What is Prototyping? Prototyping Types and Process

According to Creately:

What is a Prototype?

A prototype is a model version of a product. It’s used as an early, inexpensive sample of a product that helps to test its features or identify defects so improvements can be made to its final version.

Prototypes provides the opportunity to gather valuable feedback from stakeholders, partners or customers about the product. This information can be used to build a product that meets their requirements.

Why is Prototyping important?

- Collect feedback from users/ stakeholders about the functionality of the product before the public release

- Reveal areas for improvement and help identify faults and usability issues before the public release. Help reduce unnecessary costs.

- Improve team efficiency and collaboration

- Allow the user to interact with a working model of their product

- Help convert an abstract idea into a tangible product in a cost-effective way

- Identify if your product idea is a weak one and cost you heavily before actually moving forward with it

Prototyping Types

Prototyping methods and prototyping techniques can be categorized as low-fidelity prototypes and high-fidelity prototypes.

Based on the resources available to you and the purpose for prototyping, the prototyping method you choose can be either be low-fidelity or high-fidelity.

Low-Fidelity Prototypes

Low-fidelity prototypes represent a simple and incomplete version of the final product. In a low-fidelity prototype, not all visual features and content elements are conveyed.

While it doesn’t take much time or effort to translate a broad concept to a low-fidelity prototype, it can be used to gather user feedback during the early stage.

Low-fidelity prototyping methods

Wireframes

Wireframes are used to represent the basic structure of a website/ web page/ app. It serves as a blueprint, highlighting the layout of key elements on a page and its functionality.

With Creately, you can create clickable wireframes by adding links to the wireframe elements, that will allow your users to navigate from one interface to the other.

Storyboards

Storyboards are another low-fidelity prototyping method that helps visualize the user’s experience in using your product or how the user would interact with your product.

Diagrams

There are multiple diagram types that can help you visualize different aspects of a product, which can in turn help you optimize your prototype.

- Mind maps can help visualize the structure of a system. You can use it to develop the idea in your head and identify the different elements of your product.

- Customer journey maps can help you understand how the customers would interact with your product across various touchpoints. Like with storyboards, customer journey maps will help you develop an empathetic understanding of the user.

- Flowcharts can be used to visualize user flows or system flows

Animation

You can use animation to visualize how your product works.

For example, if it is a mobile app, you can animate how a user would navigate from one screen to the other. This will help the stakeholders or users get an idea about the functionality of the product.

High-Fidelity Prototypes

Compared to low-fidelity prototypes, high-fidelity ones are more interactive and highly functional. They represent something that is closer to the real product with most of the design elements developed.

High-fidelity prototyping methods

Interactive UI Mockups

A UI mockup is a more fleshed-out version of the wireframe. It represents the color schemes, typography and other visual elements that you have chosen for the final product.

Using the Creately UI mockup tool, you can create navigable UI mockups by linking the different design elements to other UI mockups representing various pages of your website.

The Creately Viewer will allow your users/ stakeholders to navigate through the linked pages and get a closer-to-real user-experience.

Physical Models

If the final product is a physical one, you can use different materials to create a model that represents the final look, shape and feel of the product. You can use materials such as cupboards, rubber, clay etc. here.

Wizard of OZ Prototyping

This is a type of prototype with faked functions. This means when a user interacts with the product, the system responses are generated by a human behind the scene rather than by a software or code.

This prototyping technique allows you to study the reaction of the user at a lesser cost.

Prototyping Process

Prototyping is the 4th step of the design thinking process.

Before you determine how you should go about the prototyping process, you have to have identified the users, defined their problem, and brainstormed and selected a proper solution in the form of a product or service.

Listed below are the steps in the prototyping methodology.

Identify Obstacles

Start by brainstorming with your team to identify any obstacles that may delay or block your prototyping or product designing process. Having these identified prior to designing will allow you to take precautions.

Select the Features

You prototype won’t be able to represent all the product features, therefore you might want to select the key features that will help you gather as much feedback from the user as possible.

Sketch Your Design

You can do this on a piece of paper or a diagramming tool like Creately which provides complete libraries for wireframes, UI mockups, flowcharts, mind maps etc.

Share Your Design

Share your design with partners, stakeholders etc. Ask for their feedback and mark where you need to make modifications to the design based on their requirements.

Continue to Develop

Apply changes and develop your prototype by adding more features. Once it’s ready, you can share it with your stakeholders, partners, users etc. again for their feedback.

What’s Your Favorite Prototyping Method?

In this guide we have covered what is prototyping, prototyping types, prototyping process and prototyping methods.

Prototyping your product before its big release can effectively save you from potential disasters. Any other prototyping technique that you use, do share them with us in the comment section below.

Did you check out our post on requirements gathering techniques? You might want to be aware of these if you are developing a product.

What is CNC Machining? | Definition, Processes, Components & More

According to Thomas Net:

What is CNC Machining?

CNC 101: The term CNC stands for 'computer numerical control', and the CNC machining definition is that it is a subtractive manufacturing process that typically employs computerized controls and machine tools to remove layers of material from a stock piece—known as the blank or workpiece—and produces a custom-designed part. This process is suitable for a wide range of materials, including metals, plastics, wood, glass, foam, and composites, and finds application in a variety of industries, such as large CNC machining, machining of parts and prototypes for telecommunications, and CNC machining aerospace parts, which require tighter tolerances than other industries. Note there is a difference between the CNC machining definition and the CNC machine definition- one is a process and the other is a machine. A CNC machine (sometimes incorrectly referred to as a C and C machine) is a programmable machine that is capable of autonomously performing the operations of CNC machining.

Subtractive manufacturing processes, such as CNC machining, are often presented in contrast to additive manufacturing processes, such as 3D printing, or formative manufacturing processes, such as liquid injection molding. While subtractive processes remove layers of material from the workpiece to produce custom shapes and designs, additive processes assemble layers of material to produce the desired form and formative processes deform and displace stock material into the desired shape. The automated nature of CNC machining enables the production of high precision and high accuracy, simple parts and cost-effectiveness when fulfilling one-off and medium-volume production runs. However, while CNC machining demonstrates certain advantages over other manufacturing processes, the degree of complexity and intricacy attainable for part design and the cost-effectiveness of producing complex parts is limited.

While each type of manufacturing process has its advantages and disadvantages, this article focuses on the CNC machining process, outlining the basics of the process, and the various components and tooling of the CNC machine. Additionally, this article explores various mechanical CNC machining operations and presents alternatives to the CNC machining process.

At a glance, this guide will cover:

Overview of CNC Machining Process

Types of CNC Machining Operations

CNC Machining Equipment and Components

CNC Machining Materials

CNC Size Considerations

Alternatives to Using a CNC Machine

History of CNC Machining

Are you between jobs right now or an employer looking to hire? We've got you covered with our in-depth collections of resources for industrial job seekers and employers looking to fill roles. If you have an open position, you can also fill out our form for a chance to have it featured in the Thomas Monthly Update newsletter.

Overview of CNC Machining Process

Evolving from the numerical control (NC) machining process which utilized punched tape cards, CNC machining is a manufacturing process which utilizes computerized controls to operate and manipulate machine and cutting tools to shape stock material—e.g., metal, plastic, wood, foam, composite, etc.—into custom parts and designs. While the CNC machining process offers various capabilities and operations, the fundamental principles of the process remain largely the same throughout all of them. The basic CNC machining process includes the following stages:

Designing the CAD model

Converting the CAD file to a CNC program

Preparing the CNC machine

Executing the machining operation

CAD Model Design

The CNC machining process begins with the creation of a 2D vector or 3D solid part CAD design either in-house or by a CAD/CAM design service company. Computer-aided design (CAD) software allows designers and manufacturers to produce a model or rendering of their parts and products along with the necessary technical specifications, such as dimensions and geometries, for producing the part or product.

Designs for CNC machined parts are restricted by the capabilities (or inabilities) of the CNC machine and tooling. For example, most CNC machine tooling is cylindrical therefore the part geometries possible via the CNC machining process are limited as the tooling creates curved corner sections. Additionally, the properties of the material being machined, tooling design, and workholding capabilities of the machine further restrict the design possibilities, such as the minimum part thicknesses, maximum part size, and inclusion and complexity of internal cavities and features.

Once the CAD design is completed, the designer exports it to a CNC-compatible file format, such as STEP or IGES.

CNC Machining Tolerances Tables

When specifying parts to a machine shop, it's important to include any necessary tolerances. Though CNC machines are very accurate, they still leave some slight variation between duplicates of the same part, generally around + or - .005 in (.127 mm), which is roughly twice the width of a human hair. To save on costs, buyers should only specify tolerances in areas of the part that will need to be especially accurate because they will come into contact with other parts. While there are standard tolerances for different levels of machining (as shown in the tables below), not all tolerances are equal. If, for example, a part absolutely cannot be larger than the measurement, it might have a specified tolerance of +0.0/-0.5 to show it can be slightly smaller, but no larger in that area.

Table 1: Linear Tolerances in CNC Machining

Table 2: Angle Tolerances in CNC Machining

| Dimension Range (mm) | Fine (F)

+/- |

Medium (M)

+/- |

Coarse (C)

+/- |

Very Coarse (V) +/- |

| 0-10 | 1o | 1o | 1o 30’ | 3o |

| 10-50 | 0 o 30’ | 0 o 30’ | 1o | 2o |

| 50-120 | 0 o 20’ | 0 o 20’ | 0 o 30’ | 1o |

| 120-400 | 0 o 10’ | 0 o 10’ | 0 o 15’ | 0 o 30’ |

| 400 | 0 o 5’ | 0 o 5’ | 0 o 10’ | 0 o 20’ |

Table 3: Radius and Chamfer Tolerances in CNC Machining

| Dimension Range (mm) | Fine (F)

+/- |

Medium (M)

+/- |

Coarse (C)

+/- |

Very Coarse (V) +/- |

| .5-3 | .2 | .2 | .4 | .4 |

| 3-6 | .5 | .5 | 1 | 1 |

| 6 | 1 | 1 | 2 | 2 |

CAD File Conversion

The formatted CAD design file runs through a program, typically computer-aided manufacturing (CAM) software, to extract the part geometry and generates the digital programming code which will control the CNC machine and manipulate the tooling to produce the custom-designed part.

CNC machines used several programming languages, including G-code and M-code. The most well-known of the CNC programming languages, general or geometric code, referred to as G-code, controls when, where, and how the machine tools move—e.g., when to turn on or off, how fast to travel to a particular location, what paths to take, etc.—across the workpiece. Miscellaneous function code, referred to as M-code, controls the auxiliary functions of the machine, such as automating the removal and replacement of the machine cover at the start and end of production, respectively.

Once the CNC program is generated, the operator loads it to the CNC machine.

Machine Setup

Before the operator runs the CNC program, they must prepare the CNC machine for operation. These preparations include affixing the workpiece directly into the machine, onto machinery spindles, or into machine vises or similar workholding devices, and attaching the required tooling, such as drill bits and end mills, to the proper machine components.

Once the machine is fully set up, the operator can run the CNC program.

Machining Operation Execution

The CNC program acts as instructions for the CNC machine; it submits machine commands dictating the tooling’s actions and movements to the machine’s integrated computer, which operates and manipulates the machine tooling. Initiating the program prompts the CNC machine to begin the CNC machining process, and the program guides the machine throughout the process as it executes the necessary machine operations to produce a custom-designed part or product.

CNC machining processes can be performed in-house—if the company invests in obtaining and maintaining their own CNC equipment—or out-sourced to dedicated CNC machining service providers.

Types of CNC Machining Operations

CNC machining is a manufacturing process suitable for a wide variety of industries, including automotive, aerospace, construction, and agriculture, and able to produce a range of products, such as automobile frames, surgical equipment, airplane engines, gears, and hand and garden tools. The process encompasses several different computer-controlled machining operations—including mechanical, chemical, electrical, and thermal processes—which remove the necessary material from the workpiece to produce a custom-designed part or product. While chemical, electrical, and thermal machining processes are covered in a later section, this section explores some of the most common mechanical CNC machining operations including:

Drilling

Milling

Turning

CNC Drilling

Drilling is a machining process which employs multi-point drill bits to produce cylindrical holes in the workpiece. In CNC drilling, typically the CNC machine feeds the rotating drill bit perpendicularly to the plane of the workpiece’s surface, which produces vertically-aligned holes with diameters equal to the diameter of the drill bit employed for the drilling operation. However, angular drilling operations can also be performed through the use of specialized machine configurations and workholding devices. Operational capabilities of the drilling process include counterboring, countersinking, reaming, and tapping.

CNC Milling

Milling is a machining process which employs rotating multi-point cutting tools to remove material from the workpiece. In CNC milling, the CNC machine typically feeds the workpiece to the cutting tool in the same direction as the cutting tool’s rotation, whereas in manual milling the machine feeds the workpiece in the opposite direction to the cutting tool’s rotation. Operational capabilities of the milling process include face milling—cutting shallow, flat surfaces and flat-bottomed cavities into the workpiece—and peripheral milling—cutting deep cavities, such as slots and threads, into the workpiece.

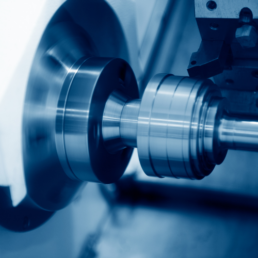

CNC Turning

Turning is a machining process which employs single-point cutting tools to remove material from the rotating workpiece. In CNC turning, the machine—typically a CNC lathe machine—feeds the cutting tool in a linear motion along the surface of the rotating workpiece, removing material around the circumference until the desired diameter is achieved, to produce cylindrical parts with external and internal features, such as slots, tapers, and threads. Operational capabilities of the turning process include boring, facing, grooving, and thread cutting. When it comes down to a CNC mill vs. lathe, milling, with its rotating cutting tools, works better for more complex parts. However, lathes, with rotating workpieces and stationary cutting tools, work best for faster, more accurate creation of round parts.

Table 1 – Characteristics of Common CNC Machining Operations

|

Machining Operation |

Characteristics |

|

Drilling |

|

|

Milling |

|

|

Turning |

|

CNC Metal Spinning

Close cousins to lathes, CNC spinning lathe machines involve a lathe set with a blank (a metal sheet or tube) that rotates at high speeds while a metal spinning roller shapes the workpiece into a desired shape. As a “cold” process, CNC metal spinning forms pre-formed metal—the friction of the spinning lathe contacting the roller creates the force necessary to shape the part.

How Does a Swiss Machine Work?

Swiss machining, also known as swiss screw machining, uses a specialized type of lathe that allows the workpiece to move back and forth as well as rotate, to enable closer tolerances and better stability while cutting. Workpieces are cut right next to the bushing holding them instead of farther away. This allows for less stress on the part being made. Swiss machining is best for small parts in large quantities, like watch screws, as well as for applications with critical straightness or concentricity tolerances. You can find out more about this topic in our guide on how swiss screw machines work.

How Does a 5 Axis CNC Machine Work?

5 axis CNC machining describes a numerically-controlled computerized manufacturing system that adds to the traditional machine tool’s 3-axis linear motions (X, Y, Z) two rotational axes to provide the machine tool access to five out of six part sides in a single operation. By adding a tilting, rotating work holding fixture (or trunnion) to the work table, the mill becomes what is called a 3+2, or an indexed or positional, machine, enabling the milling cutter to approach five out of six sides of a prismatic workpiece at 90° without an operator having to reset the workpiece.

It is not quite a 5-axis mill, however, because the fourth and fifth axes do not move during machining operations. Adding servomotors to the additional axes, plus the computerized control for them – the CNC part –would make it one. Such a machine- which is capable of full simultaneous contouring- is sometimes called a “continuous” or “simultaneous” 5-axis CNC mill. The two additional axes can also be incorporated at the machining head, or split – one axis on the table and one on the head.

CNC Lathe Operator Training

To handle a CNC lathe, a machinist should have completed a set amount of coursework and earned appropriate certification from an accredited industrial training organization. CNC turning machining training programs will usually involve multiple classes or sessions, offering a gradual instruction process broken up into several steps. The importance of adhering to safety protocols is reinforced throughout the training process.

Beginning CNC lathe classes might not include hands-on experience, but they may include familiarizing students with the command codes, translating CAD files, tool selection, cutting sequences, and other areas. A beginner CNC lathe course may include:

Lubrication and scheduling lathe maintenance

Translating instructions into a machine-readable format and loading them into the lathe

Establishing criteria for tool selection

Installing tools and parts for handling the material

Producing sample parts

Later CNC lathe training typically involves actual lathe operation, as well as machine adjustments, program editing, and the development of new command syntax. This type of lathe machine training can include courses on:

Figuring out where edits are needed from comparing sample parts to their specifications

CNC programming edits

Creating multiple cycles of test components to refine the results of edits

Regulating coolant flow, cleaning the lathe, and repair and replacement of tools

5 CNC Machining Trends to Watch in 2022

Curious about trends shaping CNC Machining this year?

According to American Machinist:

With the new year still unfolding, observant manufacturers will want to keep an eye on the world of CNC machining, to be ready for and take advantage of the important developments emerging now. Here’s a closer look at five factors that are shaping the present and future of CNC machining operations.

1. Combining CNC Machining with 3D Printing

There’s no denying that CNC machining and 3D printing are different – one is subtractive, the other is additive. CNC machines cut away unnecessary parts of a workpiece. 3D printing – or additive manufacturing – builds three-dimensional shapes, layer by layer. Machine shops don’t necessarily need to choose just one of these.

A number of manufacturing operations have adopted “hybrid manufacturing” capabilities, combining CNC milling and turning with a direct metal-laser sintering or other additive process. The number of operations looking at how CNC machines and 3D printers can be combined to get projects finished is rising.

When people would ordinarily use injection molding for prototypes, they may discover its more efficient to rely on a 3D printer instead.

When accuracy is a concern, CNC machines can achieve tolerances of up to 0.025 millimeters. However, the accuracy for a 3D printer is typically about 0.1 millimeters – another reason that 3D printers are commonly chosen for making prototypes. After that, a CNC machine can create the product.

Some people may also combine the technologies when they need to produce large volumes of products. CNC machining is a faster production option than using a 3D printer – though in some cases it may be sensible to use a 3D printer to make the parts, then take them to a CNC machine for finish processing. It’s a potentially viable solution for an outcome that is both efficient and accurate.

2. Digital Twins for CNC Machining

People in numerous industrial sector are using digital twins to gather more insight into the performance of their machines and processes. Digital twins are generally much more representative of the respective objects than simulations.

They’re digital versions of physical objects or locations. Moreover, while a simulation usually shows a single process, digital twins are scalable and can give details about several complex processes simultaneously.

One CNC trend to watch this year involves using digital twins during the set-up process to avoid production surprises. There’s already at least one cloud-based product available to link CNC programming to the tools and holders used with each machine.

An operator can enter data about specific CNC machines into the system. Once they do that, the program provides feed, speed, and tooling recommendations accordingly. It’s not yet common to create digital twins for CNC machines. However, this example shows what’s possible and why doing it could become more popular soon.

3. More Preventive and Predictive Maintenance

One CNC machining trend for 2022 involves a move away from reactive upkeep. Deferring the costs of preventive maintenance could sacrifice operational time and cause product waste. On the other hand, staying on top of upkeep helps prolong the machine's service life and enhance performance at peak efficiency.

Artificial intelligence (AI) is becoming more widely used in numerous areas of manufacturing. In 2022, expect to see more attention paid to how AI could help make gains for predictive maintenance for CNC machinery. Whereas preventive maintenance focuses on scheduled appointments to reduce the chances of unexpected breakdowns, predictive maintenance aims to warn operators of issues before they happen.

Researchers recently used AI to measure the quality performance of a CNC milling machine. Their approach used machine learning to detect acoustic signals and match those indicators with excellent or poor-quality performance. The algorithms could suggest when to replace a part, as well as evaluate the amount of wear on a machine. This is an early example from lab tests, but it illustrates why people in the know are starting to think differently about their CNC machine maintenance options.

4. Increased Investments in Automation

Automation is another factor influencing CNC machining operations this year. It has been gaining importance in recent years, and that trend will continue in 2022. As more manufacturers investigate what automation could do for CNC machining, positive results will help the trend gain prominence.

One company offers a camera-controlled robotic cell used to automatically load or unload CNC machines. Customers can then install additional stations to handle turning, measuring, and marking.

In another case, a collaboration between Mitsubishi and AIST resulted in a CNC machine solution that combines automation and AI. It’s an error-correction system that uses AI to estimate discrepancies between a CNC machine’s current position and its command value.

Tests have shown this approach brought a 51% improvement in accuracy compared to non-AI options. This technology can even apply corrections during dynamic machining, saving time while keeping quality high.

5. Flexible Options for Learning CNC Machining

The internet has boosted learning opportunities for people who want to expand their knowledge and skills. Even so, it’s often necessary to blend online learning with hands-on training – and that’s happening with a program from Siemens geared towards people interested in CNC machining.

Siemens provides in-person training for individuals who can access their educational facilities. However, there are also live online sessions and material that people can access through the internet at their convenience.

The broader assortment of CNC training options is something to watch this year, and for the foreseeable future. A 2020 Manufacturing Institute study showed that the average training time spent by current employees at companies was 27.7 hours per year. However, for new employees, the average rose to 42.9 hours annually.

That’s not a survey solely of CNC machinists, but it highlights the need for ongoing training in manufacturing skills. Making it easier for people to get the required training – including through online and in-person training – will make working with CNC machines more feasible and more appealing, which will help to lessen the shortage of candidates for those open jobs and to retain the skilled workers at work now.

An Exciting CNC Trend Outlook – These trends show how shop owners, managers, and operators have much to anticipate regarding CNC machining during the year ahead. Although it is not a comprehensive overview, it highlights the things that will have noticeable impacts this year.

Forging and Casting Components Market Share 2022

Curious about the future of the forgings and castings market?

According to Globe Newswire:

Forging and Casting Components market report is expert study that can deliver you with an elaborate analysis of the Forging and Casting Components. The report covers information about top players, projected size of the market, data and figures to update about where opportunities are in the market, competitor analysis and vendor information. Also, it offers a complete analysis of the key market dynamics, with growth drivers, challenges, restraints, opportunities and trends. Furthermore, receive exact details and statistics associated to Forging and Casting Components market and its key factors such as revenue, growth, compound annual growth, year-over-year developments, consumption, and production.

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons. Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanisms and machines wherever a component requires high strength; such forgings usually require further processing (such as machining) to achieve a finished part. Today, forging is a major worldwide industry.

Casting is a foundry process by which a metal part is produced from a ceramic (investment) mold that has been formed by a disposable (wax or plastic) pattern.They are products using the lost wax process which is a process for producing near-net-shape metal parts. Investment casting process is an industrial process in which high technology waxes are used to form patterns that allow the production of components with accuracy, repeatability, versatility, and integrity in a variety of metals and high-performance alloys.

Today, forging and casting are major worldwide industry.

Competitive Landscape:

Report offers the Forging and Casting Components market competition landscape and a corresponding comprehensive study of the prominent players in this market, include

- Precision Castparts Corp

- Arconic

- Nippon Steel & Sumitomo Metal

- KOBELCO

- Thyssenkrupp

- Aichi Steel

- Eramet Group

- American Axle & Manufacturing Holdings

- Bharat Forge Limited

- Avic Heavy Machinery

- VSMPO-AVISMA

- Allegheny Technologies

- WanXiang

- FAW

- VDM Metals

- Mahindra Forgings Europe

- JSW

- CITIC Heavy Industries

- Scot Forge

- Farinia Group

- Longcheng Forging

- KITZ Corporation

- Tongyu Heavy Industry

- Sinotruck

- Dongfeng Forging

- Jiangsu Pacific Precision Forging

- China National Erzhong Group

- China First Heavy Industries

- Sypris Solutions

- Ashok Leyland Limited (Hinduja Group)

Market Segmentation:

Forging and Casting Components market report delivers study of the key trends in each sub-segment of the worldwide Forging and Casting Components report, with estimates for development at the global, regional and country level and categorized the market based on product type, applications, regions.

Segment by Type

- Forging

- Casting

Segment by Application

- Automotive

- Aerospace

- Agricultural

- General Industrial

- Others

Regional Analysis:

- North America (United States, Canada and Mexico)

- Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

- Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

- South America (Brazil etc.)

- Middle East and Africa (Egypt and GCC Countries)

Years considered for this report:

- Historical Years: 2016-2021

- Base Year: 2021

- Estimated Year: 2022

- Forecast Period: 2022-2027

Detailed TOC of Global Forging and Casting Components Market Outlook 2022

1 Forging and Casting Components Market Overview

1.1 Product Overview and Scope of Forging and Casting Components

1.2 Forging and Casting Components Segment by Type

1.3 Forging and Casting Components Segment by Application

1.4 Global Market Growth Prospects

1.5 Global Market Size by Region

2 Market Competition by Manufacturers

2.1 Global Forging and Casting Components Production Market Share by Manufacturers (2016-2021)

2.2 Global Forging and Casting Components Revenue Market Share by Manufacturers (2016-2021)

2.3 Forging and Casting Components Market Share by Company Type (Tier 1, Tier 2 and Tier 3)

2.4 Global Forging and Casting Components Average Price by Manufacturers (2016-2021)

2.5 Manufacturers Forging and Casting Components Production Sites, Area Served, Product Types

2.6 Forging and Casting Components Market Competitive Situation and Trends

3 Production and Capacity by Region

3.1 Global Production of Forging and Casting Components Market Share by Region (2016-2021)

3.2 Global Forging and Casting Components Revenue Market Share by Region (2016-2021)

3.3 Global Forging and Casting Components Production, Revenue, Price and Gross Margin (2016-2021)

3.4 North America Forging and Casting Components Production

3.5 Europe Forging and Casting Components Production

3.6 China Forging and Casting Components Production

3.7 Japan Forging and Casting Components Production

4 Global Forging and Casting Components Consumption by Region

4.1 Global Forging and Casting Components Consumption by Region

4.2 North America

4.3 Europe

4.4 Asia Pacific

4.5 Latin America

5 Production, Revenue, Price Trend by Type

5.1 Global Forging and Casting Components Production Market Share by Type (2016-2021)

5.2 Global Forging and Casting Components Revenue Market Share by Type (2016-2021)

5.3 Global Forging and Casting Components Price by Type (2016-2021)

6 Consumption Analysis by Application

6.1 Global Forging and Casting Components Consumption Market Share by Application (2016-2021)

6.2 Global Forging and Casting Components Consumption Growth Rate by Application (2016-2021)

Continued…

Expansion of Aerostar in Romulus bringing jobs, has total capital investment of $8.6M

We are super excited to announce that we are expanding again. We are building a brand new 55,000 sq ft facility to house our growing manufacturing needs. Our facility will be located on Northline Road, Romulus, Michigan, next to our headquarter building. Our core values of “Customer Obsession” and “Continuous Improvements” with the mindset of seeing “the glass half empty” has allowed us to grow with our existing, as well as, new customers. We want to thank our hard working employees who exceed our customers’ expectations on a regular basis.

According to News Herald:

The announcement of numerous manufacturing jobs and millions of investment dollars coming to Romulus has many energized.

Aerostar Manufacturing is expanding its operations, making way for the creation of 62 jobs.

Gov. Gretchen Whitmer helped spark the excitement with the announcement of the expansion and job opportunities with the Michigan Economic Development Corp (MEDC).

“This project is a win for southeast Michigan and for the entire state,” said Quentin Messer Jr., CEO of the MEDC and president and chair of the Michigan Strategic Fund. “We’re proud to join our local partners as we celebrate Aerostar’s expansion in Michigan and look forward to working together to grow, add jobs and provide greater opportunity for our friends and neighbors.”

A total capital investment of $8.6 million, supported by a $200,000 Michigan Development Program performance-based grant, is expected to be generated by the expansion.

Sharing in the excitement is state Rep. Alex Garza (D-Taylor), who issued a statement.

“I’m thrilled that Aerostar has opted to expand its operations in Metro Detroit,” he said. “This investment will result in more good-paying jobs for the hardworking people of Michigan and continue to benefit our economy. I look forward to seeing the work Aerostar will do in Metro Detroit and what great economic opportunities come next for our community.”

In her announcement, Whitmer said her administration has been laser-focused on growing Michigan’s economy.

“We’re working hard in a bipartisan fashion to ensure Michigan’s business climate and talented manufacturing workforce can thrive and create more jobs,” she said. “That work paid off over the last year, and my administration added 220,000 jobs to help businesses bounce back.”

She said her administration is celebrating Aerostar’s expansion in the state.

“This is great news for workers, their families, and our economy as we continue putting Michiganders first,” Whitmer said.

Aerostar specializes in Computer Numerical Control machining and assembly for the automotive, heavy truck, defense, aerospace and other key industries and markets. The company currently has 131 employees in Michigan.

Lalit Goel, CEO of the manufacturing company, thanked all involved for helping his business navigate through the steps of the application process in order to obtain various state and local benefits.

The Romulus site got the nod over other competing sites in Indiana and Georgia.

“In the end, it wasn’t just the dollars and cents, but many intangibles like manufacturing infrastructure, trained workforce and being close to many world-class existing and potential customers in Michigan that tipped the scale in Michigan’s favor,” Goel said.

Aerostar is a minority-owned business and more than half of its workforce is from minority or underrepresented communities.

It is growing rapidly and plans to establish a new manufacturing facility in Romulus for light to medium manufacturing, CNC machining, assembly, and other related industrial activities.

The Detroit Region Aerotropolis has approved a 50% property tax abatement in support of the project.

The Aerospace Industry Is Preparing For An Upturn

Following a rough patch for the aerospace industry, the future looks bright.

According to Forbes:

There's no doubt that the Aerospace and Defense industry is strategic to the global economy. Since the first powered flight in 1903, the industry has grown by leaps and bounds. The industry in the U.S. nearly accounted for $909 billion in sales in 2019, while in Europe the total turnover was over 250 billion euros.

While the industry is often known for its cyclicality, 2020 saw the worst downturn in its history. After a decade of continued growth, the aircraft production rate increased year on year to fulfill the growing demand for air travel, reaching the peak in 2018 with a total of 1,606 aircraft delivered from Airbus and Boeing.

The Repercussions Of The Global Pandemic

In 2020, airlines suffered enormous financial hits due to global travel restrictions and various border closures. International flights saw the worst drop of 68% versus domestic flights which suffered a 40% drop. In our analysis, we saw major airlines suffering a 60% drop in revenue compared with 2019, while cargo revenue was up by some 3% on average.

On the manufacturing side, the industry suffered its first crisis in 2019 with the grounding of the B737Max, followed by a 30% reduction in the overall production rate of commercial aircraft from Airbus in 2020 as a result of the Covid-19 crisis.

In a broad market analysis that I conducted, manufacturers globally suffered between a 30% drop and a 50% drop in sales dependent on their customer portfolio, some manufacturers with a larger share of commercial aerospace portfolio saw between a 60%-70% drop.

Defense contracts provided some hedging for suppliers with large defense portfolios, where the majority of defense companies maintained positive growth in 2020. The majority of aerospace suppliers experienced a difficult year, while not all manufacturers were able to turn a positive profit. We calculated an earnings before interest, taxes, depreciation and amortization (EBITDA) margin in 2020 to be on average around 14% of the margins in 2019.

In general, government support schemes coupled with original equipment manufacturers (OEMs) like Airbus that maintained an artificial production rate, provided sensible protection to the supply chain against any major structural disruption. And now, the current question is about the shape of the recovery. The main concern remains as to the ability of those suppliers to ramp up at a steep rate when required to support the recovery.

The Industry Rallies For Recovery

We expect recovery to kick off in the second half of 2021. And it might take a few years, perhaps until 2024, for air travel to reach the global level of 2019. The next four to five years will see significant transformation across the supply chain, technology development and in the way we fly and transport goods by air.

According to various forecasts by Cirium and Eurocontrol monitor, domestic and leisure travel will be the quickest to recover, signaling that the demand for air travel is still healthy. However, international travel and business travel recovery will take longer to recover to 2019 levels. In our analysis and based on data that we obtained from sources such as S&P Cap IQ and Market Intelligence, we expect domestic flight and low-cost carrier revenue for 2021 to grow by 90% year-over-year.

Manufacturers and suppliers are preparing for the first ramp-up in production of single-aisle aircraft in Q3 by OEMs such as Airbus. We anticipate seeing on average an 11% increase in revenue across the supply chain compared with 2020. Most suppliers who suffered losses in 2020 are expected to return to positive profits this year. Recovery is expected to strengthen in 2022, signaling more consolidation and more research and development (R&D) spending to mature the necessary technology for the next generation aircraft program planned for 2025.

If we look at the deal activity and consolidation throughout the industry, based on data we obtained from S&P cap IQ and based on our analysis, global deal activities volume was healthy, with the U.S. seeing a growth in the deal volume. Meanwhile, in Europe, government support and measures taken by Airbus slowed deal activities. Across the globe, the average deal size in 2020 was about half the average in 2019, signaling smaller transactions and consolidation among fragmented sectors of the industry.

Looking Ahead To The Future

We expect this trend to continue in 2021 and 2022, with more restructuring and divestiture carve-outs from larger corporates taking place. Industry attractiveness and valuation multiples continue to be at healthy levels despite the severe industry impact, signaling investor's confidence in the industry.

During my analysis work, I interviewed more than 20 executives, CEOs and private equity investors across the industry in Europe and the U.S., and I asked them about their priorities and their prospects for the industry. Based on my analysis of their responses, here are some of the top tips for doing business in the aerospace industry:

• Manage cash and liquidity: Focus on keeping operations running and maintaining relationships with customers and suppliers — on time, on cost and on quality delivery all remain critical.

• Assess and review your product portfolio: Consider potential alternative customers/sectors for your existing products.

• Review people strategy: Consider how to retain talent, as well as keeping teams engaged, developed and motivated.

• Review your strategy beyond 2023: Identify areas to inject capital, as well as seek out potential mergers and acquisitions (M&A) opportunities.

On the whole, the outlook for the industry rebound is extremely positive. The high barriers to entry coupled with long-term contracts offer a way through any potential crisis. The road to pandemic recovery is a bumpy one, with the vaccine rollout proving to be challenging and several questioning the longevity of the vaccine and veracity of the different viral strains.

We are more likely to see a more staged recovery over the next four years rather than a quick return to form. I firmly believe that more opportunities lie ahead — that we are over the worst and upturns should start soon. There is no shortage of capital and certainly no shortage of good assets.

Suppliers and companies in the industry should be thinking about growth and start planning now. It is complex and risky but highly rewarding when carefully executed.

CNC Machining Industry Trends for 2022 and Beyond

What trends will be shaping the CNC machining industry this year?

According to Let's Do Startup:

The new year brings a novel chance to reflect upon the factors that influenced the current manufacturing environment and consider the forces that will shape the manufacturing industry in the new 365 days and beyond.

In the CNC machining industry, regardless of what our plans and strategies were for the past two pandemic years, now more than ever before, there’s an evident need for pushing new technology solutions even further as the industry needs to react and implement remote work and automate essential processes in order to stay functional and open. Put differently, the CNC machining industry had to grow and adapt quickly to confront supply chain problems and adapt to shifting consumer demands by embracing new technologies and tools.

And while the industry has followed a fairly steady path since the mid-1900s, like with many other sectors, recently, the Industrial Internet of Things continues to bring new challenges and opportunities for CNC manufacturers. In addition, attending trade shows to find new partners and secure the production of new products has been limited due to government travel restrictions and the need for physical separation, making things more difficult for CNC machining companies to acquire new clients on the open market.

However, progress always finds a way, and the CNC machining industry is one of the most progressive manufacturing sectors in today’s world. With these things in mind, here are the top 4 CNC machining industry trends for 2022 and beyond.

Shorter New Product Development Cycles

In the years to come, companies will continue to search for ways to shorten their product development cycles to grow their business further and beat their market rivals. Companies focused on top-line revenue growth can achieve this goal by launching new products in faster product development cycles thanks to rapid prototyping services to propel speedier growth and gain a more significant market share.

For that reason, we can expect CNC engineers and designers to eagerly adopt new tools, technologies, and processes like rapid prototyping to keep up with their desired accelerated product launches.

The Emergence of Sustainable Solutions Will Continue to Grow

With a growing appetite for sustainably produced products among consumers, CNC companies will need to begin measuring and reducing carbon emissions created by their manufacturing processes and supply chains. Corporate responsibility, consumer demand, and government regulations will continue to contribute to CNC machining services’ new or renewed efforts to reduce carbon emissions.

In 2022 and beyond, all manufacturing companies will use more accessible manufacturing and supply data chains to evaluate their products’ carbon footprints better and search for new opportunities to manufacture and transport their goods more sustainably.

6-Axis CNC Machining Will Thrive in 2022

Although they first emerged in 2019, we predict that 6-axis CNC machines will become the next big thing in CNC manufacturing in 2022. In the end, the more axis there are, the quicker the production time will be, which goes hand in hand with the shorter product development cycles we covered earlier in this article.

Currently, most CNC machines provide three or five-axis support, which means that the machine can manufacture a design in three dimensions (X, Y, and Z), while five-axis CNC machines use an additional spindle to work with an extra two axis. In addition, the six-axis CNC machines allow for a further rotation around the Z-axis, making for rapid cut times.

In 2022 and beyond, we can foresee that more and more CNC fabricators and shops will turn their attention to six-axis CNC machinery, which will prove ideal for high-precision production of parts like automotive components or aerospace parts that demand the highest precision possible.

MaaS Will Keep Gaining Momentum

MaaS, or manufacturing as a service, made its way into the CNC machining only recently, but expect it to gain wider acceptance as we advance in time. In a few words, MaaS uses networked resources to achieve manufacturing tasks, as CNC machines and tooling are placed in one central location. At the same time, the costs of operation, repairs, and annual maintenance are spread among the service’s subscribers.

Furthermore, MaaS can provide companies additional flexibility, superior productivity, agility, and cost savings through reduced labor expenses. Therefore, as the fallout from the pandemic persists, assume that companies that want to lessen their expenditures and operate on tight budgets to at least explore the possibility of subscribing to a CNC-powered MaaS service.

Final Thoughts

Irrespective of the past two and half year’s unanticipated market interruptions because of the Covid-19 pandemic, the CNC machining industry will continue to be at the forefront of global manufacturing. For companies to become more flexible and adaptable in these uncertain times, they will have to find ways to shorten the development cycles of their new product designs and come up with sustainable solutions for their manufacturing efforts.

In addition, CNC manufacturers will become to incorporate six-axis CNC machining within their shops or subscribe to the growing MaaS CNC services that have emerged in recent years to cut the costs tied to the physical keeping and operation of the machines.

CNC Machines And The Automotive Industry: A Variety Of Applications

The automotive industry uses CNC machining for a variety of applications.

According to Boss Magazine:

Since Henry Ford invented the assembly line to produce Ford Motors, there has been a constant striving to make the process as efficient as possible. Technology has increased an incredible amount in the subsequent decades.

These days, advances in CNC machining expertise have led to an increase in innovations in automotive design and performance. There are a few different applications of CNC machining which have led to these innovations.

Increased production speed

Much of the machining process is automated which increases production speed. Before the advances in technology, many of the machines were quite labor-intensive. For instance, the Internet of Things has helped to shave seconds off of each cycle of an order. A sensor calculates cycle time much more accurately and in real-time. Previously, engineers had to calculate cycle times by dividing the hypothetical machining time by the number of cycles. This was not at all accurate.

This saved time can help to ramp up production when there are tens or even hundreds of thousands of pieces being manufactured.

Automation

Automation is streamlining just about every aspect of the manufacturing process. CNC machines are built for automation so there is less labor needed to run the machine. Since accuracy is vital in the making of precision auto parts, automation is the only way to go.

Swiss CNC machines are able to hold the tolerance to less than a few microns. By using automation, this accuracy can be maintained with the operator there to simply make sure that programmed parameters are set. The other workers in the machine shop are able to dedicate themselves more to the design and operations type of tasks rather than running the machines.

Customization

Customization of machined parts generally comes with a long lead time. However, when using CNC machines, there is a much shorter lead time involved. When dealing with automotive frames, this is especially important as the customization is not only good for lead times but also accuracy in staying true to the design.

There are many different types of specialized CNC machines so there is an endless possibility of customizations that can be done. 5 axis machines provide a wide array of cutting tool angles that allow for a high tolerance even with highly complex shapes.

People looking to restore vintage vehicles often turn to CNC machining for this reason. Parts that are no longer manufactured can have a second life in this way.

Prototyping

Just about every piece of a car has had a prototype made before production begins in earnest. From headlight covers to gearboxes, a prototype piece is an invaluable process that helps to spot design defects or poor integration with other parts. This saves a lot of time and money during the manufacturing phase.

Since it is not a big problem to reconfigure the specs on a piece, CNC machines prove to be ideal to make prototypes and then reconfigure when necessary to switch to the production of thousands of the piece.

Global CNC Machine Market 2022 Research Scope, Trends and Challenges

Consider this report on the future of the CNC market.

According to MarketWatch:

The latest research document published through MarketsandResearch.biz, the Global CNC Machine Market is predicted to witness significant increase all through the forecast length 2022 to 2028. The research report gives marketplace share analysis in terms of quantity and sales. The document includes a profound analysis of current developments, development opportunities, challenges, and challenges.

This report gives an correct and up-to-date picture of the enterprise and gives the necessary records approximately the various factors influencing the adjustments in it thru meticulous studies and correct data. Important industry developments, market size, market proportion estimates, and profiles of the top industry competitors are all discussed on this report.

The document gives a thorough investigation of the global CNC Machine market, along dropping mild on predicted upcoming developments that can play a crucial function further in market improvement. A wide list of producers are considered in the survey with company profiling of

- Yamazaki Mazak

- DMG Mori Seiki

- TRUMPF

- AMADA

- Okuma Corporation

- MAG

- JTEKT Corporation

- Schuler

- GF Machining Solutions

- Haas Automation

- Emag

- Hyundai WIA

- Doosan Infracore

- Makino

- INDEX

- Bystronic

- Korber Schleifring

- Gleason

- KOMATSU NTC

- GROB

- Hurco

- HERMLE

- Hardinge Group

- Chiron

- TORNOS

- Schutte

- NAGEL

- MHI

- SAMAG

- SMTCL

- Qinchuan

- KMTCL

- DMTG

- HDCNC

- Yunnan Xiyi

- Shandong FIN

- Yuhuan CNC

- Qinghai Huading

- TONTEC

The countries included in the market document are:

- North America (United States, Canada and Mexico)

- Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe)

- Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia)

- South America (Brazil, Argentina, Colombia, and Rest of South America)

- Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

The study consists of information on market segments such as

- Machinery manufacturing

- Automobile

- Aerospace & Defense

- Others

Product gives, revenue analysis, production capabilities, gross margins, and several other important factors that influence a agency’s profitability in the market also are included. Market segment by type, the product is divided into

- CNC Lathe

- CNC Milling Machine

- CNC Grinding machine

- Others

Some of the Major Issues Addressed in the Report:

- What market segments are attracting the most attention?

- What are the enterprise dangers and implications of the current scenario for market increase and forecasting?

- Who are the major contributors in the market, and how are they facing numerous challenges?

Why The Change Of Focus Of Aerospace Industries To CNC Machining

Over recent years, there has been a shift in focus toward CNC machining, but why?

According to Quantum Marketer:

Different classes of materials are suitable for making parts used in the aerospace industries. Parts used for aerospace machines have a huge requirement.

Aside from the inherent properties of the material used in making them e.g., strength, durability, and lightweight, highly precise manufacturing processes must be used in their manufacture.

There are many manufacturing processes used in making such parts. However, CNC machining stands out due to its high precision and accuracy.

Consequently, there is a change in focus of aerospace industries to CNC machining and high use of CNC parts in making aerospace machines.

High precision and accuracy are not the only reasons for the change in focus, and this article introduces several reasons that called for the switch of attention to CNC machining in aerospace industries.

Why Does CNC Machining Matter In The Aerospace Industry?

The importance of CNC machining in the aerospace industry will be discussed under two broad categories.

The first category is based on the view of aerospace industries, while the second category will be based on the view of CNC machining

From The View of Aerospace Industry

Not all kinds of materials and products are suitable for making parts used in aerospace industries, as such materials must meet up to certain standards.

Below are a few things to note about the aerospace industry and why they shifted to CNC machining.

Tight Requirements for Aerospace Industries

Materials suitable for making products and parts of aviation industries must be of top quality with high performance and durability.

Aside from that, such material requires tolerance and a high level of precision and accuracy.

This is where CNC machining comes in as it is one of the most used manufacturing processes in various industries.

Features Of Aerospace Products

As said before, aerospace products must have certain properties that make them highly suitable for the industry.

These attributes are responsible for the change in focus of the industries to the use of CNC machined parts.

Below are the features of aerospace products:

Lightweight

Aerospace products must be lightweight. Whether plastics or metals, their lightweight might indicate softness which makes CNC machining a very good option for making them.

Precision and Accuracy

CNC machining is arguably the most precise and accurate manufacturing process you can use.

As aerospace products must be highly precise and accurate to reduce error in product making which might lead to risk, CNC machining is the perfect option.

The process involves the use of computers, which limits human interference and reduces the margin of errors.

Durability

This does not contribute directly to the use of CNC machining by aerospace industries. However, aerospace products must be highly durable.

Examples of such materials are titanium, aluminum, and some hard polymer plastics. Their use will ensure that they serve you for a long time.

High performance and efficiency

Aerospace products made from titanium and other materials are high-performance metals. They are difficult to process by other means making CNC machining the perfect option.

From The View of CNC Machining

What makes CNC products ideal for the aerospace industry? What are the features of the CNC machining process that makes it suitable for aerospace industries?

Understanding the answers to these questions will further show you why the aerospace industry is now considering using precision CNC machining services for making parts used in their machines.

Shorten Product Development Cycle

CNC machining has a fast production process, unlike other manufacturing processes such as 3D printing and injection molding.

Also, tooling is minimal. Therefore, after making the CAD model, the computer takes charge of the manufacturing process.

A Shortened product development cycle ensures that the aerospace industry can order and receive products in a short amount of time.

High Precision

CNC machines have a very low margin of error. Therefore, the final products are precise, i.e., alike in terms of dimension, size, etc., and accurate, i.e., similar to the intended design in terms of dimension, size.

Machinability (titanium)

Titanium is an important material used in aerospace industries due to its durability and lightweight.

Although it is highly durable, strong, and resistant to abrasion and heat, machining is very difficult, not possible. Therefore, this metal requires some level of expertise.

Before most precision CNC machining services work with titanium, they map out the whole machining process to the last detail in terms of tools and technology.

This will allow them to deliver in terms of quality.

Application of CNC Machining in The Aerospace Industry

The aerospace industry comprises different types of aircraft and technologies aimed at transportation and research.

CNC machining has a huge application in the aerospace industry due to its features not being available in other prototyping methods, like 3D printing.

Below are a few applications of CNC machining:

- Complex design fabrication

Some aerospace parts are very complex. For example, NASA’s Orion bulkhead developed to ensure safety has a dome structure and pockets normally to its surface. Making these components requires extremely tight tolerances. Therefore, CNC machining is the ideal process. For example, 5-axis CNC milling machines are suitable machines for making complex parts used in the aerospace industry. These machines are suitable as they can reach angles not feasible for 3- or 4-axis machines.

- Lightweight Metal Components

Metals such as aluminum and titanium have huge strength and durability, and they dominate the aerospace industry due to their lightweight. This is because their use reduces fuel consumption while boosting aircrafts’ overall performance.

Machining these metals is time-consuming, and CNC machining benefits the aerospace industry as it is compatible with a wide variety of materials.

- CNC rapid prototyping

Research and development are important in any industry, and for the aerospace industry, CNC machining is at the forefront. You can expect a short prototyping production cycle employing CNC machining. Therefore, aerospace engineers can easily develop, edit, and test new prototypes in real-time while complying with AS9001 and ISO 9001:2015 standards.

- Components in Aviation

Every component used in an aircraft’s construction requires a high level of precision and accuracy. CNC machining is crucial in making the interior part of an aircraft, such as the engine, cockpit, and navigation system. Its extreme precision and significance help in ruling out any odds of failure.

Conclusion

Durable materials with high quality, performance, efficiency, and design specification, are key ingredients needed by aerospace industries.

These are features that CNC machining guarantees the industry, which is one main reason for the shift in focus to CNC above all other prototyping methods.

This article introduces the features offered by the manufacturing process and why the aerospace industry is shifting its focus to CNC machining.