machine report contains data based on rigorous primary and secondary school studies using research best practices. The report contains exhaustive information that will allow you to assess each segment of the Press Forging Machine market. This report has been prepared considering various aspects of market research and analysis. It includes market size estimates, market dynamics, and company and market best practices. Entry marketing strategy, positioning, segmentation, competitive landscape, and economic forecasts. Industry-specific technology solutions, roadmap analysis, alignment with key purchasing criteria, in-depth benchmarking of vendor products

Read more: Press Forging Machine Market Size And Forecast

Hybrid Additive Manufacturing Market Demands, Regional and Global Analysis, Industry Size, Trends and Revenue by Forecast 2027

Hybrid Additive Manufacturing Market report presents top to bottom examination of the market for estimating income, return on investment (ROI) and developing business strategies. Market shares of key players in the major areas of the globe such as Europe, North America, Asia Pacific, South America, Middle East and Africa are also studied. Here, market analysis makes an assessment of the expected rise, growth or fall of the product in the specific forecast period. An analytical assessment of the competitors confers clear idea of the most important challenges faced by them in the present market and in upcoming years.

Market Analysis and Insights

Hybrid additive manufacturing market will reach at an estimated value of USD 8.43 billion and grow at a rate of 24.30% for the forecast period of 2020 to 2027. The growing demand from aerospace sector is a vital factor driving the growth of hybrid additive manufacturing market.

Hybrid manufacturing is defined as a combining of additive manufacturing and subtractive manufacturing in a single machine system. Additive manufacturing is also known as 3D printing, which is used to build up a component, part or structure within another part, traditional subtractive manufacturing, or computer numerical control (CNC) milling among others.

The rising demand for hybrid systems due to the provision of both additive and subtractive operations in a single system across application industries is the vital factor escalating the market growth, also robust nature and lightweight components of the hybrid systems, that are used in the manufacture of medical components and tools, rising manufacturing activities in the aerospace and automotive industries in the U.S., hiking investments for intelligent production solutions to gain efficient performance and productivity and rising expansion of healthcare facilities and the growing healthcare budget are the major factors among others driving the hybrid additive manufacturing market. Moreover, continuous research and development activities, and modernization and technological advancements in the machinery will further create new opportunities for the hybrid additive manufacturing market in the forecast period of 2020- 2027.

Forging Ahead With Hybrid Steel

Patrik Ölund explains how the latest addition to a family of steel products is creating new opportunities for near net shape forming operations

Traditionally, steels were classified into four general categories: tool steel, stainless steel, engineering steel and maraging steels. In 2017, the launch of Ovako’s Hybrid Steel created a new family of grades with an innovative alloying philosophy. The result is that the key properties of each category are available in one high-performance steel (Fig.1.).

The family has now grown to include Hybrid Steel 50, a grade that offers exciting possibilities for component manufacturers to dispense with the need for quenched and tempered steel. By using the new grade, they can forge their component to near net shape, machine it in a soft condition and then apply a simple ageing treatment to achieve the final hardness required.

Two well-established precipitate phases are combined to strengthen Hybrid Steel: alloy carbide and inter-metallic. It also uses a creative alloying philosophy that minimises segregation. An important feature is that the significant levels of aluminium enable a strong combination of attractive properties. This is because aluminium reacts with nickel to form very small inter-metallic precipitates, but nearer the surface it also helps to form a protective oxide barrier.

Read more: Forging Ahead With Hybrid Steel

Prototyping Process: Steps & Best Practices

According to Study.com:

Testing Designs

A design team in Smallville has spent the past few days brainstorming ideas for a new community center prototype. They must consider the wants and needs of the old center's visitors and members of the town. The team thinks that they want to create a digital model for the community center that will enable testers to experience the center in a more truth-to-life application. But, is that the best way?

Members of the team have performed some research to help them navigate the prototyping process, or the creation of a model that allows for testing before the actual model is finalized. Here are some things they learned about walking through the prototyping process and best practices for creating effective prototypes.

Prototyping Steps

The first thing the team learned are the parameters they should use for building a prototype. Whether it's drawn on paper, rendered on a computer screen, or printed in a 3D model, the prototype should be quickly produced, inexpensive, and a scaled-down version of the final application. Of course, with a community center, sketches or computer models are more realistic than building an actual prototype of a facility.

Next, the team discovered that it's easy to get bogged down in the Ideate, or brainstorming, phase. Coming up with solutions usually presents many options and even uncertainties about which prototype is best. The key is to just plunge into the action and create one to three prototype ideas.

The team also learned not to get attached to prototypes, which is easier said than done with the more time you spend building them. Just like the first step, create a prototype that isn't going to take a long time to develop so you aren't tempted to become emotionally attached and lose your objectives for end user feedback.

Last, the team recognized that it was important to keep prototypes human-centered. It may be easy to create a product from the business' point-of-view, but try to keep the consumers' needs (which you learned about in the Empathize stage) at the center of your prototype designs.

5 CNC Machining Trends To Watch Out For In 2022

Keep an eye out for these trends.

According to Welp Magazine:

Computer numerically controlled (CNC) machining is used for various projects and provides numerous benefits to businesses in different industries. From school children to corporate executives, everyone has encountered devices created using CNC machining. As a matter of fact, the creation of most devices these days involves this kind of machining.

Basically, CNC machining uses computer-numerical control to run machine parts, such as mills, shapers, grinders, routers, and lathes. Compared to some machining forms, CNC machining doesn’t require a human operator.

Since it runs under the control of computers, CNC machining can produce complex and precise parts in a short time. This enables businesses to produce parts faster, maximizing production and reducing time to market.

In a history of CNC machines, it has been nearly 70 years since companies used them. At present, there are many CNC machines in the market designed to meet the growing demands of various companies. If you’re using or planning to invest in CNC machines in the future, here are the CNC machining trends to watch out for in 2022:

1. CNC Robots

CNC robots are one of the trends you should watch for in the CNC machining industry. Due to the ability to interact with people, CNC robotics is a promising trend as it may provide automation for dangerous or difficult tasks on the machine shop floor.

The introduction of artificial intelligence (AI) in different types of precision CNC machining has increased their use with feedback systems and vision sensors. It has also enabled predictive maintenance and adjustments during processing when the sensors on milling machines may change proximity or speed to the cutting surface based on the provided feedback. It has led to more opportunities for longer machine life, better quality, speed of production, etc.

2. Greater Accessibility Of Computer-Aided Design And Manufacturing (CAD/CAM) Software

In today’s modern world, CAD/CAM technology is more accessible than ever, and companies can avail of it at lower prices. Developers of such tools are making user-friendliness a priority. There’s also a growing community of designers and programmers working to make the technology as accessible as possible.

The availability of cloud computing resources and the increasing power of computers also means that designers don’t require high-powered computers to design various parts for CNC machining. Combined with some productivity-boosting strategies, those tools can make every CNC machine more efficient and maximize returns for designers.

The increased accessibility of CAD/CAM can unlock new benefits for businesses and individual designers who may have needed the assistance of bigger manufacturers in the past. Such changes are also part of a broader trend in the world of computer-aided engineering. Over time, computational fluid dynamics (CFD), finite element analysis (FEA), and simulation software will also be more accessible to companies and designers.

3. New Industrial Internet Of Things (IIoT) Devices

New IIoT devices make it easier for companies to network CNC machines and various manufacturing equipment. Such devices that use the internet to receive and send data can allow new features for CNC machines like remote operations monitoring.

The new devices also use IIoT sensors to track the operational parameters of CNC machines. Over time, it’s possible to use gathered data to make predictive models that forecast when devices fail or require maintenance. This approach may help companies improve their maintenance schedule. In addition, it may come in handy in extending the lifespan of CNC machines and allow companies to enjoy savings on maintenance.

4. Multiple Axis Machining

The concept of moving drills plus moving beds created several innovative new approaches to CNC machining when automation was introduced as 3-axis machining. This became a reality with today’s advanced programming machines and technology.

In fact, 4- and 5-axis machines were made and have been in the market for years. However, it’s only recently that such machines have become affordable and available for the whole industry.

At present, 6-axis machines are advancing CNC machining capabilities even more. As more clients demand intricate designs and tighter tolerances, the rise of multiple axes CNC machining will continue this 2022.

5. The Increase Of Manufacturing-As-A-Service (MaaS)

The CNC industry has tapped into MaaS over the past several years, but it’ll continue to grow in 2022. It accomplishes manufacturing through the use of networked resources. The cost of operating and maintaining the CNC equipment is spread across users who need the service.

The primary advantage of Manufacturing-as-a-Service platforms is that businesses can be more productive, enjoy savings, and be agile. The impact of the pandemic will spur businesses to look for other supply chain networks with MaaS. These days, most organizations would want to avoid any disruption in the supply chain, and having an extensive supply chain network may future-proof them on whatever comes next.

Conclusion

New challenges for businesses will likely lead to more innovation in CNC machining for the next few years. The above trends reflect the current market needs and help companies stay ahead of the curve. To know which CNC machine is suited for your business, make sure to take note of the current trends to get the best value for investment.