How CNC Machining is Impacting Modern-Day Manufacturing? An Expert View

When it comes to modern manufacturing, CNC machining has more of an impact than you might think.

According to Manufacturing Tomorrow:

Regardless of your manufacturing business having its inception only a couple of years back or you being a trained professional, you must be familiar with CNC machining and how it can benefit your business in manufacturing operations.

Almost every manufacturing industry, from automobile production plants to manufacturing musical instruments, employs Computer Numerical Control (CNC) machines.

Operation of CNC Machining

CNC machining is a manufacturing approach dictated by predefined computer codes that guide the functioning of machinery like a grinder, milling, or lathe.

CAM software helps generate these codes using CAD drawings. This software implements a series of codes to regulate all aspects of machining processes. Minimal to no human intervention is necessary to operate CNC machining from feed rate to tool distance.

CNC offers multiple features such as multi-axis capabilities and computer control. For instance, a CNC lathe can operate diversely by doing cuts in circular directions. With several advanced machines like plasma cutters, water jet cutters, and CNC mills, manufacturers can accomplish complex production processes.

The Global Outreach of CNC Machining

Several manufacturing facilities have extensively adopted CNC machining, with its global market hitting worth $70 billion in 2018. This market worth is anticipated to hit $111 billion by 2026, depicting a 6.8% growth in six years.

CNC manufacturing has reduced operating expenses, eliminated errors in manufacturing, and has enabled seamless adoption with the rise of IoT technologies and predictive analytics.

For instance, the automotive sector immensely depends on CNC machining for production due to the increasing demand for spare parts and the necessity for higher precision. As such, the current trends in CNC machining hold great promise for machine shops.

Advantages of CNC Machining

The most prominent advantage offered by these machines is their ability to perform several operations uninterruptedly with no modification settings, thinning out the probability of errors due to human intervention.

Here are some advantages that CNC machining offers in manufacturing, in contrast to traditional and conventional machining process -

Increased Capability

When integrated with advanced design software, CNC machines generate outputs that are irreplicable manual machines. CNC machines can produce the desired size, shape, or texture of components. Best of all, an efficient benchtop CNC mill can yield maximum performance while occupying minimal room space.

Reduced Labor

CNC machining demands a lesser workforce to accomplish the production tasks. One skilled operator can operate most of the autonomous CNC machines, and a single programmer can get them loaded with the required designs.

Resources saved on labor can get passed along to customers, enabling you to achieve competitive leverage.

Uniform Product Delivery

Even the most skilled engineers operating a conventional machine will build components that will differ slightly. With CNC machines, each part is an excellent match to the precise specifications of the prototype.

CNC machines build precise tools and components due to automation and no human intervention, which is susceptible to generating sluggish results.

CNC Machining - Applications and Perks

Here are some applications of implementing CNC machining in the manufacturing process -

Reduced Operating Costs And Maximized Efficiency

The emerging implementation of computer-aided manufacturing (CAM) and computer-aided design (CAD) in prototyping and product design augments manufacturers to deliver high-precision components for various industries.

CNC equipment helps alleviate operating costs, boosts the efficiency of mass production, and builds up its revenue. It also renders precise detailing that manual processes lack and works with the broadest range of components.

CNC machines rarely require service other than to change the cutting implements at specified intervals or slight cleaning. None of the routine maintenance demands professional service, which helps save capital resources.

Enhanced Quality Via Automation

CNC machines render an extraordinary degree of accuracy when constructing complex shapes such as curves or diagonal cuts. This perk has led to an explosive demand for implementing technological advancements of CAD, CAM, and CNC software.

As critical CNC equipment repairs are financially taxing, manufacturers have started utilizing predictive analytics and predictive technology. Such tools are helping companies curb their downtimes because of repairs and ensure a streamlined functioning of processes.

Extensive Demand of CNC Parts

CNC parts enjoy a comprehensive range of applications in every sector and are extremely popular in large-scale industries like aerospace.

This extensive demand is due to their ability to build intricate geometries with ease and high-quality precision. Aluminum is a commonly used material because of its extraordinary mechanical properties.

Enhanced Prototyping and 3D Modelling

Precise modeling and prototyping are pivotal to the realization of the production process. A CNC machine enables you to scan, copy, engineer, and even reverse-engineer components to design innovative and advanced products.

The pace of production of CNC routers and CNC plasmas allows you to speed up project timelines as you swiftly and accurately build realistic prototypes to influence future decision-making.

Final Words

The extensive implementation of CNC machinery across several industries has optimized an enormous range of manufacturing capabilities. It ensures extreme levels of precision, cost-efficiency, equipment safety and enables the mass-production of parts.

As industries embrace industrial automation, CNC machining and tools are helping alleviate costs and boost the production tempo. CNC machining enables small and large businesses to compete and render greater work flexibility with a wide range of materials.

WHAT IS CNC MACHINING?

New to CNC machining? Here is a brief explanation.

According to the Universal Technical Institute:

Have you ever wondered, “What does CNC stand for?” CNC machining, or CNC manufacturing, is a process using computer numerical control (CNC) machines, which are tools such as mills and lathes guided by computer instructions that control the precision of the instruments.

CNC machining enables the creation of parts and components that would usually be impossible to create manually. A single set of prompts fed into a computer can produce complex 3D products. The CNC machine removes material from the base stock piece through drilling, milling, turning or other types of operations to create shapes, angles and the finished product.

The answer to “What is CNC?” is to think about the process as a blending of technology and physical tools. Computers take input from CNC machinists, who translate drawings into a programming language called G-code. The CNC machine then dictates to the tool what speed and movement to follow in order to create the desired part or object.

If you’ve ever wondered “What does CNC stand for?” and are curious what a CNC machinist career looks like, read on.

What CNC Machinists Do

There are many different fields where CNC machinists can work, including automotive, manufacturing, dental, computer part production, aerospace, tool and die making, motorsports, and medical industries. CNC machinists read blueprints and computer-aided manufacturing (CAM) and computer-aided design (CAD) files. They set up and manage CNC machine tool operation. They have to measure and test completed products to ensure they’re perfect. And they modify CNC processes as needed.

Several graduates from the CNC Machining Technology program, a UTI program taught at NASCAR Technical Institute, have gone on to work for Roush Yates Engines. Other CNC machinists have a hand in making joint replacements and other implants for the human body.

CNC machines create large components, like automobile frames and doors, and small parts, like those found on medical devices. CNC machining uses all types of material, from plastics and metals to wood, foam and fiberglass.

CNC machine tools improve automation, making it possible to reduce or eliminate operator intervention for producing quality products. CNC machines are fast and efficient. They reduce the likelihood of mistakes caused by human error or operator fatigue.

CNC machines also provide flexibility. Since they’re run from programs, you simply need to load a new program or add a new prompt to an existing program by revising the code if you want to create a new part. Once the program is verified after you’ve tested it, you can use that program in the future whenever you want to produce the same part.

How Much Do CNC Machinists Make?

According to the U.S. Bureau of Labor Statistics, the national median annual salary for computer numerically controlled tool operators was $41,200 in May 2019.

In this industry, salary depends on several factors, including skill level, experience and specialty. CNC machinists are in high demand, which can potentially open doors to exciting opportunities for those trained in the field. Whether it’s working on military equipment or parts of a car, CNC machinists are needed across a wide variety of industries.

Who Is a Fit for a Career in CNC Machining?

Problem solvers who are mechanically minded may be a fit for CNC machining, since math and communication skills are essential qualities for CNC machinists. CNC machinists must possess strong attention to detail, be able to work autonomously and independently, excel at following directions, and have a grasp of computers in order to be successful.

“Machinists are a little OCD,” says NASCAR Tech instructor Craig Hibdon. “They like to be in control and like to seek perfection. We live in a world of small tolerances.”

CNC instructor Andrew Collier agrees.

“I think the people who tend to make the best machinists are people who like working with their hands but have a great attention to detail,” Collier says. “Quick example: I moved into a new house and was hanging a 60-inch TV on my wall. I finished, and stepped back and said to my wife, ‘That isn't level.’ ”

Collier continues, “My wife says, ‘What do you mean? It looks great,’ as I walk over to the TV with a tape measure. I exclaim, ‘No, this side is an eighth of an inch higher.’ That is most machinists I know in a nutshell.”

No machines are perfect. CNC machinists must be prepared to troubleshoot problems as their machines operate. From start to finish of a project, there are always important details to monitor. Since every part is different and presents its own challenges, CNC machinists always have to be thinking critically, which makes their careers stimulating.

How to Become a CNC Machinist

NASCAR Tech’s CNC machining program is 36 weeks, teaching students what they need to succeed after graduation. Students learn skills including reading blueprints, interpreting geometric dimensioning and tolerancing, and programming, setup and operation of CNC mills and lathes.

“The thing that would have driven me to go to NASCAR Tech for machining is the speed of the program,” Collier says. “I personally went to a community college for training, and it ended up taking more than five years to get a two-year degree because the school’s and my schedule didn’t line up. You can take 36 weeks and apply yourself, and you will have a major leg up over someone off the street.”

Here’s How to Improve Quality Control in CNC Machining

Looking to improve quality control in your CNC machining? Consider this.

According to Manufacturing Tomorrow:

Computer numerical control (CNC) machines have become a standard in the machining industry. Their accuracy, speed, and ease of use make them indispensable tools. But despite these advantages, they’re still not perfect. Quality control remains an essential step to catch and prevent defects, yet many facilities have sub-par CNC quality control systems.

While errors are far less likely with CNC machines than manual processes, they can still happen. When they do, they can create bottlenecks, lead to waste and, if not caught, hamper client-customer relationships through poor-quality products. Conversely, an effective quality control program improves the entire machining process by stopping these errors.

With that in mind, here’s how manufacturers can improve their CNC quality control.

Check Raw Materials Before Machining

Many people often think of quality checks as the final step in the production process. While final checks are necessary, quality control should start early on, too. Identifying errors after machining means it’s too late to recover costs, but early checks can prevent waste.

One of the most crucial steps in ensuring quality from the beginning is checking material quality. CNC machines can virtually eliminate human error, but if they’re working with low-quality or defective materials, that won’t matter. Even a highly accurate system will produce a poor-quality product if the materials it uses aren’t up to par.

To prevent these mistakes, employees must check the quality of their raw materials before working with them. Sourcing from trusted suppliers will help reduce many material-related issues, but machinists can’t afford to take any risks here. By looking for any cracks, weak points, or other defects in their materials, workers can ensure they use their CNC machines to their full potential.

Use the Appropriate Type of Machine

Not all CNC machines are created equal, and manufacturers should consider this when addressing CNC quality control. Using the wrong machine for a given task can result in more errors, so facilities must be selective about which orders go through which machines. The more complex a product or part is, the more advanced its CNC machine should be.

A three-axis CNC machine, the most common type for mechanical components, is sufficient for simpler designs, but not much beyond that. For more complicated parts or products, workers should use a four- or five-axis machine. More axes give machines more precision, enabling them to perform more complex work without error.

This is not to say that facilities should only use four- or five-axis machines. Balancing work between different machines can help reduce bottlenecks and keep the overall operation efficient. As companies go about this balancing, though, they should send more complicated designs to higher-axis machines.

Employ On-Machine Inspection

Machining operations can also include quality control steps during the CNC machining process itself. Devices called machine tool probing systems attach to CNC machines and inspect quality as they work. This on-machine inspection lets facilities address and correct problems as they arise, preventing errors in the final product.

Probing routines don’t interrupt or interfere with the machining process, so adding them won’t hinder efficiency. What they will do is automatically redirect machines to correct issues they detect in real-time. By catching and correcting errors early, they prevent substantial mistakes, reducing the number of defective or poor-quality parts down the line.

In addition to reducing scrap, on-machine inspection reduces quality control bottlenecks. Since machining time is the primary cost driver for the field, ensuring efficiency in these operations is essential. Tool probing systems prevent rework, reduce total machining time, and produce more consistent quality by minimizing disruptions from end-of-line quality checks.

Use Multiple Quality Control Methods

Just as CNC machining itself isn’t perfect, every quality check method has unique strengths and weaknesses. No one process can catch every error that might arise. To account for this, facilities should use multiple CNC quality control methods, ensuring mistakes missed by one process won’t pass further down the line.

The order of quality control methods is as critical as including multiple options, too. More specifically, human inspections should always be the last stop, as should be the case with all automation-reliant processes. Automated checks are often highly effective, but technical issues can arise and hinder their accuracy. Placing manual checks last can catch these potential mistakes.

One thing to keep in mind here is that too many different methods can create bottlenecks. Facilities don’t need to implement every quality control method possible, but they should use more than one. Generally speaking, one material check before machining, one on-machine inspection process, and one human-driven post-machining check should be sufficient.

If Outsourcing, Look for Vendors With Proper Certification

Not all facilities perform their own CNC machining in-house, but CNC quality control is still relevant. To ensure high-quality outsourced CNC operations, companies should look for vendors with the right certifications. These will vary by industry, but all vendors should at least comply with ISO 9001, a general quality management certification.

Manufacturers in some industries should look for additional certification as well. ISO 13485, for example, demonstrates compliance for medical-grade products, making it essential for those in the health care sector. Similarly, ISO 16949 applies to automotive parts, so manufacturers in the transportation industry should look for vendors that comply with it.

These certifications don’t mean vendors will prevent 100% of possible errors, but they reduce the risk. Obtaining these certifications requires rigorous standards, so it’s a reliable guideline for quality production partners. As such, any facility that outsources CNC processes should understand relevant standards.

Reliable CNC Quality Control Is Essential

An improved CNC quality control system will minimize waste and produce better products. As a result, companies will save money and establish a better reputation among their clientele. Poor quality management can have the opposite effect, making this area a crucial point of focus for any CNC operation.

By following these steps, machining processes can ensure their CNC quality control is as accurate and efficient as possible. They can then take full advantage of these remarkable machines and stand out from their competitors. CNC machining can be an excellent resource, but only if the companies using it abide by high quality control standards.

6 OF THE MOST COMMON CNC MACHINES

What are the most common types of CNC machines?

According to the Universal Technical Institute:

Computer numerical control (CNC) machines play an important role in the manufacturing industry. These complex machines are controlled by a computer and provide a level of efficiency, accuracy and consistency that would be impossible to achieve through a manual process.

Operations that were impossible years ago are now easy thanks to CNC machining. Just as there are many different parts that CNC machines can make, there are also various types of CNC machines used to accomplish this. Each machine differs in construction, the way they operate and the types of product they can make.

Keep reading to learn all about the different types of CNC machines and their unique functions:

What is CNC Machining?

CNC machining can be defined as a process in which pre-programmed computer software dictates the movement of factory machinery and tools. As a result, manufacturers can produce parts in less time, reduce waste and eliminate the risk of human error.

This manufacturing process is used to control a wide variety of complex machinery, which will be discussed in this article. Essentially, CNC machining makes it possible for three-dimensional cutting to be completed by following one set of prompts.

The Different Types of CNC Machines

CNC machines are designed to manufacture a wide variety of items. As such, there are several different types of commonly used CNC machines.

It’s important to know that these are not your average machines. They require the skills of a trained professional to be able to produce high quality commercial products. All of the following machines use G-code, which is the language that a CNC machine understands. Each type of CNC machine caters to a specific purpose.

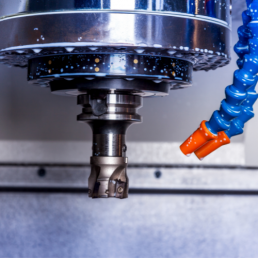

CNC Milling Machine

One of the most common types of CNC machines, a CNC mill utilizes computer controls to cut various materials. Mills can translate specific programs of numbers and letters in order to move the spindle in various ways.

Many mills use what is known as G-code, which, as mentioned, is a standardized programming language recognized by most CNC machines. A CNC mill can have a wide array of functions, such as face milling, shoulder milling, tapping, drilling and turning. Most CNC mills come in three to six-axis configurations.

A CNC mill is very large compared to other tools and can be quite costly. Some CNC milling machine manufacturers include Okuma, HAAS and DMG Mori.

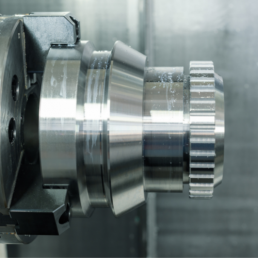

CNC Lathe

A lathe is a CNC machine that functions to cut work pieces as they are rotated. CNC lathes can make precise cuts quickly by using various tools.

These CNC machines are quite effective in the precision they offer compared to manual lathes. They often have fewer axes than CNC milling machines, and are therefore smaller in size and more compact.

CNC lathes come with similar controls to those of CNC mills and can read both G-code and other proprietary programming languages. Some of the most common CNC lathe machine manufacturers include HAAS, Mori Seiki and Okuma. The framework of CNC lathes is similar to manual lathes.

What is a CNC Router?

A CNC router is a machine that is very similar to the commonly used handheld router utilized for cutting various materials. This type of CNC machine can aid in the cutting of steel, wood, aluminum, composites, plastic and foam.

A CNC router is similar to a CNC mill. It comes with the ability to use computer numerical control to route tool paths that enable the machine to function. CNC routers reduce waste and increase productivity by producing various items in a much shorter amount of time than other machines.

Most routers can operate on a particular material in all three dimensions, and are great for smaller projects and the creation of prototype models and complex designs. You can also find three axis, four axis, five axis and six axis routers.

What is a CNC Plasma Cutter?

The process of plasma cutting involves the cutting of a material using a plasma torch. This method is most commonly used to cut heavy materials, such as steel and other forms of metal.

With a CNC plasma cutter, gas is blown at a very high speed from a nozzle. While this is being done, an electrical arc forms through the gas coming out of the nozzle to the surface that is being cut.

This converts some of the gas into plasma, and these plasma temperatures range from 10,000-50,000 degrees. The plasma is hot enough to melt whatever material is being cut, and it blows away any molten metal from the site of the cut.

In terms of shape and size, CNC plasma cutters are very similar to CNC routers. These machines only work with two-dimensional shapes.

CNC Electric Discharge Machine

Electric discharge machining, or EDM for short, involves creating a specific shape within a certain material by using electrical discharges, or sparks.

In this process, the material is removed from a specific work piece by a series of recurring electrical discharges between two electrodes. These electrodes are separated by a dielectric fluid, which often receives an electric voltage. In this machine, the material is placed in between two electrodes and the machine then calculates to see the amount of electrical discharge each electrode needs to produce.

What is a CNC Laser Cutter?

Last but certainly not least, there are CNC laser cutters.

These types of machines are similar to CNC plasma machines—the only difference is that lasers are mostly used for cutting and are great when it comes to cutting metals, plastic or hardwood. Depending on the density and strength of the material, the intensity of the laser can be adjusted.

Applying This to Your Career

As you can see, there are various types of CNC machines, all of which serve different functions. As a CNC operator, machinist or programmer, it’s important to have an understanding of how these machines work and what they are capable of in order to get the job done right.

If you’re wondering what career opportunities exist in the CNC industry, be sure to check out our CNC career guide. From aerospace to medical to oil and gas, CNC machines are used in a variety of fields, which opens the door to many different career opportunities in each of these industries.

If you’re looking to pursue a career in the CNC industry, it’s important to have the right training. UTI offers a 36-week CNC Machining Technology program, where you can gain hands-on training and high-tech skills needed to prepare for a career as a CNC machinist.

Created in conjunction with Roush Yates Engines, a leading brand in the industry, you’ll learn everything from reading blueprints to the setup and operation of CNC mills and lathes. This program begins every six weeks, so you may be able to start your training sooner than you think.

CNC’s changing role in aerospace factory automation

CNC is helping to shape the future of aerospace factory automation.

According to Aerospace Manufacturing and Design:

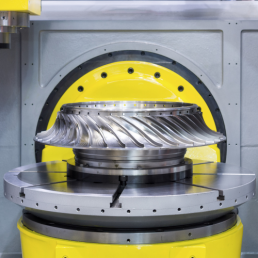

In automated aerospace assembly, computer numerical controls (CNCs) are better able to address complex interpolated motion than programmable logic controllers (PLCs). CNC technologies are finding increased application in complex airframe alignment tooling, robot control, additive machining, fiber placement and tape laying, and 5-axis machining.

As CNC use grows, manufacturers must integrate them into product lifecycle management (PLM), manufacturing execution systems (MES), and manufacturing operations management (MOM) environments. To optimize production processes, MOM software focuses on efficiency, flexibility, and time-to-market, including:

- Integration with order management

- Advanced planning, scheduling

- Quality management

- Tracking and tracing

- Supervisory control and data acquisition (SCADA)

- Research and development (R&D) management

As CNC technologies and software management tools have grown individually – often counter-productively – challenges have emerged:

- Production planning, operational management of a variety of machines

- Optimizing performance, flexibility of PLC-, CNC-based production machines

- Extracting data for monitoring, putting the right information back into the machines, proper human machine interface (HMI)

- Managing operator skill levels on variety of controllers

- Maintaining variety of machines, spare parts

One platform, all technologies

Aircraft parts machining and assembly technologies can be standardized using today’s CNC platforms. With system openness, technology can be adapted to fit the machine tool and other production machining technologies – not only for traditional metal cutting, but for composites production. In-cavity fiber molding, composite tape laying, ceramic, and powdered metal additive processes use CNC technology with adaptive modes and high customization for motion control and data transmission.

Using CNC as a single standard for various production technologies enables:

- Uniform operation, programming of various machines

- Machine data integration on a standard communications platform; consolidated information from various brands of sensors, motion components

- Consistent, global programming, operations, maintenance training

The open architecture of advanced CNC comes from standard systems, the virtual numeric control kernel (VNCK) for virtual simulation, and simple language commands on the HMI – all engineered on the control at NC language level. PLCs can be adapted via standard engineering tools, and CNC applications can be supplemented with software tools from third-party suppliers – tool and process monitoring systems, measurement systems, tele-services, and video monitoring systems.

High performance 5-axis machining

To machine complex parts, CNC software can improve performance and precision, since machine kinematics are no longer the sole determinant when machining. The CNC can adjust interpolation of machine axes to integrate with orientation vectors to the workpiece, increasing surface finish quality, optimizing cutting speed, and increasing efficiency.

Workpieces can be programmed in Cartesian coordinates and system-specific cycles, and function macros can automatically calculate machine axis movement.

Volumetric compensation

Volumetric compensation software (VCS) implements compensation at machines with five axes, if the tool with two rotary axes can be orientated to the workpiece. Measured error compensation of the linear axes is calculated, depending on the position of the tool, to the tool center point.

For use on 3- and 5-axis portal milling machines, VCS expands CNC technology by implementing volumetric compensation of 21 geometrical machine errors on a Cartesian machine tool.

Geometrical machine errors cause tool-center-point-offset and tool-orientation error. Because of the positions of the rotary axes, their mutual offsetting, and the orientation of the tool, parts such as turn and swivel heads may exhibit systematic geometric errors. Small errors in the guide system for feed axes – positional, horizontal and vertical straightness, pitch, yaw, and roll – will arise in every machine.

In a 3-axis machine, 21 geometry errors can be ascribed to the tool holder – six error types per linear axis plus three angle errors. Deviations form volumetric error, the deviation of the real machine tool center point (TCP) position from an ideal, fault-free machine. Qualified CNC technicians can determine volumetric errors onsite using laser measuring devices. Entire measuring curves are recorded, as individual error sizes are dependent upon the position of the relevant feed axis and on the measuring location. For example, errors attributed to the X-axis turn out differently if the Y-axis and Z-axis are in different positions – even if the errors are at the very same position on the X-axis. On today’s CNC, rotary axis errors can be determined in just a few minutes so the machine’s accuracy can be constantly checked and corrected, even during production.

System integration

Digitalization of industrial processes will eventually encompass every step of product life cycle – design, production planning, engineering, execution, and a network of global services.

Multi-axis machining workflow is typically characterized by the computer-aided design (CAD), computer-aided manufacturing (CAM) CNC process chain. Enhanced CAM with specific post-processing combines realistic machine simulations driven by a VNCK to create a digital twin.

CNC units can be networked to transmit data to the cloud for monitoring and corrective action, tracking back from production output and maintenance alerts on the machine to integration with CAD files and part prototypes. Production of components and assembly of finished aircraft benefit from the controls on the machines. Core elements of a full digital enterprise system begin to emerge from the data generated by the machine controls.

Simulation

Advanced simulation software and virtual production subjects the process chain to a simulative analysis from the CAD/CAM system to the workpiece surface. Instead of repeated testing on an actual machine, programs can be optimized in computer simulation, with the exception of the numerical control program, which is simulated on a real machine.

Virtual production can be performed in three steps:

- Analysis of the data quality as provided by the part program

- Execution of the part program by the numerical control (NC) where set-point positions on the NC output are evaluated and velocity can be optimized and controlled

- Simulation based on characteristic features of position-controlled drives including machine dynamics

Virtual production reduces machining times, improves surface finish, and shortens start-up times for new workpieces.

The mechatronic twin can be run with only a CNC simulator, through Mechatronics Concept Designs (MCD), a Siemens machine design tool. Production times, collision avoidance between spindle and workpiece, tool path optimization, and machine kinematics can be virtualized and evaluated prior to test runs. This simulation can drive the creation of G-code programs on the final machine.

Motors, drives, shafts, slides, cam discs, spindles, etc. are stored with all technical data and animated in the MCD. Positions, feeds, and speeds from the central processing unit (CPU) can be transferred to the design engineering computer in the MCD.

The 3D model can be operated like a machine tool via the CNC control. In manual mode, individual axes can be triggered. In production mode, axes can be moved synchronously toward each other via electrical cam discs. Machine functions can be actualized, checked, and optimized.

Communication at all levels

With Profinet, the Sinumerik 840D sl CNC integrates with the Siemens Totally Integrated Automation (TIA) environment – from field level to production level to manufacturing execution level.

The TIA portal’s engineering framework supports planning, programming, and optimization of machine and process tasks. Consistent, standardized operating enables users to program and integrate all Siemens controllers, distributed input/output (I/O), HMI, power supply and distribution, drives, network components, motion control, and motor management. CNC data seamlessly channels through this engineering tool to a centralized workstation or control room.

With smart library shared data storage, users can tap existing libraries of proven CNC code to program universal hardware and software functions, and they can develop and store libraries of their own proprietary code.

The digital factory and digital enterprise remain key targets for aerospace, and the power of the CNC on all operational machine motion control, data gathering, and communications levels continue to feed that process, evolving at light speed.

Waterjet, Oxycut, Plasma or Laser, Which Cutting Technology Should I Use?

Wondering what cutting technology is best for your next project?

According to Manufacturing Tomorrow:

However, with recent breakthroughs in the laser world of fiber cutting technology, there is technological competition taking place between high definition plasma, CO2 laser, and the aforementioned fiber laser.

Which is the most economical? The most accurate? For what kind of thickness? How about material? In this post we will explain the characteristics of each, so that we are best able to choose the one that best suits our needs.

Waterjet

This is an interesting technology for all those materials that might be affected by heat when performing cold cutting, such as plastics, coatings or cement panels. To increase the power of the cut, an abrasive material may be used that is suitable for working with steel measuring greater than 300 mm. It can be very useful in this manner for hard materials such as ceramics, stone or glass.

Punch

Although laser has gained popularity over punching machines for certain types of cuts, there is still a place for it due to the fact that the cost of the machine is much lower, as well as its speed and its ability to perform form tool and tapping operations that are not possible with laser technology.

Oxycut

This technology is the most suitable for carbon steel of greater thicknesses (75mm). However, it is not effective for stainless steel and aluminum. It offers a high degree of portability, since it does not require a special electrical connection, and initial investment is low.

Plasma

High-definition plasma is close to laser in quality for greater thicknesses, but with a lower purchase cost. It is the most suitable from 5mm, and is practically unbeatable from 30mm, where the laser is not able to reach, with the capacity to reach up to 90mm in thickness in carbon steel, and 160mm in stainless steel. Without a doubt, it is a good option for bevel cutting. It can be used with ferrous and non-ferrous, as well as oxidized, painted, or grid materials.

CO2 Laser

Generally speaking, the laser offers a more precise cutting capability. This is especially the case with lesser thicknesses and when machining small holes. CO2 is suitable for thicknesses between 5mm and 30mm.

Fiber Laser

Fiber laser is proving itself to be a technology that offers the speed and quality of traditional CO2 laser cutting, but for thicknesses less than 5 mm. In addition, it is more economical and efficient in terms of energy usage. As a result, investment, maintenance and operation costs are lower. In addition, the gradual decrease in the price of the machine has been significantly reducing differentiating factors in comparison to plasma. Due to this, an increasing number of manufacturers have begun to embark on the adventure of marketing and manufacturing this type of technology. This technique also offers better performance with reflective materials, including copper and brass. In short, the fiber laser is becoming a leading technology, with an added ecological advantage.

So then, what can we do when we are carrying out production in thickness ranges where several technologies might be suitable? How should our software systems be configured in order to obtain the best performance in these situations? The first thing we must do is to have several machining options depending on the technology used. The same part will require a specific type of machining that ensures the best use of resources, depending on the technology of the machine where it will be processed, thus achieving the desired cutting quality.

There will be times when a part can only be executed using one of the technologies. Therefore, we will require a system that uses advanced logic to determine the specific manufacturing route. This logic considers factors such as the material, the thickness, the desired quality, or the diameters of the internal holes, analyzes the part that we want to manufacture, including both its physical and geometric properties, and deduces which is the most suitable machine to produce it.

Once the machine has been selected, we may encounter overload situations that prevent production moving forward. Software that features load management systems and allocation to work queues would have the capacity to choose a second machining type or a second compatible technology to process the part with another machine that is in a better situation and that allows manufacturing in time. It may even allow for work to be subcontracted, in the event that there is no excess capacity. That is, it will avoid idle periods and will make manufacturing more efficient.

As we can see, the cutting specialization and the use of different cutting technologies for each particular case also involves having CAD/CAM software that is able to address the use and combination of these machines within a single system. In addition, it must include the possibility of assigning and managing the ideal machine, combining both technology and the workload situation. It should also always allow us to manufacture with the quality that is needed, in the most economical manner possible, and respecting delivery times.

Why Source in India

We’ve learned a lot during this pandemic. Global supply chains were significantly disrupted during these times, causing companies to rethink their global supply chain strategies. Companies like Jaguar and Land Rover were affected from their UK to Chinese markets and had to rethink how they global sourced. Even companies like Samsung, who had moved production to Vietnam, were feeling the effects.

Now more than ever, companies need to rethink how they do business and where they source their production means. With tariffs rising in China, the country has no longer become the best place to manufacture.

Companies have moved on to different countries such as Vietnam. Who is developing infrastructure to keep up with growing interest but is struggling to build adequate transportation infrastructure with congested roads and ports.

So, where should a company manufacture? China and Vietnam are not the only options for a thriving business. India is a cost-competitive alternative in the manufacturing market.

Why India

Low labor costs are the most crucial reason for global sourcing. Manufacturers overseas offer their services at a highly competitive price, and this is especially true in India.

Taking aside lower labor costs, there are plenty of other reasons to manufacture in India. Some examples include:

- Access to technology and hardware

- Access to research tools, design expertise, and skilled labor

- Sourcing raw materials

- Manufacturing efficiency that is hard to find

- Efficient quality control

- Sourcing potential strategic partners and business talent

India demographics

India produces the highest number of engineers in the world. You can be assured that the overseas partners you engage with will are educated in the most up-to-date working processes and labor practices. Indian engineers are known to have strong expertise in operating the most modern mechanical equipment in the world. Also, communication is easy with India as most of India’s engineers are bilingual, English being one of the most prominent languages.

An automotive boom in India

India became the fifth-largest vehicle retail seller in 2019, with sales reaching 3.81 million units, which means that India has expertise in producing automotive parts. According to the Department for Promotion of Industry and Internal Trade (DPIIT), the industry has received a foreign direct investment (FDI) credit of $24.21 billion between April 2020 and March 2020.

Casting in India

The automobile industry accounts for 40% of all casting produced in India. While casting formation reached 11 Mn tonnes in 2018 and has a planned increase of approximately 12.7% from 2018 until 2023. Indian manufacturers are experienced in castings and work with a variety of materials. As of 2018, aluminum castings comprised 15% of total casting in the country.

CNC Machining in India

CNC machining is a subtractive process that utilizes computerized controls and machine tools that remove layers of material from a stock piece. CNC machining is a popular process in India that is cost-competitive. The market size is expected to grow by 1.9 billion from 2019-2024 at 13% CAGR.

The combination of a skilled labor force, ease of communication, and India’s experience in different types of manufacturing make it a fantastic resource for global sourcing. However, the logistics of working with overseas partners can be overwhelming and tiresome. It’s best to partner with a global sourcing expert like Aerostar. We have trusted suppliers and the expertise to manufacture your part at the best price and highest quality.

Have a part and ready to take the next step? Submit a quote today. https://demo.totalwebpartners.com/aerostar/request-quote/

Top 5 Reasons to Choose a Global Sourcing Partner

Top 5 Reasons to Choose a Global Sourcing Partner

You’ve spent the time and resources making a fantastic product, and now it’s time to manufacture. But the question is with whom will you manufacture? There are many things you need to know before you can choose.

Will you produce domestically or internationally? Can you trust your supplier (whether domestic or international) with your parts or assembly? Are you comfortable with the capability of the manufacturing plant? Does your supplier have the right kind of systems, certifications, and experienced personnel in place? Does the manufacturer handle the whole supply chain, and are they willing to warehouse? Do they have contingency plans in place, just in case? If they are international, do they have a presence in the United States to answer any questions in our time zone?

With so many questions on your mind, have you considered having someone else manage your global sourcing? We’re here to tell you the top 5 reasons why you should choose a global sourcing partner.

1. Control

Having a global sourcing partner allows you, the buyer, to take control of production without having to manufacture the part. The partner will go out and find suppliers and bring you back options that fit your standards and budget. A good global sourcing partner knows how to communicate with suppliers to get the results you want. Generally, they should be experienced in global manufacturing, associated supply chains and have tackled most of the related challenges in the past.

2. Get to Know Your Supplier

A good partner will inform you about the manufacturer’s qualifications. They will notify you about the offices, production lines, warehouses, and testing. You may even be invited to a plant tour. The best partners will make you feel informed every step of the way. They are extension of your purchasing, engineering, quality and supply chain departments without costing you separately for each such department.

3. Communication

A good partner will communicate with you. They will get to know the part and ask questions. A good partner will also communicate with the supplier, negotiate prices on your behalf, work out any kinks in the system or problems that might arise. They will track the parts from launch to when the part gets delivered to your dock.

4. Cost savings

Going overseas is generally cheaper, and with the extensive installed manufacturing capacity available in the low cost countries like India and other Asian countries, it is easier to pick up unused capacity without having to invest in new machinery and other infrastructure. A global sourcing partner will ensure that your product is produced at the best price with the best quality.

5. Supplier Representation

The global sourcing partner doesn’t just represent your company. They represent the supplier as well. You will be assured that your global sourcing partner will find you the highest quality suppliers and hold them to high standards.

Above are just some of the reasons to partner with a global sourcing partner like Aerostar Manufacturing. Ready to take the next step? Submit a quote to Aerostar Manufacturing, your trusted global sourcing partner.

The Benefits of CNC Machining For Businesses

Read up on these top three reasons you should use CNC machining for your next project.

According to itechpost:

Computer Numerical Control, often shortened to CNC, machines are a cost-effective way to increase the quality of your products, while they can also increase the operational efficiency of a company. This is also the case when outsourcing the production to a CNC machine shop, because CNC machines reduce overheads. Furthermore, they improve your bottom line performance because the production process is quicker, while the products are consistently of a higher quality as well. The same thing happens to your business when you use CNC services. CNC machining is already used by various companies, partially because they want to experience the benefits of this manufacturing method. A few examples of these advantages are mentioned below.

Operational versatility and simplicity

Because you use computer programming when it comes to Computer Numerical Control machines, you are capable of controlling essentially any tool. These are used to cut, form, and shape the workpiece that is being used, which is a block of a certain material. By doing this, a product will be created with total precision in a short amount of time. Usually this will take much longer, which is especially the case when you decide to use traditional manufacturing processes. The operator of the CNC machine will have to key an instruction program into the computer. Afterwards, he or she needs to insert the needed tools and allow the computer to do the cutting automatically, although other CNC machining operations can be employed as well of course.

Versus manual machines

Instead of the Computer Numerical Control machines you could also use manual machines, of course. These are machines that you have to control by hand, which sets them apart from CNC machines. After all, a CNC machine is controlled by a computer. Manufacturing companies benefit enormously from these machines because they are capable of producing complex and irregular shapes. This includes three-dimensional designs for example. Usually these products cannot be made using manual machining. Because of this, several types of CNC machines are already used in many different industries. It is highly important to select the appropriate CNC machine for your business, since this will essentially decide how your products will be made in the future. By outsourcing the production process this is not really the case, since a machine shop offers a lot of different CNC machines.

Wide spectrum of CNC machines

As mentioned before, there are a lot of different CNC machines that can be used. This includes turning centers or lathe machines, machines used to produce cylindrical products. Turn mill centers on the other hand allow both milling and turning functions, while grinding machines are used to grind metal components. On top of that, they can also polish metal and smooth metal surface finishes. Five-axis CNC machines are special machines, these are capable of moving in five directions at the same time. On top of that, machines can be custom built for specific CNC operations. This can include CNC routers, just like CNC plasma cutters for example.

Forging the Future of Transportation

The forging industry is shaping the future of transportation.

According to Forge Mag:

As the domestic automobile and light-truck markets gradually trend toward various electric vehicle (EV) designs, forgers are faced with both challenge and opportunity. This article shows how the opportunities presented by the EV industry are being met by Anchor Harvey through the launch of its Electric Vehicle Workgroup.

Major automotive OEMs and new startups alike are already well in pursuit of the next generation of transportation. The automotive industry is currently shifting to new technologies that have already started to change the way many people think about transportation. Developing technologies – such as electrification, automation and connectivity – are increasingly being included in new vehicles, disrupting the long-established means by which autos have been powered, operated and, perhaps most importantly, manufactured. However, the potential market disruption also presents an opportunity for American manufacturing in general and the forging market in particular.

ICE vs. EV

To understand the disruptions and opportunities in the coming shift from the internal combustion engine (ICE) to electric vehicles (EVs), it is important to first discern the differences between the two systems. While ICE vehicles and EVs may, at a glance, look similar, they are remarkably different under the hood and floorboards. In an electric vehicle, the fuel tank is replaced by a battery pack, and the internal combustion engine is replaced with one or more electric motors. Similarly, the ICE vehicle’s multi-geared transmission and clutch are replaced with a fixed, single-gear gearbox. EVs also do not require any form of onboard emissions control because they do not produce any carbon emissions.

The result is that EVs have far simpler motors than ICEs in terms of both their operations and manufacturability due to EV powertrains having fewer moving parts and less mechanical complexity. According to UBS, the electric motor on Chevy’s Bolt has three moving parts, which is in sharp contrast to the 113 moving parts in the internal combustion engine of a Volkswagen Golf. Despite having fewer components and reduced intricacy, EVs nevertheless present new challenges that major automotive institutions and startup companies have yet to solve. Currently, the difficulties being faced fall into two primary areas: power-to-weight ratio and expensive component supply, which are the same areas that present opportunities for forging companies.

The Weight of Power Battery Burdens

Range anxiety – the concern that a vehicle may have insufficient range to reach its intended destination – remains one of the most significant obstacles to the widespread adoption of electric vehicles. The cause of this anxiety, a dilemma currently faced by every consumer-facing EV company, is the current power-to-weight ratio of electric vehicles. Due to their large lithium-ion battery packs, EVs are hefty vehicles. In some cases, they can be heavier than their traditional ICE competitors. Automotive magazine Car and Driver compared Audi’s 2019 e-tron to a 2019 Ram 1500 pickup in a notable example and found that the “e-tron, with its liquid-cooled 95.0-kWh lithium-ion battery, weighed in at 5,843 pounds – 78 pounds more than the 5,765-pound long-bed Ram 1500.”

Built for Range, Not Anxiety

The power-to-weight challenge of increasing range and eliminating anxiety that faces EV manufacturers has only two possible solutions. They can either increase battery power or decrease vehicle weight with advancements in energy-storage technologies such as solid-state batteries and ultracapacitors. Other emerging technologies are in the early stages of development or exceedingly cost-prohibitive, so expect that most plug-in hybrids and all-electric vehicles will continue to use standard (and notably heavy) lithium-ion batteries for the foreseeable future. This provides an opportunity for forging companies to lead the way in reducing, or even eliminating, range anxiety through the manufacture of high-strength, lightweight components.

With the reduction of vehicle weight being such an important factor for increasing EV range, forging companies able to get into the EV space early will be able to demonstrate themselves as invaluable partners to automakers. By delivering lighter components and overcoming the power-to-weight ratio dilemma, forging companies like Anchor Harvey and its EV Workgroup are already working to enhance mileage gains and pave the road ahead for the next generation of electric vehicles.

The Price of Success Supply-Chain Struggles

The second issue faced by automotive OEMs and EV startups is the cost of materials and components. With relatively few exceptions, most of today’s EVs are priced high and aimed at luxury-car buyers. According to data from the Natural Resources Defense Council, the average electric-car price in the U.S. is $19,000 higher than the average price of a gasoline-powered vehicle. The higher prices of EVs can be attributed to several factors, including expenses associated with prototyping; research and development; and, not insignificantly, the cost of rare-earth metals used in EVs such as neodymium, dysprosium and praseodymium.

A study conducted by Dr. Ryan D. Long, a mining analyst at the Edison Research Group, makes a note of how “[t]he mid-term growth potential of EVs and neomagnets could drive demand for rare-earth elements to levels never seen before. Obtaining secure and sustainable production outside China must be front and center in the thoughts of end-users.” Growing demand for rare-earth metals isn’t the only production issue EV manufacturers are confronting. Global supply-chain issues have also led to skyrocketing prices in steel and numerous other staple manufacturing materials. Given these compounding issues, it is of little surprise that EV manufacturers are experiencing difficulties in bringing down vehicle prices.

Domestic Opportunities

Supportive policies and government initiatives have aided in cost reductions for electric vehicles, but prices have remained high. There is no potential cure-all for the cost of EVs that run on conventional lithium-ion batteries, but there are ways for EV manufacturers to begin bringing prices lower, which presents a second significant opportunity for the forging industry.

The variety of solutions that forging offers commonly leads to forged components being less expensive than alternatives. This can be of considerable assistance to OEMs and EV startups to lower their overall production costs as they look to bring down the MSRPs for electric vehicles. American forging companies are well positioned to help EV manufacturers adjust their supply chains to a new trading landscape by providing value in the form of lower-cost or cost-competitive components. For forging companies like Anchor Harvey and others with an entirely domestic supply chain, the opportunities are still greater.

Using domestically sourced materials and American-made forged components enables EV manufacturers to secure shorter lead times for parts with little or no overhead inventory requirements and a lower raw-material price, particularly when the total cost of ownership is taken into consideration. With cost-competitive forged components and the ability to provide better lead times than overseas competitors, U.S.-based forgers are uniquely positioned to meet the current price-specific needs of EV manufacturers.

In addition, American forging companies can provide valuable services to EV OEMs such as consultation, design engineering, quality inspection and rapid prototyping. According to the International Energy Agency, up to 130 million battery-powered EVs and 90 million plug-in hybrid vehicles are expected on the roads globally by 2030. The American forging industry can grow along with the market and supply components at scale as consumer demand for EVs continues to increase during the years ahead.

Forge Forward

The process of forging has existed for thousands of years and will continue to provide components to industries and companies across the globe for thousands of years to come. Undoubtedly, many forgers will (or perhaps already have) begin to mourn the internal combustion engine’s demise. While the transition from forging components for ICE vehicles to EVs will require adjustment and flexibility, it is the next step forward for the forging industry. With the high-strength, lightweight, cost-competitive, range-advancing benefits that forged components provide, the forging industry will help the future take shape.

Anchor Harvey, which has both a passion for developing sustainable electric vehicles and a century of forging expertise, launched its Electric Vehicle Workgroup because of the opportunities presented by the EV industry. The EV Workgroup is partnering with name-brand OEMs, emerging startups and niche producers to deliver high-strength, lightweight components for the next generation of transportation. The forging industry has continuously adapted over the centuries, which is why we at Anchor Harvey are here to forge forward by delivering components that help electric vehicles go farther and last longer.